What is the Meaning of Transloading?

Transloading is a logistics process by which materials are transferred into another mode of transportation during their journey. It benefits shippers by reducing expenses, avoiding delays, or ensuring the efficient delivery of goods to their destinations-mostly in international and multimodal supply chains. When a certain route may simply not exist, or even be available but too time-consuming, transloading can be a way to ensure a continuous flow of cargo. Essentially, with the flexibility that transloading offers, businesses can respond to market forces and solve their logistics problems more easily.

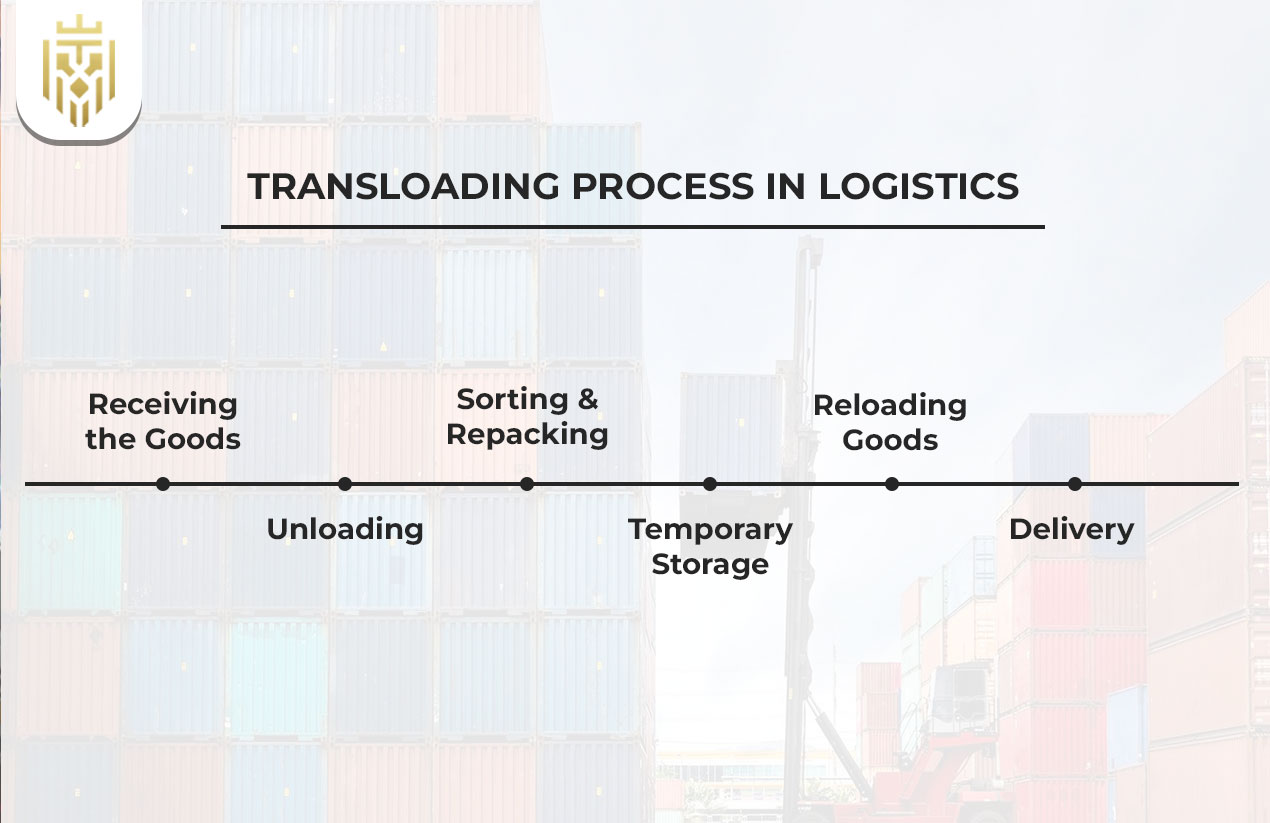

Transloading Process in Logistics

The transloading process is a series of steps that ensure smooth cargo transfer from one transport mode to another. Each stage plays a vital role in maintaining efficiency and product safety.

