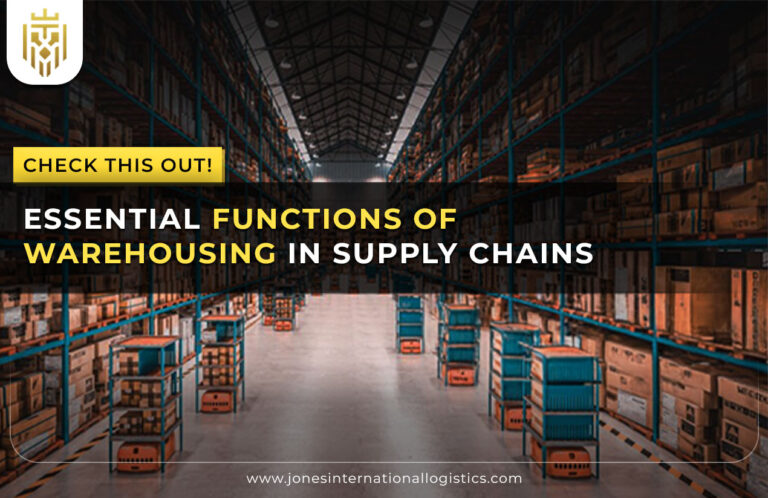

What is Supply Chain Management?

Supply chain management is the process of managing all activities that a product undergoes-including raw materials to delivery. Appropriate chain control will improve efficiency, save on expenses and provide customer satisfaction. To simplify supply chains, companies need to be familiar with different models.

