Understanding Wave Picking in Modern Warehousing

To understand wave picking in modern warehousing, we need to understand wave picking meaning. Wave picking is a warehouse order fulfillment method where various customer’s orders are grouped and released in bulk or wave rather than being picked individually. Wave picking warehouse uses this approach to reduce blockages, improve labor utilization, and ensure orders are shipped in sync with carrier deadlines. By incorporating Wave management system (WMS) with wave logic, businesses can access faster and more accurate fulfillment.

The Flow of Operations in Wave Picking

Wave Picking warehouse is a an organized order fulfillment method that follows three clear steps.

Pre-wave Picking: Pre wave picking is the first step of Wave picking, where orders are grouped as per certain criteria which includes, shipping deadlines, item availability, and more.

Performing Wave picking: It is the act of picking orders. Instead of paper slips, the pickers use handheld scanners that is linked to WMS. These devices show a digital pick list to the pickers and guide them to the right location and confirm that each step is more efficient with technology.

Post wave Picking: The third and final step is Post wave picking that occurs after the order are picked. It involves sorting, packing, and quality checking for a accurate and efficient order fulfillment before shipping.

Wave Picking vs. Batch Picking: Key Contrasts

One of the common questions that appears while understanding Wave Picking meaning is how is different from Batch Picking. Batch Picking is about collecting and grouping orders with similar SKUs, to reduce walking time, whereas wave picking introduces a scheduling layer, orders are picked as per the priority. In practice, wave picking warehouse may uses both practices, i.e. batch picking to optimizing travel, and wave picking to align with shipping schedules.