Receiving the Goods

Proper documentation starts with receiving the cargo at the transloading facility from the initial mode of transport. Here, cargo is checked, verified, and discrepancies, if any, are recorded prior to further handling.

Unloading

Next is unloading the cargo carefully onto equipment such as a forklift or crane, depending on the nature of the goods. Proper unloading avoids damage to the product and sets the way clear for the next steps.

Sorting & Repacking

Goods may be sorted, consolidated, or repacked into other sizes and forms for final distribution purposes. Such a step enhances the flexibility of a small business allowing it to customize shipments to multiple destinations.

Temporary Storage

Sometimes goods may require temporary storage until being shipped once again. Transloading provides secure warehouse options, keeping the products safe during interim storage.

Reloading Goods

Cargo is reloaded onto the next mode of transport, such as trucks, trains, or ships, depending on delivery routes. Careful handling ensures the safety and integrity of goods at this crucial stage.

Delivery

The process ends with final delivery to the intended destination. By combining multiple modes, transloading helps businesses achieve faster, more cost-effective, and reliable delivery solutions.

Transloading Costs

While transloading offers many advantages, it also comes with costs that businesses must account for. These expenses vary depending on labour, distance, type of goods, warehousing, and customs requirements.

Labor & Handling

Including the unloading, repacking, and reloading of goods, proper handling of goods demands skillful labour. The labour cost can be substantial; however, it warrants the right handling of goods and increases the assurance that the risk of damage to these goods is minimal. Trained workers being on the job will facilitate and, thus, reduce expensive delays.

Distance & Routing

The placement of transloading facilities affects costs. Transloading facilities that are strategically located near ports or rail heads reduce costs and improve efficiency. In contrast, a bad planning of a route is weighty on fuel consumption and increases delivery time.

Type of Goods

Each product will incur different costs according to its handling needs. Fragile, hazardous, or oversized goods require extra caution, which adds to expenses compared to general cargo. More packaging or safety gear may also mean higher costs in such cases.

Warehousing

Temporary storage may be required when cargo is at the mercy of another transport mode. Given that extended warehousing adds to the cost, careful planning is therefore necessary. Superlative inventory control systems could cut down storage times unnecessarily and save costs.

Customs & Compliance

International shipments often require customs clearance, inspections, and tariffs. Compliance costs are unavoidable but essential to avoid delays, fines, or disruptions in trade. Partnering with experienced customs brokers can help streamline this process and keep costs under control.

Benefits of Transloading

Transloading provides businesses with several advantages that strengthen supply chain efficiency and reduce costs. It also enhances flexibility, supports last-mile delivery, and contributes to sustainability.

Improved Supply Chain Efficiency

Through seamless movement of goods across different transport modes, any bottlenecks to the supply chain are minimized, thereby maximizing efficiency in timely deliveries and smooth logistics operations. Moreover, seasonality in demand is bypassed, so goods can be sent to areas where they are most required at any time. Eventually, this would price in agility towards transloading, a merit of the supply chain.

Reduced Costs

Optimized routing and a fuller utilization of containers lead to less general shipping expenses. Also, businesses save by not having to deal with empty returns or extra storage. Fewer handling also means less damage, which translates into less cost from replacement and insurance. Savings from these areas can then be reallocated toward other segments of the business operation.

Distribution Flexibility

Goods can be redirected to several destinations from transloading hubs. Companies can rapidly respond to ever-shifting demands from customers. Retailers can fill their stores faster, while manufacturers adapt to sudden changes in raw material needs-and that flexibility is highly essential in today’s fast-paced, consumer-driven world.

Last-Mile Delivery Support

Transloading allows last-mile delivery to speed up and pay less to be completed. It allows companies to reach areas from other markets, such as Tier 2 and Tier 3 cities. This ability to do so adequately builds customer satisfaction through reduced delivery time and wider service area coverage. Hence, these organizations acquire much better standing in the market by having wider geographies to cover.

