What is Warehouse Layout?

Warehouse layout is the physical layout of a facility in terms of operations, equipment and storage that facilitates the unhindered flow of goods in operations in a warehouse. The design and layout of a warehouse should be well organized to ensure that it leads to productivity, lessening the handling time, and optimized material movement, which encourages effective order fulfilment and efficient logistics management as a whole.

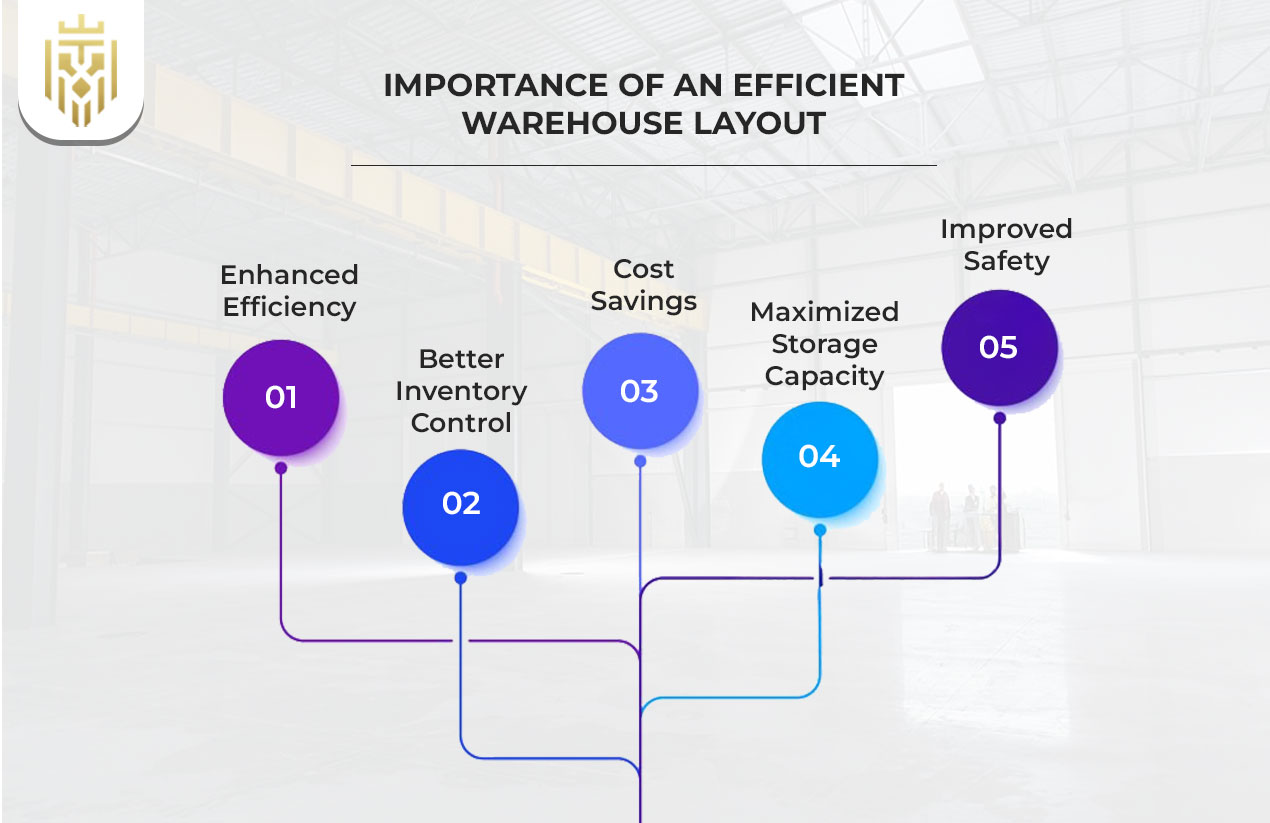

Importance of an Efficient Warehouse Layout

A good warehouse plan is essential in terms of maximising the space utilization, employee performance, and minimising the operational expenses. The strategic planning of warehouse layout also enables the business to enjoy smooth material handling, reduction of congestion and continuous flow of products, which eventually increases the overall performance and profitability of the warehouse.