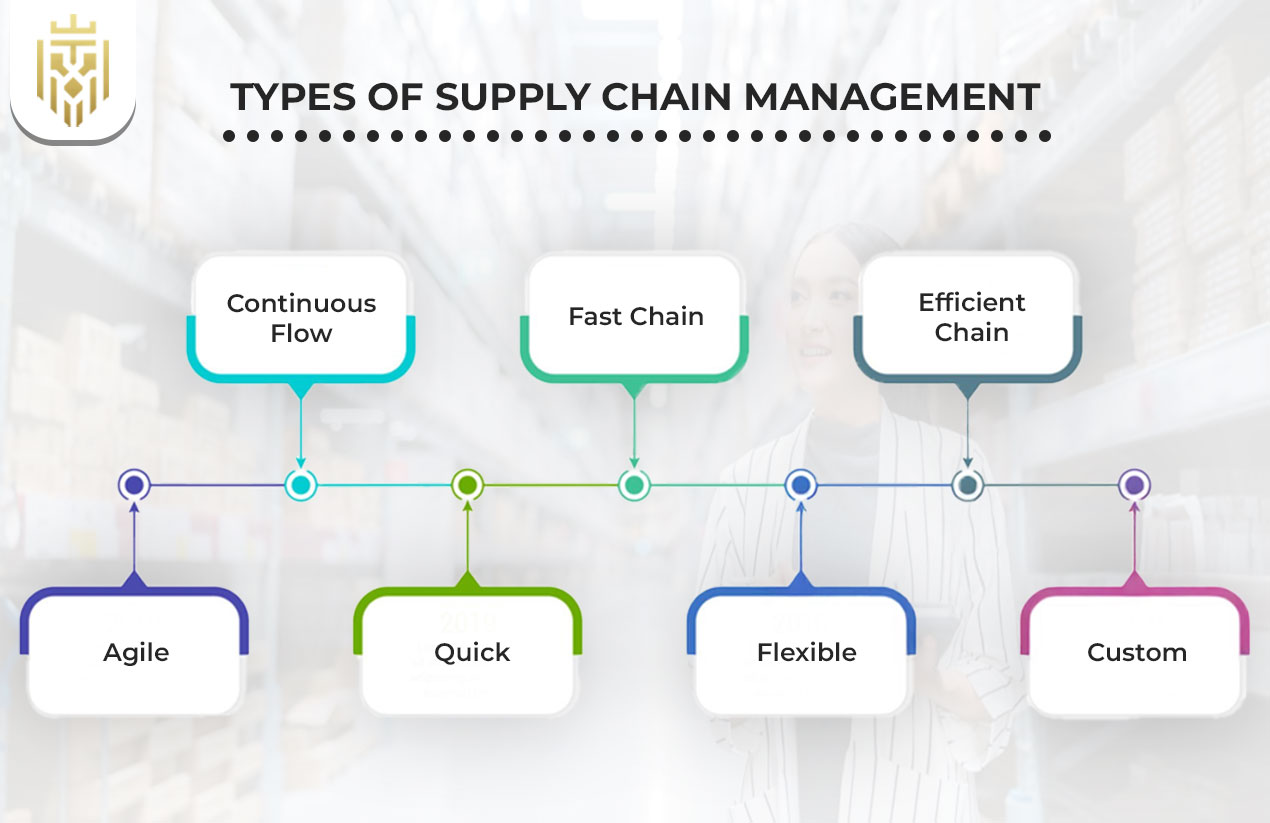

Types of Supply Chain Management

Supply chains have various management designs, which are Continuous Flow, Fast Chain, Efficient Chain, Agile, Quick, Flexible, and Custom. Businesses that want to be more efficient will have to learn about such models. When wondering how many types of supply chain management there are, it depends on needs and strategies.

Continuous Flow

Continuous Flow model is ideal in business whose production and demand are not unstable. This form of supply chain guarantees low risks and constant production. It allows predictability and thus it suits products whose variations change a few time intervals.

Fast Chain

The Fast Chain is optimum in the case of products having short life cycles. These supply chains change fast to maintain with trends and are fast and responsive. This model is increasingly used among many businesses to maintain their lead in the fast moving markets where customer tastes keep fluctuating.

Efficient Chain

The Efficient Chain model focuses on cost effectiveness and large-scale manufactures. It is among the forms of supply chain management techniques which touch on optimisation of the processes. Frequently, this lean and mean style entails benefits to businesses that produce stable, high demand products.

Agile

Agile supply chains are created to react quickly to the market changes and customer demands. The model is an essential tool of chain management in the areas of industry with an uncertain demand. It is characterized by the flexibility and responsiveness of the Agile supply chain model.

Quick

Quick model places more focus on speedy delivery and quick production. This is one of the various categories of models to train the supply chain, which makes a business shorten time lead and within a concise time, meet the demand of consumers. It is suited to the industries in which speed is the competitive advantage.

Flexible

The Flexible supply chain model gives business opportunities to alternate between various modes of production and distribution. This model is important to be learned by the companies that are working in the dynamic markets. It is flexible to counter the shocks and shifting consumer tastes.

Custom

The Custom supply chain model presents customised solutions given specific business demands. This is one of the specialised models in supply chains and features custom production and delivery procedures. It facilitates operations of companies that dictate high level of customised products and services.

Advantages of the Types of Supply Chain Management

By being aware of the benefits of the kind of supply chain management being adopted, companies can make the appropriate strategy. The number of types of supply chain management lets understand how to organize operations and improve efficiency of all the supply chains according to the needs of the market.

Advantages of the Continuous Flow

The Continuous Flow model offers regular product and makes planning easy. Such a type of supply chain will make the supply process more predictable and minimize any interruptions that affect production. Large established businesses that have a product line that is stable and does not have sudden variations tend to be in this line with stable reliability.

Advantages of the Fast Chain

The fast Chain model enables companies to be responsive towards the changing trends fast. It works very well when it comes to short lifecycle products. Compared to other models of the supply chain, this kind makes the supply chain relevant in the market due to speed that is essential in the competitive industry.

Advantages of the Efficient Chain

Efficient Chain method of doing things ensures that companies spend as little and produce as much. The model, which is one of the classes of supply chain management policies, simplifies workflow and this makes it suitable for those firms that want lean and high volume production.

Advantages of the Agile

Agile supply chain gives the flexibility to meet the market changes. It increases the capacity of a firm to match the changing demand, and benefits the industry that needs immediate reaction and creativity in its chain management.

Advantages of the Quick

Quick model enhances faster production and delivery, which gives the businesses a competitive advantage. Compared to the other forms of supply chains, the approach will shorten lead times and enhance the satisfaction of customers through allowing quicker availabilities of products.

