What Is a Circular Supply Chain?

A circular supply chain focuses on the reuse, recycling, and recovery of resources throughout the entire production process. Unlike linear systems, it decreases the reliance on raw material and focuses on the long-run circulation of resources to limit environmental destruction and also guarantee sustainability.

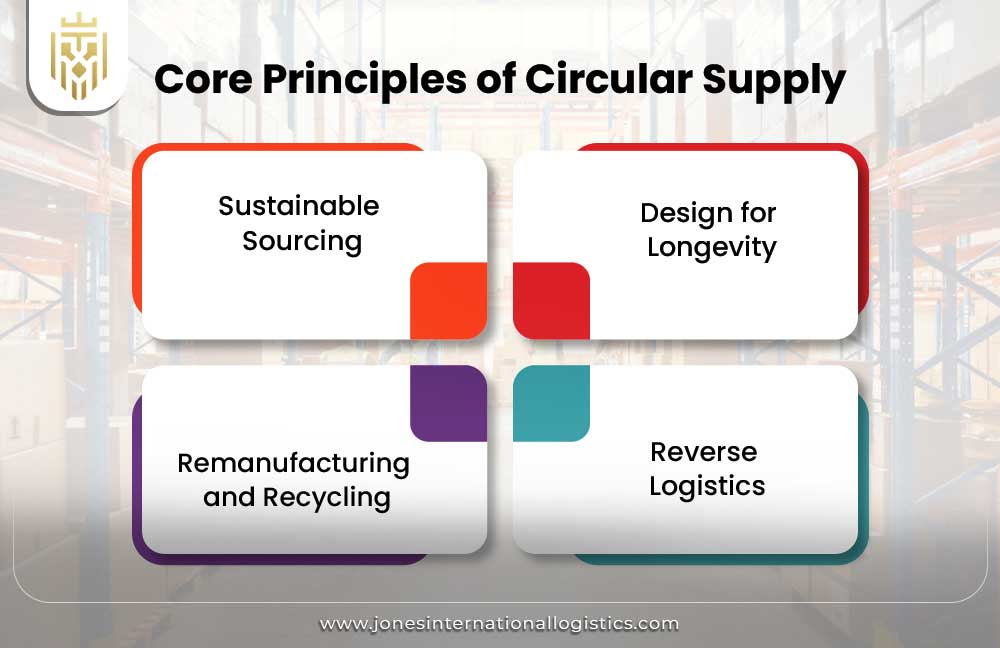

Core Principles of Circular Supply

The circular economy supply chain runs on the following principles: sustainable sourcing, design for longevity, reverse logistics, and remanufacturing and recycling. The principles advise industries to cut the reliance on virgin materials and move into regenerative as well as restorative design in supply chain management.

Sustainable Sourcing

Sustainable sourcing deals with obtaining materials that incur minimum ecological effects. Companies are focusing on utilising renewable, environmentally friendly inputs to minimise wastage together with long-term material availability and encouraging supply chain sustainability and ethical buying processes along the value chain.

Design for Longevity

Sustainable sourcing deals with obtaining materials that incur minimal ecological effects. Companies are focusing on utilising renewable, environmentally friendly inputs to minimise wastage, together with long-term material availability, and encouraging supply chain sustainability and an ethical buying process along the value chain.

Reverse Logistics

Reverse logistics is the stage where used products are returned for repair, retail, or recycling. Such a feedback loop facilitates a circular supply chain and reclaims materials or preserves the value of a product, which helps manufacturers reduce the environmental burden and widens customer interaction.

Remanufacturing and Recycling

Remanufacturing and recycling keep used materials out of landfills since they restore or continue using them. These activities are critical in the circular economy supply chain, as they minimise the consumption of raw materials and save resources that could be used in the future by industry and consumers.

