Understanding Backorders

When we are talking about backorders from the context of businesses, it often indicates a gap between demand and supply. In simple words, a backorder happens when a customer places an order for a product that is presently out of stock, but will be delivered once inventory is restored. For companies as well as customers, understanding the backorder meaning is essential, as it impacts expectations, reputations, and operational efficiency.

The Role of Backorders in Modern Supply Chains

In a modern supply chain, backorders play a two-fold role. On the one hand, they showcase the ongoing demand for a product even when supply is unavailable, which is a positive sign of market stretch. On the other hand, overwhelming backorders can burden logistics networks and crumble trust. Understanding what a backorder is and its role helps businesses strike a balance between customer satisfaction and operational limitations.

Customer Expectations in Backorder Scenarios

Customers always expect transparency and clarity in communication, especially in backorders. Failing to address their expectations with clarity can result in dissatisfaction and cancellations. Hence, companies must provide realistic timelines and routine updates to strengthen their commitment to extend beyond inventory constraints.

How Backorders Impact Business Reputation

Backorders can tremendously impact a business’s reputation, leading it to both positive and negative repercussions depending on how they are managed. For instance, repeated stockouts send a signal of poor management or inefficiency. And the same stockouts can be turned into positive reputation when handled correctly by giving transparent updates, compensation, or an alternative suggestion for the item. This can help in building trust among customers. In this digital era, business reputation is measured by how effectively backorders are managed.

What Triggers a Backorder?

Backorders can be triggered due to various reasons, including both internal and external factors. For better systems and reducing customers’ frustrations, identifying these triggers is very important.

Sudden Demand Spikes

Sudden demand spikes are one of the most common triggers of backorders. Promotional campaigns, seasonal shopping, or viral product trends can quickly dry out available stock. Without a buffer inventory, businesses are left processing backorders till stocks are restored.

Inventory Mismanagement

The next trigger is Inventory mismanagement of stock. Ineffective tracking systems, unreliable stock counts, or delayed restocking decisions can create artificial backorders. And businesses must be more careful about this, as customers don’t bother about technical or procedural errors, they only see the delivery delays.

Supplier Inconsistencies

Sometimes, backorders are also caused by suppliers, who fail to deliver orders on time. This can happen due to quantity limitations, shortage of raw material, or transport delays. These supply-side differences can directly affect businesses.

Production Bottlenecks

Production blockages can also lead to backorders. Machinery mishaps, shortage of labor, or quality control issues result in slowing down the production cycle, which will ultimately lead to backorders.

Forecasting Gaps

Inadequate demand forecasting creates an imbalance between inventory and real demand. If companies undervalue popularity or miscalculate buying patterns, this may lead to product shortages, which will lead to backorders.