Advantages of the Flexible

The Flexible supply chain modem enables organizations to handle the interruptions promptly. Companies operating in volatile markets are vital to be made aware of this benefit since it offers flexibility by use of flexible production and distribution systems.

Advantages of the Custom

Custom supply chain provides the custom solutions to the businesses having special product requirements. The model is high in personalisation and as such is preferred choice by most chain models in industries that have a clientele inclined towards customised goods and services.

Disadvantages of the Types of Supply Chain Management

As much as the types of supply chain management present numerous benefits, they possess disadvantages as well. That is why knowing about these limitations and having the answers to such a question like how many types of supply chain management exist are a way to reduce the risks of businesses and choose appropriate strategies to supply chains.

Disadvantages of the Continuous Flow

Continuous Flow model is not a flexible model and as such is inappropriate to businesses whose demand is fluctuating. Compared with other models of supply chain, this type can be exposed to difficulties in product variety or sudden market changes. Predictability is a good thing but may hamper flexibility.

Disadvantages of the Fast Chain

The Fast Chain strategy requires unceasing surveillance of the trends which may be costly to the operations. These supply chains can face difficulty in forecasting which could result into over-or under production of products in case there are mis-forecasts in the market demand.

Disadvantages of the Efficient Chain

Efficient Chain model trades off flexibility in favour of efficiency. Such trade-offs can be a problem when there is an abrupt change in demand patterns. as much as it is among the varieties of supply chain management strategies, it might not be applicable in case of unpredictable markets.

Disadvantages of the Agile

The Agile supply chain becomes a heavy investment involving numerous technology and training. Even though it enhances responsiveness, it also expands the level of complexity in operation in chain management, hence not accommodated especially by small commercial entities that have limited resources.

Disadvantages of the Quick

The Quick model is based on speed and at times it is at the cost of quality. This source of supply chain, among the various forms of supply chain, could result in increased error quotient or a hurried up manufacturing process that influences the reliability of a product and its brand.

Disadvantages of the Flexible

The Flexible supply chain demands extensive costs of resources, and a change in production always. Learning about this challenge is crucial to know why businesses looking into this model should be aware of the high-frequency changes since these may increase costs and make the operations more cumbersome.

Disadvantages of the Custom

The Custom supply chain model may be costly and difficult to handle. Although there is intense personalisation in this type of the chain model, it will take extensive investment in sophisticated processes and will thus not be applicable in mass production oriented cases.