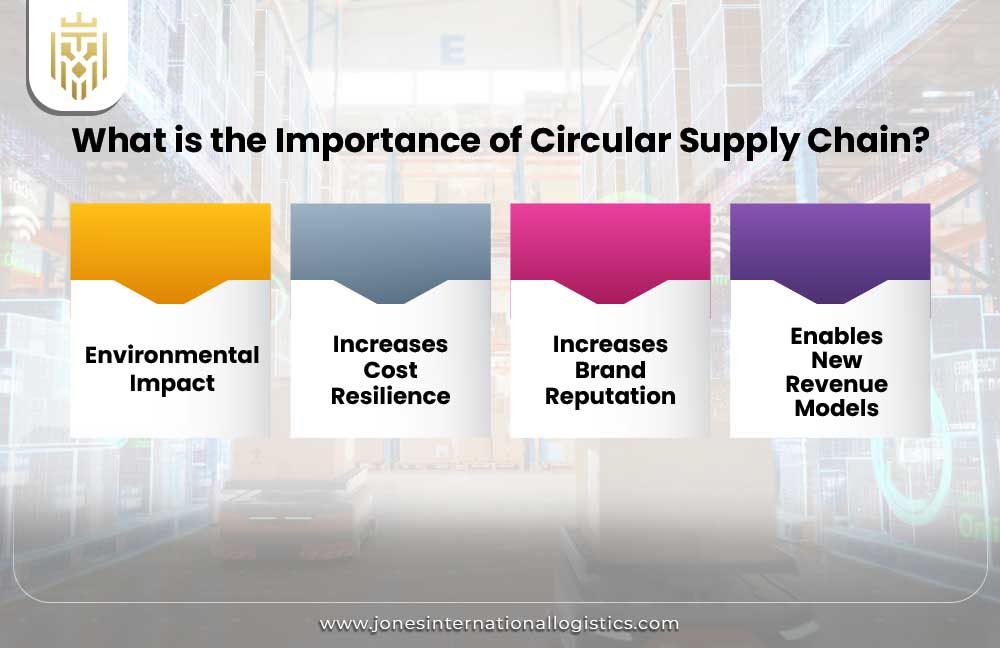

What is the Importance of Circular Supply Chains?

Circular supply chain models have significant importance as they offer lesser reliance on resources, improved environment, and sustainability of the economy. It assists the firms in readying themselves against the shortages of resources and regulatory changes in addition to encouraging sustainable supply chain management strategies.

Environmental Impact

Circular supply chains minimise pollution through the reduction of landfill use, consumption of energy, and resource extraction. These practices aid in maintaining ecosystems and biodiversity, in addition to enhancing corporate citizenship and quantifiable levels of attaining sustainability objectives in all industries.

Increases Cost Resilience

Circular supply chains enable businesses to have controlled costs through reusing material and avoiding reliance on the unstable raw market. This creates protection against points of failure in the supply chains and changes in prices and enables organisations to operate in riskier environments more efficiently.

Increases Brand Reputation

Adoption of a circular supply chain helps in improving brand reputation due to its integration with increasing consumer demand to purchase eco-friendly products. Businesses whose core value is sustainability can find positive trends in enhanced trust, positioning in the market, and customer loyalty.

Enables New Revenue Models

Rentals, product refurbishment, and product returns open new sources of revenue. These models derive the advantages of circular supply chain design, promoting repeat usage, minimising materials, and getting the maximum economic benefit of each product cycle.