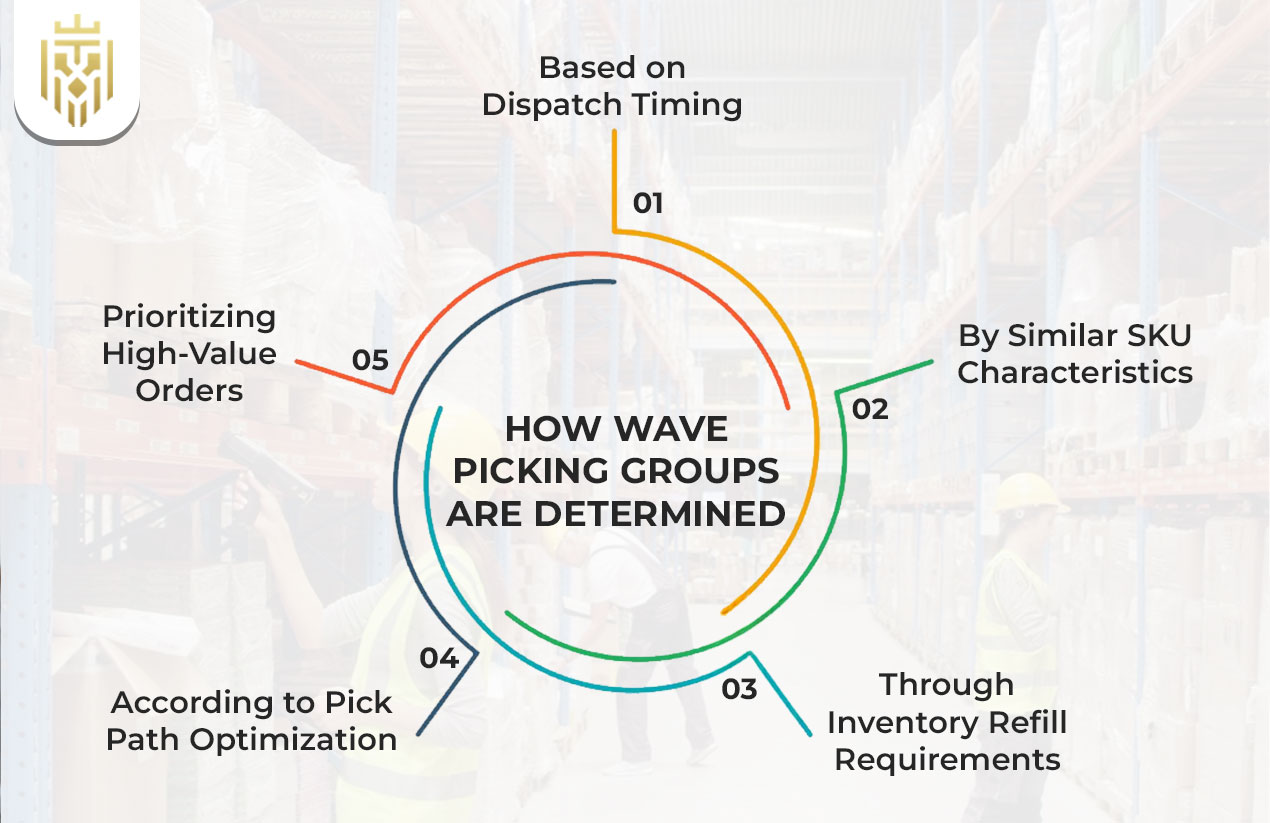

How Wave Picking Groups Are Determined

The wave picking process is not a random process, the procedure is done with carefully planning to match business requirements and shipping deadlines. A warehouse management system (WMS) normally works by analyzing order data and creating groups, or waves, based on certain rules.

The end goal of wave picking is to make picking more efficient by reducing travel time, balancing workloads, and ensuring orders are ready to dispatch on time. For instance, high valued or urgent orders are grouped into separate waves, while regular or bulk orders are scheduled for later. Setting a correct criteria helps the ware houses to optimize both speed and accuracy while avoiding blockages during peak times.

There are several criteria to group wave picking. Following are some of them:

Based on Dispatch Timing

One of the most common grouping is based on dispatch timing. In this orders are grouped according to their shipping timings/deadlines so that they are picked, packed, and ready when carriers need them. For example, same day delivery orders are grouped in an early wave, while regular shipping orders are scheduled later. This prevents last minute rushes, and ensures that prioritized orders leave on time.

By Similar SKU Characteristics

Grouping orders with similar SKUs is another way of wave groups. In this products of the same type or category are picked together, it avoids picker travel time and speeds up the procedure. If multiple orders contain the same size of a popular item, those orders are placed in a single wave.

Through Inventory Refill Requirements

Waves are also created around inventory refill needs. It means if a certain items are running low in forward picking areas, warehouses may schedule waves after restoring those products. This ensures that pickers don’t face stock outs in the midst of the wave. Warehouse maintain a smoother flow, reduce idle time, and prevent delays by aligning with refill cycles.

According to Pick Path Optimization

Wave groups are also categorized according to pick path optimization, to minimize picker travel distance inside the warehouse. By this order sequencing based on the most efficient pick path, warehouses reduce on unnecessary movement and speed up fulfillment. Orders located in the same area or aisle are grouped into one wave, so that the pickers move in a logical flow. This method saves time and boosts overall productivity.

Prioritizing High-Value Orders

Warehouses create waves based on priority. This means grouping high valued or critical orders in one group. These may include premium customer purchases, medical items, or urgent B2B shipments. By dividing them into priority based waves, warehouses ensure the orders have faster delivery process. This wave picking method improves customer satisfaction and also safeguards revenue by reducing the chance of errors or delays on the most important shipments.

Different Approaches to Wave Picking

Wave Picking doesn’t have a single approach. Warehouses apply the method differently based on order profile, size, delivery time and customer needs. Depending on the priorities, waves are released one order at a time. Each approach offers different benefits, whether it is reducing travel time, balancing workloads or aligning with carrier schedules. By choosing a right approach, warehouses can adapt wave picking to maximize accuracy and speed in fulfillment.

One-at-a-Time Order Release

With One-at-a-time Order Release approach, waves are created for single orders released individually. It’s one of the most useful methods for warehouses dealing with urgent methods for warehouses dealing with urgent or express delivery shipments where accuracy matters more than volume. When pickers are focusing one order at a time without any distractions it results in reducing any chance of errors. This approach may not maximize efficiency for large operations, but it provides reliability and speed for crucial orders that needs immediate attention.