Enhanced Efficiency

An effective warehouse layout plan increases efficiency by minimising the travel time and improves the coordination of the tasks. An optimised layout will allow the easy flow of the processes from receiving to dispatch, which will enhance accuracy and minimise idle time, which are directly linked to the productivity and quality of the services within the scope of warehouse operations.

Better Inventory Control

The optimisation of warehouse layout is beneficial in terms of the accuracy of tracking and inventory management in real time. The products’ turnover would help companies to align the storage layout so that they can access the products easily and reduce the picking errors as well as have a balanced inventory system to assist them in maintaining the accuracy of orders and efficiency in order replacement.

Cost Savings

The strategic warehouse layout strategy also plays a direct role in cost efficiency in reducing the material handling, labour hours and movement wastage. Efficient space management and material flow save on maintenance cost, equipment utilisation, and saving energy, and assists companies to keep lean operations and improve the profitability of the warehouse.

Maximized Storage Capacity

An effective warehouse layout design utilises both the floor and vertical space optimally. An effective racking system and storage system will provide a better use of the cubic space as well as organise the product placement so that more inventory can be carried out even though no expansion of the physical warehouse area is implemented.

Improved Safety

An efficient warehouse layout reduces the risks involved in operations. Using layout planning, the businesses are able to guarantee the safety in the flow of processes, the adequate space in aisles, and the ergonomics of workstations. This will allow it to avoid accidents and incidents that need adherence to safety standards and allow the staff to work in a safe environment.