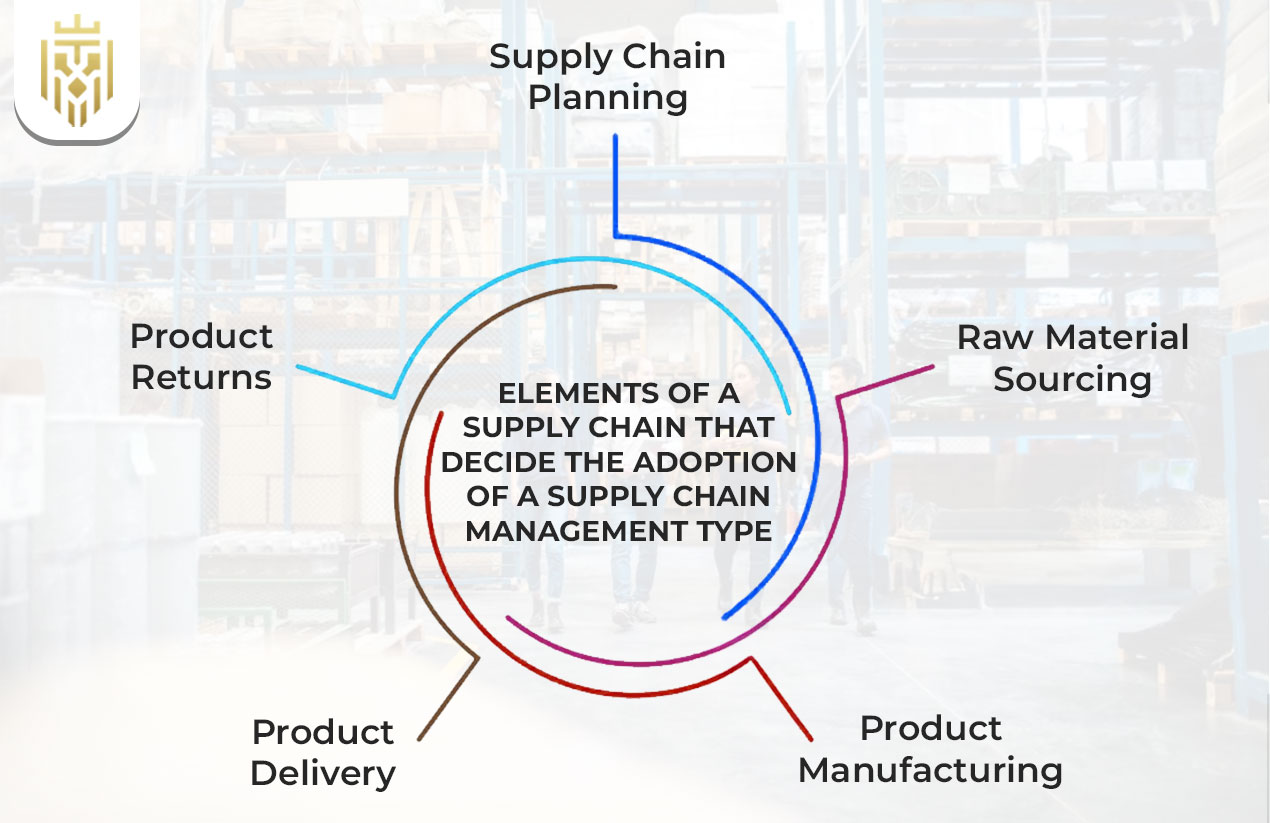

Elements of a Supply Chain that decide the Adoption of a Supply Chain Management Type

Indications of vital components in a supply chain such as planning, sourcing, and delivery of the products determine the category a supply chain management to be applied by the business. The knowledge on these factors promotes the companies to choose the appropriate supply chain models to succeed in their operations.

Supply Chain Planning

Chain management lies on the supply chain planning which defines the best models of supply chains to be embraced. What is so important to study is the stage of the planning so to adopt the right decisions to accomplish the action in the right way.

Raw Material Sourcing

The availability of raw materials influences the decision made in the planning of the supply chain and determines which chain models are the most effective. Various sourcing strategies are to be learned by businesses, in order to fit the kind of supply chain management that best suits them in their operations.

Product Manufacturing

Product manufacturing is one of the important processes in supply chains. The firms should realize the number of forms of supply chain management to embrace the most appropriate supply chain models to facilitate easy production and inventory balance.

Product Delivery

The delivery of products is critical in the chain management and is based on the various kinds of the supply chain models. In efforts to streamline delivery operations, business should be familiar to the ideal practices of making deliveries in consonance with the adopted supply chain management model.

Product Returns

In supply chain management, the methodologies of managing the product returns involve assessments of the type of supply chain management strategies to reduce disruptions. Organisations should also be taught about the handling of returns so that the process of chain management remains effective and customer oriented.