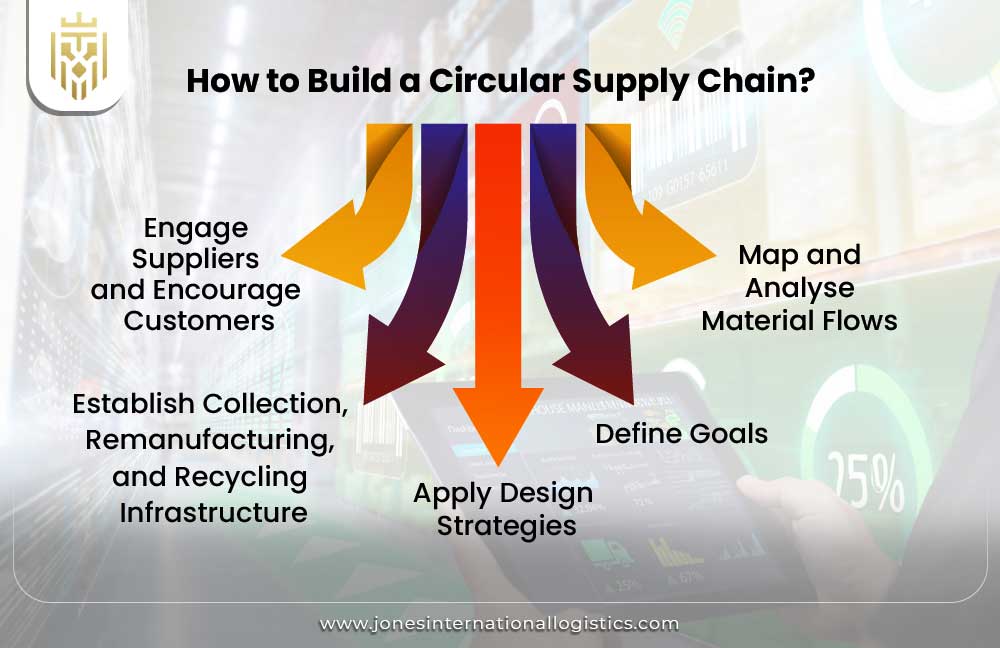

How to Build a Circular Supply Chain?

Organisations have to redesign processes, including sourcing and product disposal, to create a circular economy supply chain. This is inclusive of strategic design, reverse logistics, data-based analysis, and interaction with the stakeholders in all the sectors of the supply chain management system.

Map and Analyse Material Flows

The material flows are mapped to determine the places where waste is generated and can be recovered. It allows companies to identify areas where performance is inefficient and develop plans for more effective reuse, leading to an increase in the sustainability of supply chains and the operating efficiency of resources in the long term.

Define Goals

Setting measurable aims of circularity brings the stakeholders in line and allows them to track the improvement. Goals can revolve around a decrease in landfill waste, increased rates of recycling, or being able to design the way items can be used in the future—all with a bigger picture of sustainability in mind.

Apply Design Strategies

Companies should plan their products so that they are repairable, disposable, and recyclable. This foresighted design thinking can enable long-term use and material recovery as part of the main part of a successful round supply chain approach.

Establish Collection, Remanufacturing, and Recycling Infrastructure

Strong infrastructure is needed to reclaim used materials, segregate materials, and remanufacture parts. It is the core of the circular supply chains that render resource cycles viable/scalable within large and distributed product networks.

Engage Suppliers

Supplier cooperation provides upstream materials that are circular. Information exchange, alignment of incentives, and circular indicators in contracts will enhance supply chain management and create a strong basis for regenerative operations.

Encourage Customers

Bringing the customers into the circularity game by educating and incentivising them to take products back, reuse, or recycle enhances circularity. This involvement of the customer minimises waste and improves the efficiency and the environmental achievements of the supply chain as a whole.

Enabling Technologies

The most important factor in driving the circular economy supply chain is technology. A transparent and responsive system is established as digital tools are used to monitor product lifetime and maximise returns and use intelligent decision-making to recover resources.

Digital Product Passports

Digital product passports deliver the traceability of materials, enabling enterprises and consumers to know about the product origins, durability, and recyclability. The tools play an important role in handling complex circular flows and providing transparency in the sustainability of supply chains.

IoT and AI

Product usage and location tracking can be achieved in real-time with the help of IoT devices and AI analytics. These instruments also predict a cycle of returns, maximise utilisation of assets, and minimise inefficiencies so they can facilitate smarter closed-loop supply chain management circuits.

Blockchain

Blockchain can boost traceability by introducing a safe journal of the product flow, ownership, and lifecycle. It fosters trust amongst stakeholders and helps in accountability within the circular models, particularly in the context of complex circular supply chains.

Recycling and Remanufacturing Systems

Autorotting and remanufacturing support systems enhance sorting, dismantling, and material retrieval. Through the aforementioned, such innovations minimise costs of processing, do away with manual inefficiencies, and are the major contributors towards supply chain sustainability in contemporary industries.

Organisational and Ecosystem Adjustments

Businesses have to move functions internally and work externally to become fully circular in terms of the supply chain. Such alterations induce systems change and enable the expansion of circular practices to an entire ecosystem and product category.

Redesign Supply Networks

Supply network redesigning to be circular implies the introduction of reverse flows, regional loops, and return paths of products. This transition facilitates the reduction of emissions, the rise of resource recovery, and a new type of distributed supply chain management.