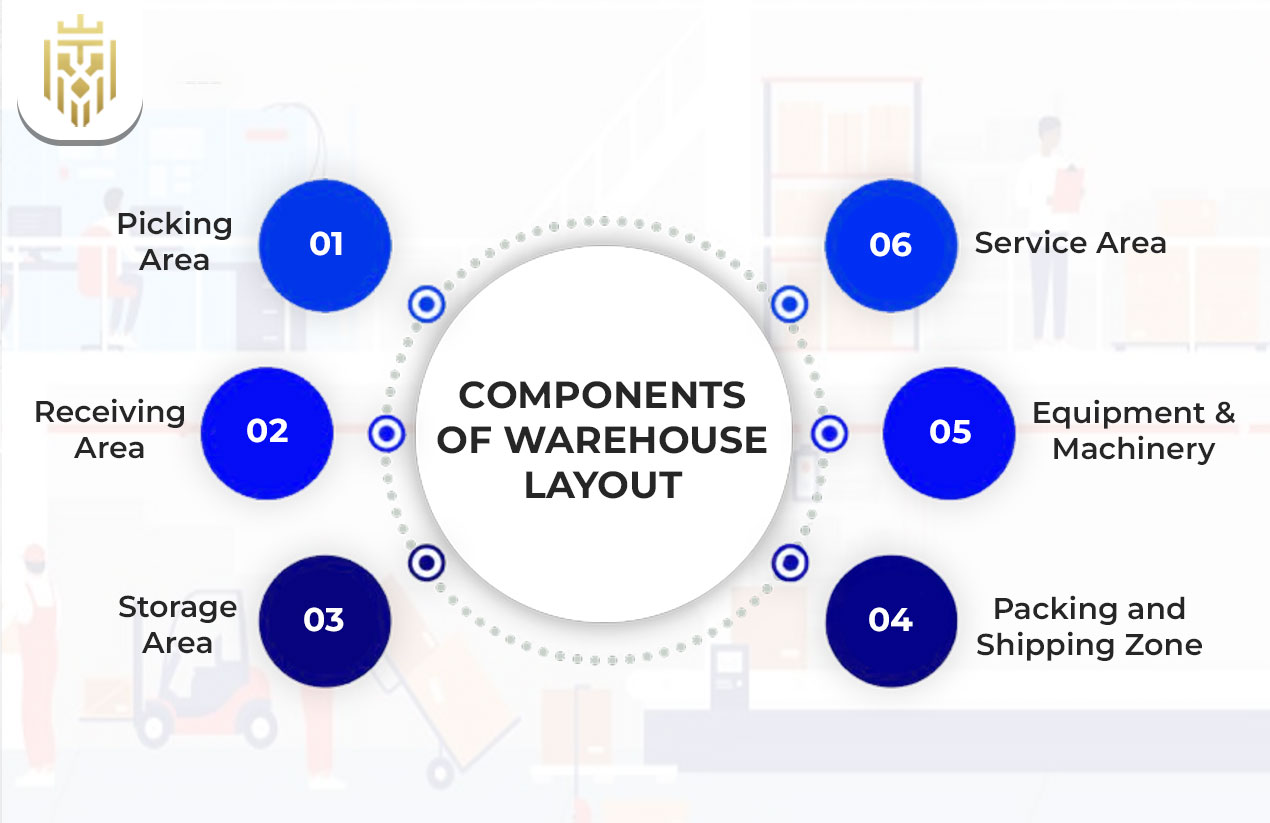

Components of Warehouse Layout

The main elements of any warehouse plan are reception, storage, picking, and packing areas. The efficient warehouse storage system and strategic space planning facilitate the transitions of the zones; therefore, they maintain continuous operations and accuracy of handling products and improve the performance of the whole warehouse.

Picking Area

The picking bay is intended to provide a fast item pick-up in order to make orders efficient. The correct product placement and layout optimisation minimise the movement distance and maximise the picking velocity, reducing the service times and operational process in high-demand settings.

Receiving Area

The receiving area manages the incoming consignments and quality inspection. A well-organised warehouse plan layout guarantees the efficient circulation of materials through the docks to the storage areas, facilitating proper verification, unloading and efficient processing of the incoming goods.

Storage Area

The storage space carries stock to distribute in the future. Capacity is optimised with the help of efficient storage layout and modern warehouse storage systems such as pallet racks or shelving. An effective logistics plan guarantees relief with effective and convenient storage facilities.

Packing and Shipping Zone

The packing and shipping area is vital towards order preparation to be delivered. This part reduces the delay in packaging and timely dispatching with the help of systematic layout planning and efficient warehouse layout efficiency, which facilitate the smooth outbound logistics activities.

Equipment & Machinery

The successful positioning of equipment and machinery helps in the smoothing out of the process flow in the warehouse. An effective design of the warehouse layout will provide forklifts, conveyors, and automation equipment with their own zones to meet safe transportation and maximum utilisation of the working space.

Service Area

The service area assists in maintenance, stocking and operations. By integrating it into the warehouse layout planning, this would enhance the efficiency of the warehouse layouts and allow the staff to undertake the maintenance and administration processes without interfering with the main warehouse operation and handling of materials.

Different Warehouse Layouts

The warehouse layout types cater to different operational objectives depending on the supply chain needs. From picking warehouse arrangements to consolidation centres, both designs maximise warehouse flow of goods so that space is used strategically to balance efficiency, accessibility and throughput.

Picking Warehouse

A picking warehouse concerns quick order preparation. These facilities make the process of order picking quicker through optimisation of warehouse layout and strategic placement of products and increase the accuracy of processing, which contribute to a higher level of customer satisfaction and operational throughput.

Production Warehouse

A production warehouse provides support to the manufacturing units in terms of storage of raw materials and components. The correct planning of the warehouse layout will facilitate the flow of materials, supply of material required by the production line on time, and the handling of the materials without causing the disruption of the production processes.

Distribution Warehouse

A distribution warehouse is one of the important logistics centres that are intended to dispatch in high volumes. It helps to facilitate the efficient movement of the material, rapid order processing, and timely distribution through the accurate warehouse layout optimisation and efficient usage of the available spaces. The layout improves speed of delivery, minimises transit time and improves overall performance of operations in the complex supply chains.

Transit Warehouse

A transit warehouse is a temporary storage of goods that circulate between the distribution points. The layout planning and the flow of processes will guarantee a rapid turnover and a small amount of idle stock. Through inclusion of the principles of warehouse layout design, visibility and minimisation of delays and facilitation of continuous logistics processes is increased especially within multi-modal transport systems which deal with time sensitive or perishable goods.