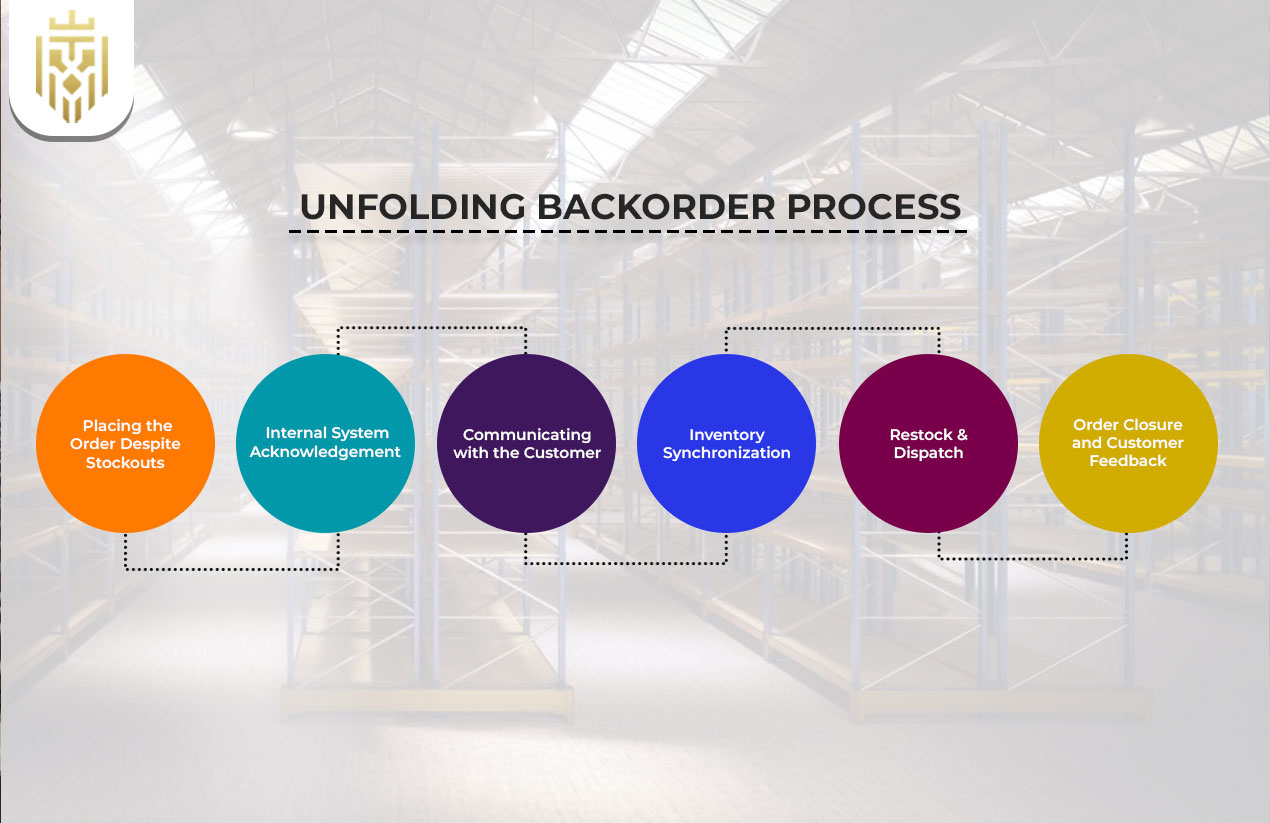

How the Backorder Process Unfolds

The backorder is a chain of processes that needs to be managed carefully. The process starts when a customer orders an item orders a product that is currently unavailable or out of stock. Instead of declining the order, the business accepts it as a backorder, updating the customer about the delay in the delivery time. After this, the next step is to monitor inventory, placing purchase orders with suppliers, and ultimately fulfilling the backorders once stock is restored.

Placing the Order Despite Stockouts

Even if the item is out of stock, customers can still place an order. In the system, this order will be considered as a backorder, assuring the customer about the delay in delivery time.

Internal System Acknowledgement

Once the order placement is done, the inventory system marks it as a backorder. Inventory management tools track all the pending orders and align them with the expected restock dates to ensure order fulfillment is done once the stock is restored.

Communicating with the Customer

Communicating with the customer is essential at this stage. Customers need to be notified about the backorder status, expected delivery time, and any potential alternatives. A well-informed customer is far more likely to wait patiently for the one left in the dark.

Inventory Synchronization

As stocks are replenished, businesses synchronize their inventory levels with the existing backorders first. This assures that the loyal customers who placed earlier orders receive their orders before processing new orders.

Restock & Dispatch

Once restocking is done, backorders are packed and dispatched as priority shipments. Smooth and updated handling at this stage can help in reducing customers’ frustration caused by earlier delays.

Order Closure and Customer Feedback

The last step in this process is closing the order and requesting the customer’s feedback. This feedback will help in improving the backorder process and strengthen trust for further purchases.

Common Challenges in Backorder Handling

Backorder management comes with a lot of challenges that require proper attention. Businesses may take backorders as a usual operation of the supply chain, but customers prefer it as a major problem in terms of service. These challenges do not extend fulfillment timelines but also affect overall brand image.