Speed & Reliability

Since the goods move to their final destination by combined transport modes, they get faster. Such developments give fill extinguish in the disorganization of the customer and build up supply chain strength. This reliability can provide predictable delivery scheduling to retailers, distributors, and consumers. Due to which, the delays and disruptions less so occur in businesses.

Reduced Green House Gases

Efficient planning avoids unnecessary trips, fuel consumption, and emissions. Transloading helps promote greener logistics and green corporate sustainability goals. Organizations practicing this method would be in good standing regarding government regulations concerning emissions and green practices. Furthermore, they must maintain this green logistics approach, thereby enhancing their brand image among the consumers.

Transloading vs Other Shipping Methods

Understanding the difference between transloading and other shipping methods helps businesses select the right strategy. While transloading focuses on flexibility and multimodal transfers, other methods have distinct features and use cases.

Transloading

Involves transfer of goods from one mode of transportation to another to optimise cost and delivery time. It is mostly used for long-distance or international supply chains. In transloading, extra flexibility in repackaging and sorting the goods is provided to the distributors.

Cross Docking

Goods are unloaded to be washed and unloaded again. It speeds up a supply chain but at the cost of flexibility, which is more offered in transloading. It is best used in fast-moving consumer goods that are speed-oriented more than customisation.

Intermodal Shipping

The containers remain sealed and are moved across multiple modes without unpacking. It minimises handling but does not allow sorting or repacking like transloading. This method is most efficient for bulk goods that require minimal handling and maximum security.

Transshipping

Goods are transferred between vessels at ports during international trade. This method is common in ocean freight but limited to maritime routes. It often supports global trade lanes where direct shipping connections are not available.