Consolidation Warehouse

The consolidation warehouse combines smaller consignments into a large one to streamline the goods flow within the warehouse activities. Using warehouse layout strategy and effective store systems, it keeps the transportation costs to the minimum, simplified dispatch and balanced usage of spaces with enhancement of faster outbound logistics to bulk distribution channel of both domestic and international networks.

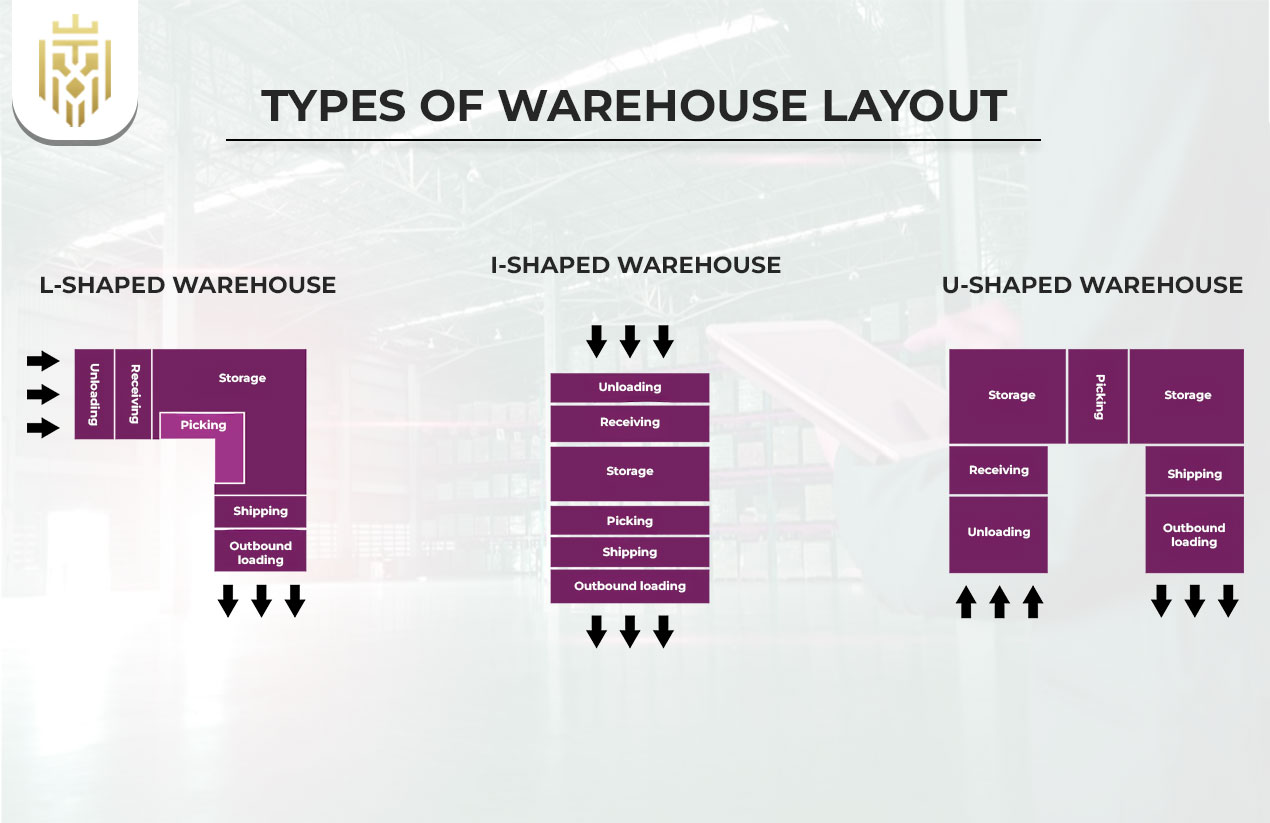

Types of Warehouse Design

Knowledge of warehouse design types assists individuals in identifying the most efficient workflow design. Planning warehouse layout and innovative warehouse design concepts will guarantee efficient material circulation, security, and availability. A flexible layout enhances the performance of the warehouse, long-term scalability, flexibility, and high throughput of various product types and operations.