Delayed Fulfillment Cycles

The biggest challenge in backorder handling is the delay in fulfilling orders. Extended waiting times can easily frustrate customers and make it harder for businesses to maintain reliable delivery promises.

Increased Customer Complaints

With a delay in delivery comes complaints and bad reviews. During such cases, support teams often struggle with high call volume and email inquiries about backorder updates. When businesses fail to address complaints swiftly, the impact can extend beyond individual transactions, damaging long-term relationships with the customer and brand image.

Strain on Support Teams

Customer service agents face tremendous pressure during backorders. Constant updates, complaint resolution, and handling cancellations can strain teams unless dedicated communication is done.

Impact on Sales Forecasts

Repeated backorders may distort sales data, making it harder to forecast precisely. If demand is continuously unfulfilled, sales projections may appear weaker than actual market potential.

Negative Inventory Trends

Frequent backorders signal underlying inventory management issues. This will hamper operations and also affect financial health by indicating inefficiencies to stakeholders.

Strategies to Manage and Minimize Backorders

Minimizing backorders involves a blend of technology, supplier management, and customer-focused communication. Businesses implementing such strategies often find it easy to maintain customer loyalty and operational stability.

Strengthen Supplier Relationships

Building a strong, reliable relationship with the suppliers reduces the risk of disagreement. Coordinated planning and shared visibility into demand can help prevent backorder scenarios.

Use of Real-Time Inventory Tools

These days, businesses use real-time inventory tracking to safeguard accurate visibility. These tools restrict stock variation and support quicker restocking decisions, reducing backorders.

Automate Stock Alerts

Automation helps flag low-stock items before they run out completely. Early alerts allow procurement teams to act in time, avoiding unnecessary stockouts and backorders.

Refine Demand Forecasting Models

AI-based forecasting tools enable companies to predict demand more accurately. By improvising forecasts, businesses can control adequate stock levels and decrease backorder frequency.

Maintain Safety Stock Levels

Another strategy is to have calculated safety stocks as a backup to be prepared for sudden demand spikes, which will prevent having backorders. This works specifically well in industries with predictable peak seasons.

Transparent Customer Communication

Communication with the customers is very important. Maintaining transparency can impact positively even in backorder situations. Updating them about stock availability and backorder delivery will help in retaining customers’ trust.

How Backorders Affect Different Business Models

Backorders have a different impact in different industries. It differs depending on the type of business model, customer expectations, and the product lifecycle.

E-Commerce Retailers

In the e-commerce industry, backorders can ruin customer experience vastly. In such industries, customers expect instant availability, and delays may divert them to competitors unless such situations are handled properly and proactively.

B2B Product Distribution

In B2B, backorders can delay whole project timelines and production lines. Distributors must handle them carefully to eliminate straining long-term partnerships.

Seasonal & Limited-Time Sales

Backorders are mostly challenging in seasonal or limited-time campaigns. If customers miss out due to back orders, businesses lose their sales, which leads to risking long-term loyalty.

Subscription-Based Services

In subscription-based models, backorders impact the consistency of deliveries. Missed shipments can cause order cancellations and a decline in lifetime customer value.

FAQs

1. What does it mean when an item is on backorder?

When an item is on backorder, it means the product is out of stock but still available for purchase. Customers can still place orders, and items will get delivered once stock is restored.

2. What causes a product to go into backorder?

Products go into backorder due to demand spikes, forecasting errors, supplier issues, or production delays.

3. How long do backorders typically last?

Duration of Backorders varies depending on supplier timelines and restocking cycles. It ranges from a few days to several weeks.

4. How do companies manage frequent backorders?

Companies use forecasting tools, build strong supplier relationships, and maintain safety stock to minimize turmoils.

5. Can customers cancel a backordered item?

Yes, most businesses allow cancellations if customers don’t opt to wait for replenishment.

6. What’s the difference between backorders and pre-orders?

Pre-orders are placed for products not yet launched, while backorders are for existing products that are temporarily out of stock.

7. Are backorders a sign of poor inventory planning?

Not necessarily. While frequent backorders may indicate weak planning, occasional ones often reflect high demand and market popularity.