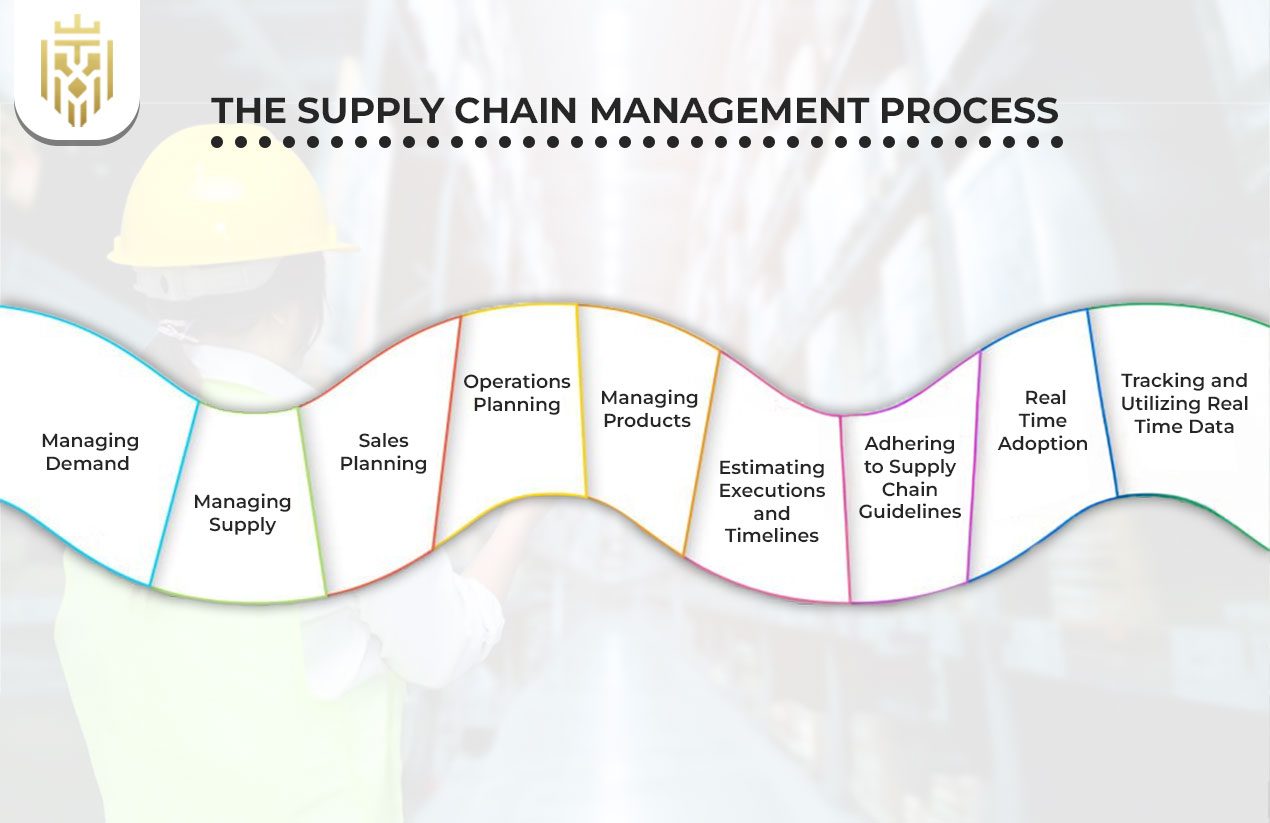

The Supply Chain Management Process

The chain of management of the supply includes the process of planning, sourcing, operations, and the movement of products. In order to conduct successful chain management, business needs to educate itself about various kinds of processes that correlate with their distinct chains of supply and market requirements.

Managing Demand

Effective demand management is the key measure in supply chain management. Businesses ought to familiarise themselves with the kinds of supply chain management strategies to strike a balance in inventory as well as ensure that the chain management is responsive to the consumer demands in any type of market.

Managing Supply

Supply chain management is an essential part of supply chains that call for the appropriate models of supply chains. The companies ought to be aware of the number of types of supply chain management to implement viable strategies to facilitate timely execution of the supply chain.

Sales Planning

Sales planning is a key chain management component that helps to conduct appropriate forecasting in chain supply. One should know the different kinds of supply chain management, which are available and will lead to increased sales in synchronisation and better execution of performance.

Operations Planning

All chain models that are involved in supply chain management are linked using efficient operations planning. Firms ought to acquire the knowledge on how proper planning enables successful supply chain management strategies to complement resources, minimise wastage and satisfy demands always.

Managing Products

In terms of supply chains, management of products involves businesses acquiring knowledge of the proper supply chains. Deciding on the various types offered guarantees the flexibility of the chain and the ability to facilitate proper inventory movement in all the processes.

Estimating Executions and Timelines

Exact time line estimation enhances the process of chain management which relates to the particular models of supply chain processes. The number of types of supply chain management should be investigated to choose the suitable approach in every situation of work.

Adhering to Supply Chain Guidelines

The operation of the chain in supply chain management has to follow guidelines in order to have a smooth process of chain management. It is important to have an insight into various kinds of rules and processes involved in the types of supply chain management to achieve compliance and efficiency in operations.