Consolidated Multi-Order Release

In consolidate multi order release warehouses group different orders into single wave to maximize efficiency. Here pickers handle multiple orders in one trip, often use multi tote carts to keep the orders organized. This approach minimizes travel time, improvise picking speed, and is especially effective to handle high volume during peak time. It does require more coordination to keep orders separately, but it also boosts productivity in busy wave picking warehouses.

Division by Warehouse Zones

In this approach wave picking is organized by specific zone of the warehouse. Foe each zone one picker is assigned, and orders are divided so that items from the same spaces are picked together. This minimizes cross- warehouse movement, keeps operation more organized, and helps balance workloads across staff. Once items are collected from all areas, they are then placed for packing and shipping. This method is favorable for large warehouses.

Time-Phased Picking Slots

Time phased picking slots arrange waves based on specific time intervals during the day. In this method orders are released in scheduled waves that line up with carrier pickups, changes in the shifts, or peak order volumes. This method creates a stable workflow, prohibiting barriers and last minute rush.

Equipment-Based Wave Assignments

In this method, wave groups are created based on their type of equipment required for picking. For example, bulky orders may need forklifts, while for smaller goods, carts or hand held devices can be used. Aligning orders with the right euipments helps in reducing delays. This method also reduces congestion, as each piece of equipment is allocated to a specific wave rather than competing for space at the same time.

Why Warehouses Choose Wave Picking

Warehouses use the wave picking method because it maintains a balance between efficiency and accuracy in order fulfillment. By grouping items into planned waves, operations become more predictable, workloads are equally distributed, and shipping deadlines meet easily. This structured process reduces chaos which results in eliminating errors and delays.

Improved Workflow Balance

Wave picking helps warehouses distribute tasks evenly across teams. Instead of overpowering pickers with random orders, waves are scheduled to match workforce capacity and shipping priorities.

Lowered Congestion at Pick Points

One of the biggest advantages of wave picking is that it leads to avoid traffic in high demand areas of the warehouse. By grouping orders into organized waves, pickers are directed to different zones in a controlled sequence, that prevents everyone from overcrowding the same pick up points at once.

Higher Picking Precision

Wave picking widen accuracy rate by using structured pick up lists and guided workflows. Instead on relying on random picking, each wave is planned so that the pickers know the exact SKUs to collect. This precision not only improves customer satisfaction but also reduces the costs of returns and rework for the warehouse.

Easier Shift-Based Scheduling

Wave picking makes order process simpler with workforce shifts. Since waves can be planned in advance, managers can release them at the start, middle, or end of a shift depending on the order’s priority and staff levels. This flexibility in ensuring deadlines are met without overburdening employees, at the same time allowing a smooth handover between shifts.

Greater Visibility in Fulfillment Metrics

It provides warehouses with clear insights into performance and progress. Since each wave I traced separately, managers can monitor accuracy rates, completion times, and resource utilization more easily. This data improves forecasting and refine future wave strategies.

FAQs

1. What is wave picking in warehousing?

Wave picking is an order fulfillment strategy where a wave picking warehouse releases orders in bulk at scheduled intervals. This results in improving efficiency and accuracy.

2. What is wave picking meaning in logistics?

Wave picking means when orders are grouped into timed waves, that allows pickers to fulfill multiple orders efficiently while aligning with shipping schedules.

3. How is wave picking different from batch picking?

Batch picking focuses on grouping SKUs, whereas wave picking focuses on scheduling. A warehouse may use both wave picking as well as batch picking together for maximum efficiency.

4. Which types of wave-picking methods are commonly used?

Commonly used methods include time-phased slots, zone-based picking, equipment-based waves, one-at-a-time releases, and consolidated multi-order releases.

5. Why do warehouses prefer wave picking strategies?

Warehouses prefer wave picking strategies because it improves picking precision, reduces congestion, balances workloads, and provides better fulfillment visibility.

6. Can wave picking reduce warehouse bottlenecks?

Yes. Wave picking can reduce warehouse bottlenecks as waves control picker flow, preventing traffic jams and ensuring smooth warehouse operations.