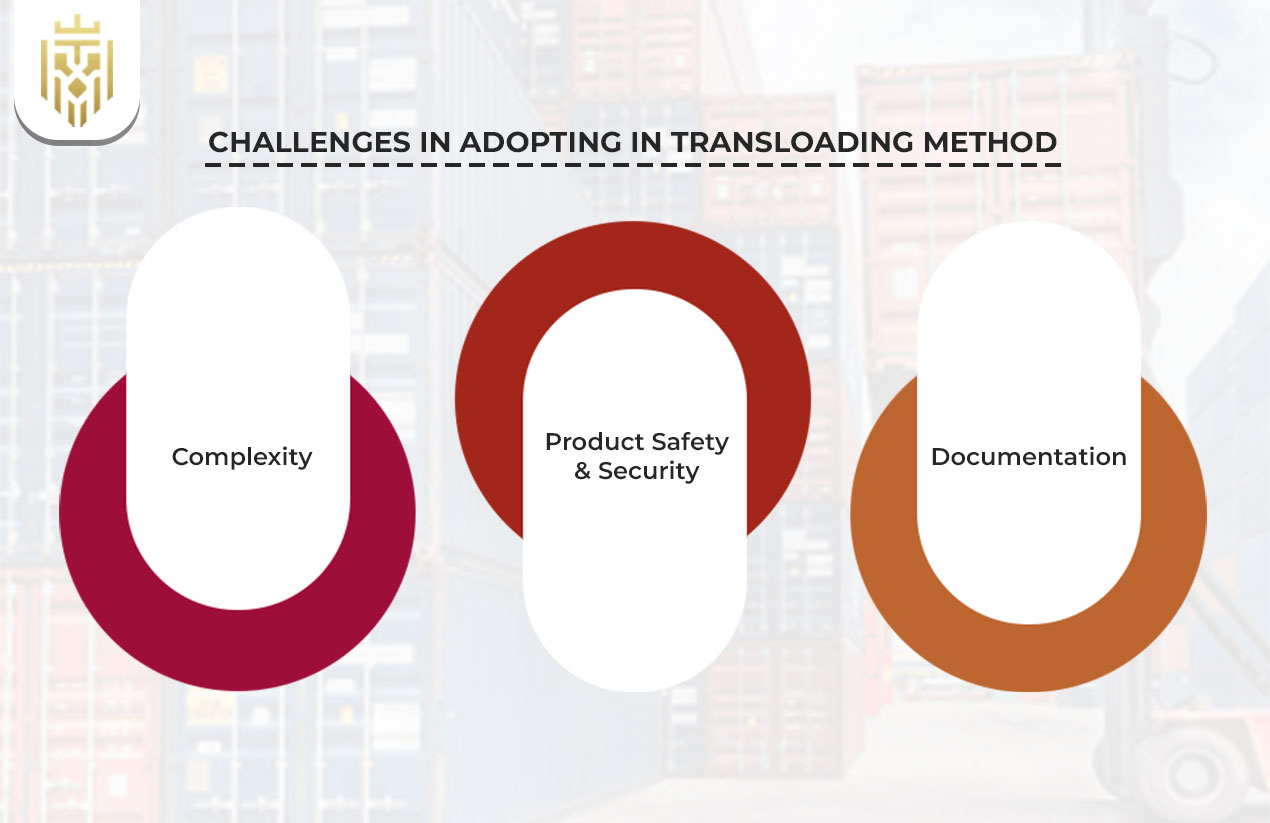

Challenges in Adopting in Transloading Method

Although beneficial, transloading comes with certain challenges that businesses must manage. Complexity, safety concerns, and documentation requirements are the main barriers.

Complexity

Having to coordinate multiple modes, carriers, and facilities creates complexities. It is necessary to have advanced planning alongside reliable partners if one is to maintain smooth operations. An unsystematic procedure without rigid structures will cause errors and delays to impair the entire supply chain.

Product Safety & Security

Frequent handling has an increased risk of damage, theft, or going astray. Protection mechanisms with arguably adequate staff skill set must come together to reduce insecurity. To further safeguard products, it is going to be a worthwhile investment for a company to employ monitoring systems and secure storage facilities.

Documentation

Every transfer entails additional paperwork, customs forms, and compliance checks. If unchecked, delays might cause shipments to fall behind. With the help of digital platforms and automation, the whole process can be streamlined while cutting down on human error.

Optimising Transloading Operation

Businesses can optimise transloading through technology, strategic facility locations, and skilled providers. Implementing automation and digital tools further improves accuracy and reduces costs.

Advance Tracking Tools

Digital tracking systems provide real-time visibility of goods throughout the process. This transparency reduces errors and increases customer confidence. By integrating with supply chain platforms, tracking tools also support proactive decision-making.

Experienced Service Providers

Reliable partners ensure the flawless handling of consignments. Having experience equates to minimising possibilities for delay, damage, or violations in compliance. In addition, well-established providers carry systems that are time-tested for improving efficiency at every step.

Streamlining Transloading Network

Optimised networks avoid futile routes and fetch unnecessary delays. A well-designed network, therefore, provides a good balance for the cost and speed of delivery. It also gives businesses the much-needed agility to quickly shift between disruptions or altered supply demand.

Strategically Located Transloading Facilities

Such facilities are capable of cutting transport costs when near to the ports, rail hubs, or big markets. The location itself determines about efficiency and delivery timing. It helps inter-domain operations as well as international operations with key corridors at their side.

Incorporating Automation for Better Cargo Handling

With such automated machines, the chance of a human error is extremely minimized. This increases accuracy and decreases many faults that come in with manual handling. Whereas, over time, this automates scalability and ensures businesses meet the rising expectation of customers.

FAQs

1. Can transloading be applied to temperature-sensitive goods?

Yes, these are any sort of cold-storage warehouses in which activities related to sweeps may be accomplished safely for perishable items. This keeps the food fresh and cuts down on food wastage.

2. Is transloading suitable for hazardous materials?

Yes, hazardous goods can be transloaded provided that the strict regulations and safety standards are followed. The special equipment and trained personnel are available for use.

3. Does transloading affect shipping timelines?

If well managed, transloading will reduce delivery times instead. More flexible routing and quick last-mile distribution may be offered.

4. What role do transloading facilities play in international trade?

They serve as important hubs, linking the goods to different modes for worldwide distribution, thus binding together international supply chain networks.

5. What factors should be considered when choosing a transloading partner?

The location of the facility, expertise in handling, compliance knowledge, cost efficiency, and reliability is some consideration.