L-Shaped

An L-shaped warehouse structure is appropriate when there is a need to have a separation in inbound and outbound locations in the operations. The layout plan of this warehouse design has ensured that there is a flow of processes, and there is less cross traffic, and efficiency is enhanced. It improves accuracy of the orders, organisation of the workflow, and clarity of the operations in high-volume and mixed-product settings using optimised racking systems.

I-Shaped

An L-shaped warehouse architecture facilitates a straight linear flow of materials in a receiving dispatch operation. The simple logistics plan improves the warehouse layout performance that reduces congestion and manages mistakes. This type of layout optimization allows continuous material flow, increased throughput, and efficient scheduling of the different sizes of operations, especially in automated or high speed facilities.

U-Shaped

The U-shaped warehouse scheme facilitates the smooth flow of the inbound and outbound processes with the help of the central picking place and the close storage space. The warehouse layout design provides support to tight movement and visibility as well as efficient space utilisation which would enhance accuracy of orders, minimise movement distance and increase efficiency in the warehouse working within a small or high-density space.

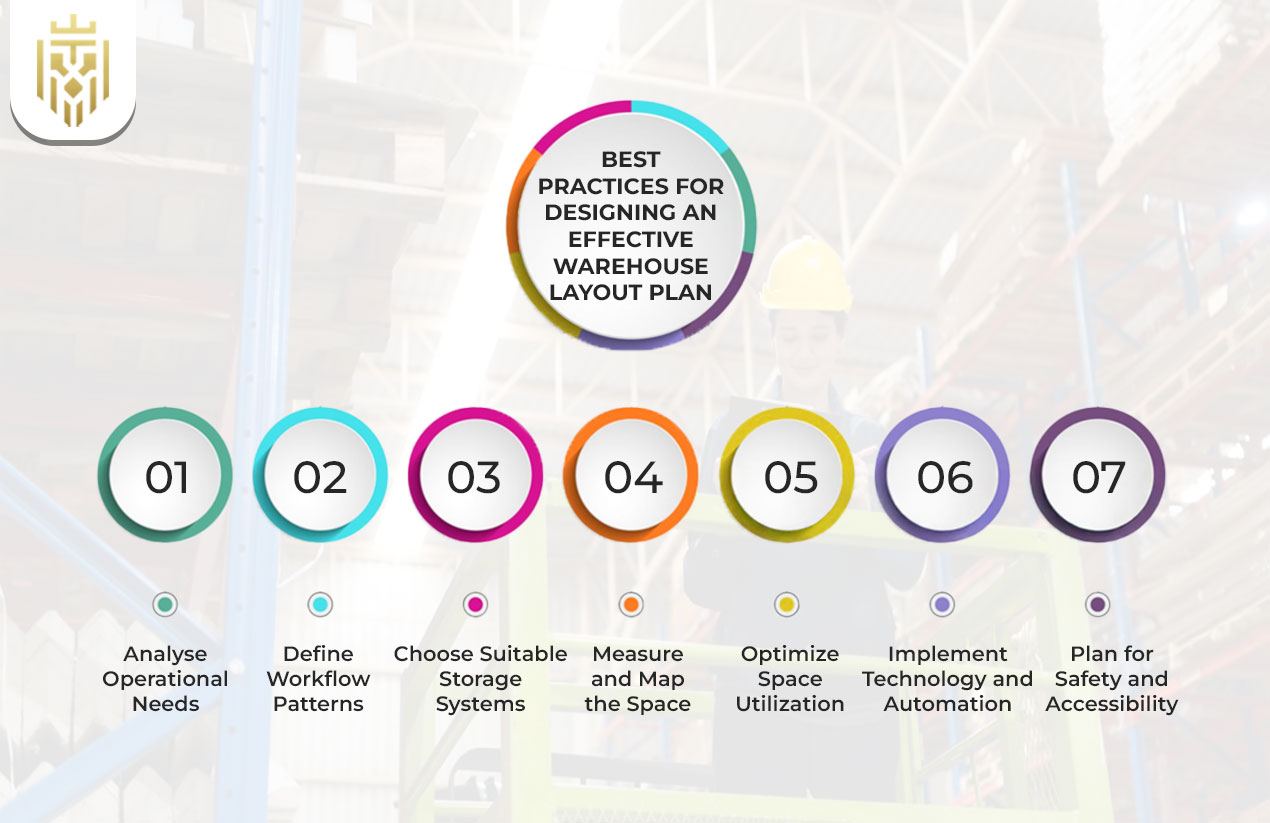

Best Practices for Designing an Effective Warehouse Layout Plan

To execute the appropriate warehouse layout plan, there is a need to balance between layout optimisation, space planning, and the integration of technology. The planning of strategic warehouse layout ensures that there will be an efficient flow of goods, improvement of the efficiency of warehouse layout, and continuous improvement in the scalable warehouse operations in accordance with logistics performance and future business development.

Analyse Operational Needs

Operational requirements play a critical role in the analysis that should be used to design a good warehouse layout design. Material flow and frequency of activity can be assessed to plan the layout correctly to have the optimal workstations, maximising efficiency and minimal movement. This measure creates a good basis towards productivity and equal logistical performance in the activities of the warehouse.

Define Workflow Patterns

Defining patterns of workflow facilitates rational flow of products between receiving and shipping. A well-defined warehouse layout plan increases the flow of processes and tasks. The incorporation of warehouse design concepts enhances visibility, reduces confusion, and enables an ordered pattern to the process of filling orders, which has a direct effect on warehouse efficiency and employee productivity.

Choose Suitable Storage Systems

Selection of suitable warehouse storage systems depending on the type of inventory leads to the best utilisation of space and maximisation of layout. Starting with the pallet racks to shelving units, all storage systems increase ease of access, minimise clutter, and improve safety of the warehouse, enabling efficient storage and durability of operation in case of an organisational growth of inventory demands.