Collaborate with Suppliers and Partners

Value chain collaboration with suppliers and partners means aligned incentives and uniform circular practices. Exchanging the best practices, data, and innovations could be the way to address waste issues and create scalable and regenerative systems.

Track Circular KPIs

The use of circular KPIs to measure performance, such as material recapture rates or product reuse, allows companies to perform better in the long term. Such measures help leaders learn the rewards of circular supply chain activities and refine strategies.

Experiment with Product-as-a-Service and Leasing Models

Leasing models transfer value away from ownership to access. These groundbreaking models extend the number of items operating longer in the system and create automatic revenue, which fits the framework of circular supply chains and new customer demands.

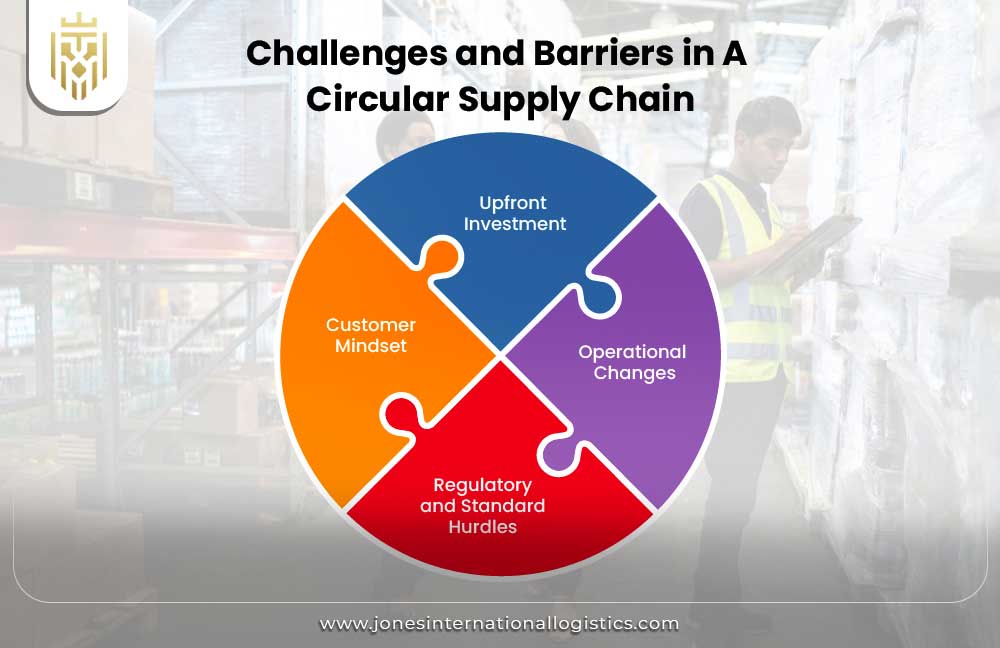

Challenges and Barriers

Although it is promising, the application of a circular supply chain can be a challenge, as it is expensive upfront and needs operational re-engineering, not to mention the cultural resistance. These obstacles are important to overcome in a bid to create more sustainability in the long term.

Upfront Investment

Developing circular capacities requires a lot of financial investments in technology, infrastructure, and education. Businesses will have to balance such pre-purchase expenditures with longevity, improved efficiency, and sustainability in their supply chains.

Operational Changes

The move to circularity means changing processes and teams and running new flows. They are new things that might create disturbance at the very beginning of operations but are inevitable in terms of the success of the cycle of supply chains in the long run.

Regulatory and Standard Hurdles

There may be hindrances brought about by regulatory uncertainty and the absence of circular standards. Policymakers and industry organisations need to work out structures to lead and promote the application of circular supply chains across a broad range.

Customer Mindset

It is time-consuming to switch customer behaviour from ownership to reuse or leasing. Communication and incentives should be provided clearly to motivate people to cooperate and be less resistant, as they may cause unnecessary production of waste.