Real-Time Adoption

New strategies are crucial to adopt in real time in supply chains. The business enterprises ought to receive information about the advantages of incorporating the forms of supply chain management strategies in order to enable the businesses to be agile and rapidly adapt to the situations that change in the market.

Tracking and Utilising Real-Time Data

Chain management tracking of real-time data is crucial in supply chain systems. Businesses need to know the number of types of supply chain management available so that they can realize the usefulness of data in making improved decisions in supply chains.

Supply Chain Management Difficulties and Challenges

Long completion time, an unpredictable event, and increased costs are some of the challenges experienced in supply chains. To beat these challenges, companies ought to study the number of supply chain management types available to help you adopt the appropriate chain management tool.

Longer Implementation Time

Incorporation of the supply chain management is usually time consuming. Being aware of the various supply chain models can assist a business to overcome these delays. One has to get to know of effective ways that do not require a lot of set up time and can enable deployment to be made faster.

Ever-Changing Consumer Needs

The requirements of consumers are dynamic; they are swift and they require the supply chains to maintain. Firms must get to know the nature of the supply chain management strategies that provide flexibility so that they too can be in a position to change easily and be able to sustain their competitiveness in the chain management department.

Long Completion Chain

In chain management, a long completion chain makes supply of an operation difficult. Knowing the answer to the question: how many types of supply chain management are there makes companies choose the strategies that minimize the time of completion and optimize the supply chain models so that delivery becomes faster.

Natural Adversities

Supply chains can be interrupted by natural misfortunes. The firms ought to get to know about what forms of supply chain management are capable of absorbing such shocks. The resilience acquisition of chain models will enable the existence of supply chains amidst unfavourable obstacles in the environment or even globally.

Unpredictable Circumstances

Chain management is complicated by unpredictable situations. Businesses can anticipate uncertainty through choices of the appropriate supply chain models. Getting to know about other management strategies makes the companies react early to any disturbance in the supply chain.

Increases in Cost

One of the major problems in supply chain management is cost increase. The firms have to consider the number of varieties of supply chain management exists to choose cost-efficient chain models that can allow them to regulate the expenses used in the supply chains without compromising the quality of the services offered by the supply chains.