Measure and Map the Space

Warehouse layout planning is based on accurate determination and mapping of floor areas. Knowing the space usage and the flow of goods within a warehouse can help to make decisions in the layout design that achieve harmony and help to fulfil efficient storage space, material movement, and sequence of workflow activities in warehouse settings that are fast-moving.

Optimize Space Utilization

The use of space is essential to optimise the capacity. With warehouse design optimisation and product positioning, the storage areas may be effectively organised to strike a balance between accessibility and inventory capacity. An effective layout enhances a better flow, less time in retrieval and high warehouse layout efficiency in all the departments.

Implement Technology and Automation

Incorporating automation in warehouse design increases accuracy and speed as well as flexibility. Recent warehouse design approach is to apply technology such as robotics and AI to streamline material circulation and picking rates and enhance real-time visibility, workflow regularity, and overall warehouse performance with intelligent systems and responsive automation structures.

Plan for Safety and Accessibility

The planning of the layout should focus on the safety and the accessibility for all personnel. The design and layout of the warehouse is well organised with clear aisles, emergency exits and ergonomic operations. Process flow makes the work environment safer and more welcoming to employees, and it also helps to keep the environment in accordance with occupational health and safety rules.

FAQs

1. What software can help create a warehouse layout plan?

AutoCAD, SmartDraw, and SketchUp software are used to develop warehouse layout plans to the point of detailing them, which optimises layout and provides space according to the flow of materials and allows a smooth running of operations to achieve optimal operational efficiency.

2. How do you calculate warehouse space utilization?

Divide total used space in the warehouse by total available space and then multiply that by 100. This evaluates the efficiency of warehouse layout and points out possible layout optimisation.

3. What are the main goals of warehouse layout optimization?

Top objectives of the warehouse layout optimisation include optimising use of space, enhancement of material flow, reduction in handling time, and warehouse efficiency, as well as ensuring automativeness between storage, picking, and shipping processes.

4. What are common space utilization techniques in warehouse design?

The approaches that are common in the utilisation of common space are vertical racking, ABC product placement, modular storage plans, optimisation of picking areas and planning the layout flexibly to enhance the flow of materials and overall productivity of the warehouse.

5. What is the best way to evaluate an existing warehouse layout?

Assess a warehouse design using space utilisation review, process time analysis, accuracy of inventory management and safety audit to maintain a balanced layout efficiency and progressive layout optimisation.