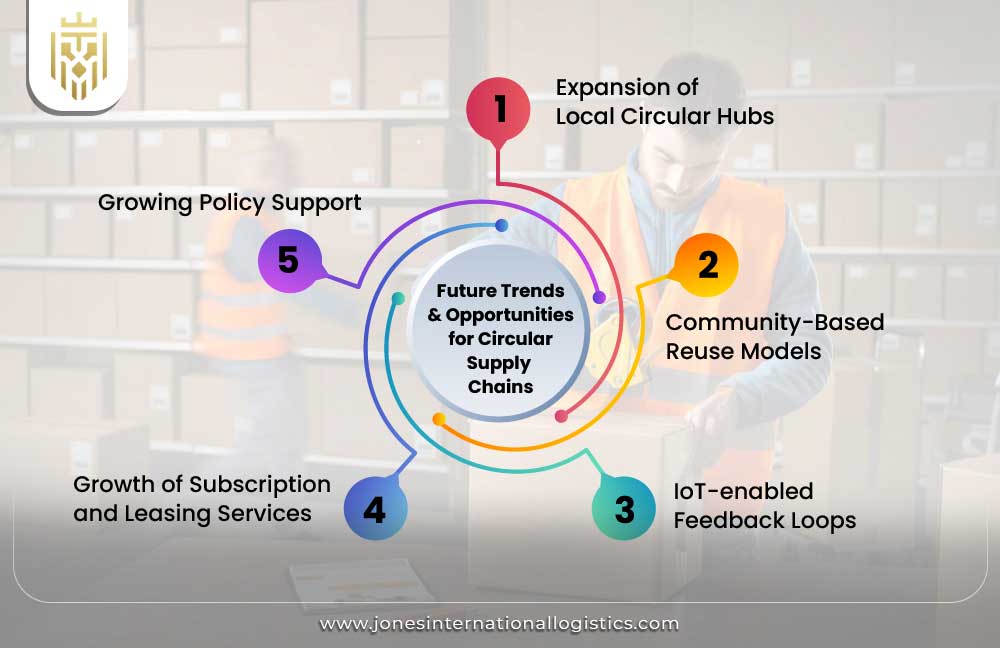

Future Trends & Opportunities

The new trends have shown that circular supply chains are likely to be more localised and data-driven as well as community-owned. The emerging trends will open the door to new economic, environmental, and social opportunities in sectors.

Expansion of Local Circular Hubs

Repair, recycling, and redistribution centres that are local and based are picking up. These decentralised facilities ensure fewer transportation emissions and more local employment, and they are fast-tracking the supply chain sustainability agenda.

Community-Based Reuse Models

Reuse programs have been community-based in the sense that goods are shared, and local repair can be done. Such models improve resource use and minimise wastage, particularly in underprivileged areas or areas of high consumption.

IoT-enabled Feedback Loops

IoT can build intelligent feedback systems, which monitor usage and points of return. This increases the circularity by creating a timely recovery, maximising the life span of assets, and streamlining the supply chain of the circular economy.

Growth of Subscription and Leasing Services

Leasing and subscriptions lead to fewer products being turned over and the reuse of products. The business models can generate recurrent revenue and match the consumer need for flexibility and sustainability and contribute to the future-ready circular supply chains.

Growing Policy Support

Most governments globally are encouraging circular models using incentives, rules, and sustainability obligations. Such increased support will coordinate practices, increase adoption rates, and maximise the advantages of implementing the circularity of the supply chain worldwide.

FAQs

1) How does a circular supply chain differ from a linear supply chain?

A circular supply chain focuses on the reuse and recycling of products rather than linear supply chains that use a take-make-dispose model, producing more waste and depleting natural resources.

2) Can small businesses implement circular supply chain practices?

Yes, it is possible to make small businesses embrace circular supply chain use of repair, reuse, local sourcing, and recycling groups to make their products less expensive to attain their products’ lifetime.

3) What metrics matter in circular supply chains?

Important indicators are the rate of material recovery, the life of products, their reuse rates, the carbon footprint minimisation, the sustainability of the supply chains, and KPIs like waste diversion and reverse logistics efficiency.

4) When does circular investment pay off?

Circular investment ideas are generally profitable in 3 to 5 years based on cost efficiency, reduction of waste, resource efficiency, brand value increase, and supply chain management resilience.

5) Which tech supports circular supply chain systems?

Technologies such as IoT, blockchain, AI, and digital product passports enhance the functioning of the circular supply chain, enhancing traceability, tracking of product usage, and reverse logistics.

6) What is a circular supply chain?

Circular supply chains involve the reuse, refurbishment, and recycling of materials throughout product life cycles to minimise waste and maximise sustainability.