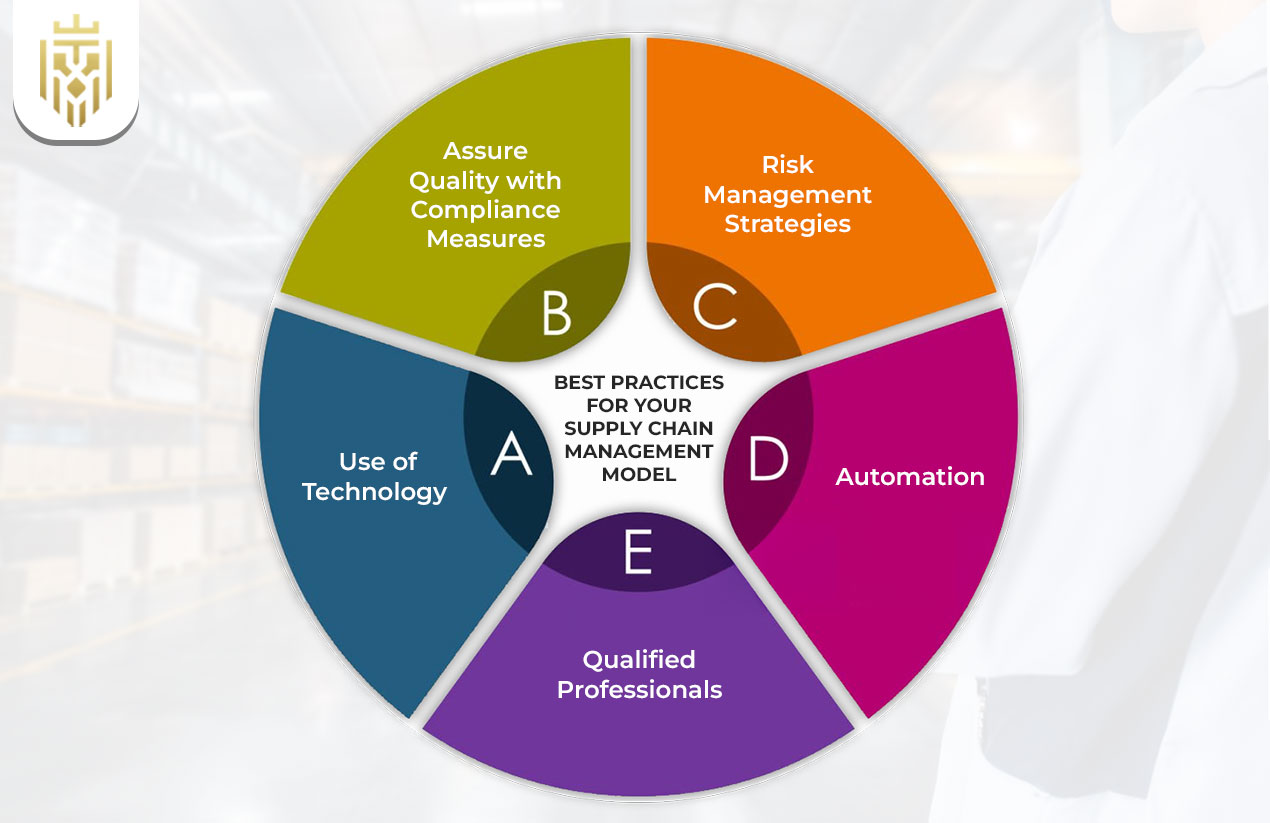

Best Practices for Your Supply Chain Management Model

Best practices in supply chain management include the use of technology, automation and management of risk. Learning more about the types of supply chain management strategies makes sure that types of chain involved in the business are chosen that are appropriate to encourage efficiency and supply chain resilience.

Use of Technology

Technology helps reinforce chain management and streamlines the supply chains. Firms ought to know the categories of supply chain management tactics that incorporate technology in order to enhance efficiency, real-time monitoring as well as the overall visibility of the chain of supply.

Assure Quality with Compliance Measures

Supply chain management is an area that needs to be handled under strict quality assurance. Familiarizing with various forms of quality tests and the usage of supply chain models will guarantee the smooth running of the chain and compliance with regulatory requirements at the end of the product life.

Risk Management Strategies

The aspect of risk management is important in chain management. To choose the supply chain models, companies have to know how many types of supply chain management are there in order to reduce the risks that are likely to be experienced and still achieve supply chain agility and the ability to withstand the changing market.

Automation

The use of automation within the supply chains increases speed and precision. Companies ought to be informed of the various forms of supply chain management to maximize automation seeking to streamline services, minimise inaccuracies and sustainable chain management through out all activities.

Qualified Professionals

To handle the chain effectively, it is important to hire experienced personnel. It is important to know the number of varieties of supply chain management exist to enable businesses to know about the expertise required to deal with complicated supply chain models effectively and sustainably.

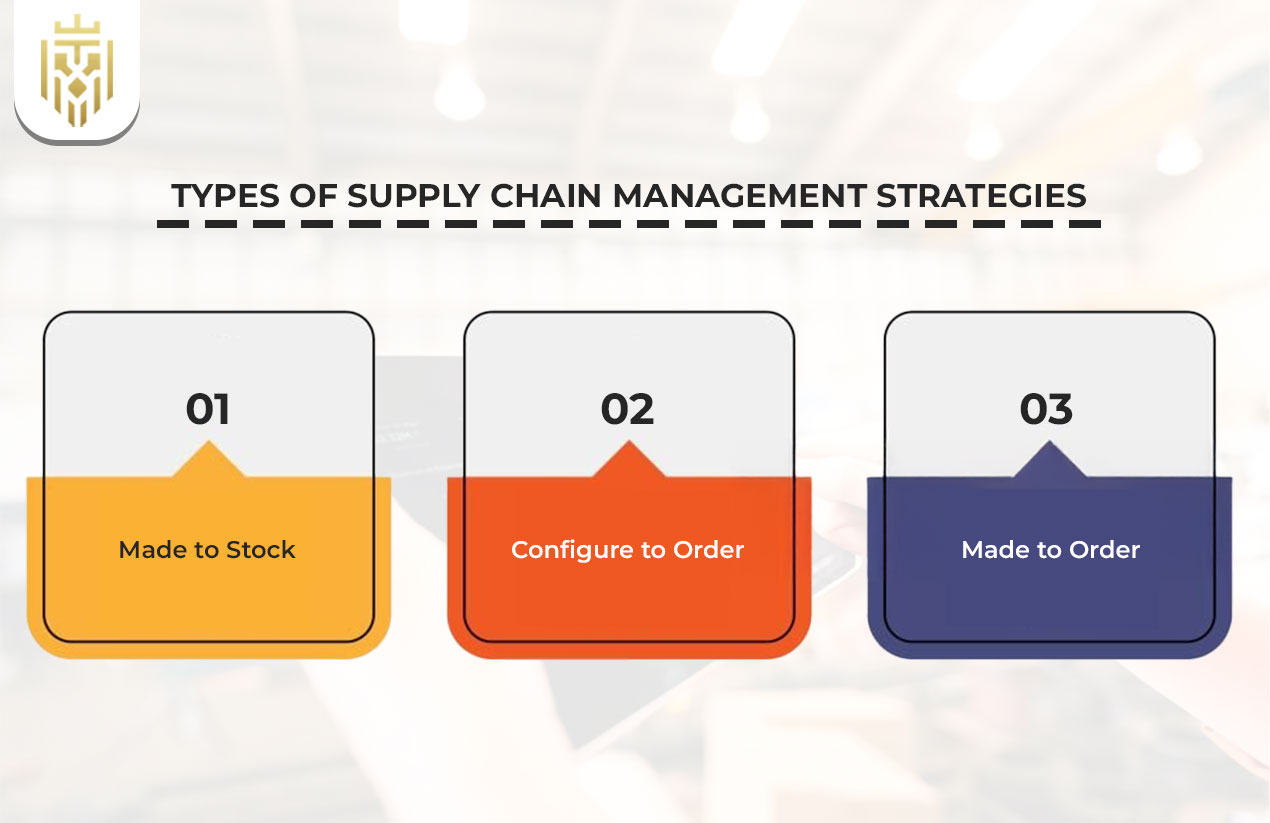

Types of Supply Chain Management Strategies

Supply chains strategies such as Made to Stock, Configure to Order and Made to Order are types which assist companies to manage different markets. To streamline procedures and to improve the management of the chains, business entities are encouraged to study such different types.

Made to Stock

Made to Stock is a well-known supply chain strategy. One should be aware of this method as being one of the types of supply chain management strategies since it is oriented on the production of goods ahead of time according to the forecasts made.

Configure to Order

One of the alternative types of supply chain models is the Configure to Order that is a reasonable compromise between efficiency and effectiveness. The companies ought to get to know of this flexible alternative under the form of supply chain management strategies which can be used to satisfy the specific needs of a customer.

Made to Order

Made to Order embraces high levels of customization of supply chains. Knowing the number of types of supply chain management there are can assist business people in realising the importance of this model. It would be suitable in those industries where the concept of mass production in chain management is not paramount.

Conclusion

In order to have an idea of supply chain management, it is important to be aware of the different kinds of supply chain management strategies and the ways that they would be appropriate to your operations. Knowledge of the number of types of supply chain management will allow you to feel free to adopt the appropriate chain models.

FAQs

1) What are the 7 types of supply chain management?

The 7 types of supply chain management are Continuous Flow, Fast Chain, Efficient Chain, Agile, Quick, Flexible, and Custom. These different types help businesses optimize supply chain models based on unique operational needs.

2) What are the types of supply chain management?

The common types of supply chain management include Continuous Flow, Agile, Efficient Chain, Quick, Fast Chain, Flexible, and Custom. These supply chains ensure businesses meet varying market demands using suitable chain management strategies.

3) What are the key elements of a supply chain management process?

The supply chain management process involves managing demand, supply, operations, products, and timelines. These key elements of a supply chain work together to build efficient supply chain models that boost productivity and streamline chain management.

4) What are the best practices for supply chain management?

Best practices for supply chain management include technology use, automation, qualified professionals, and risk management. These methods help optimize supply chains and align operations with the most effective types of supply chain management strategies available.