What is Supply Chain Disruption?

Supply chain disruption is a term used to denote unforeseen occurrences that end up disrupting the normal course of goods and services within the global chain. In order to master supply chain processes, it is important to know what supply chain disruption means because it brings out risks involved that impact shipping, production and delivery.

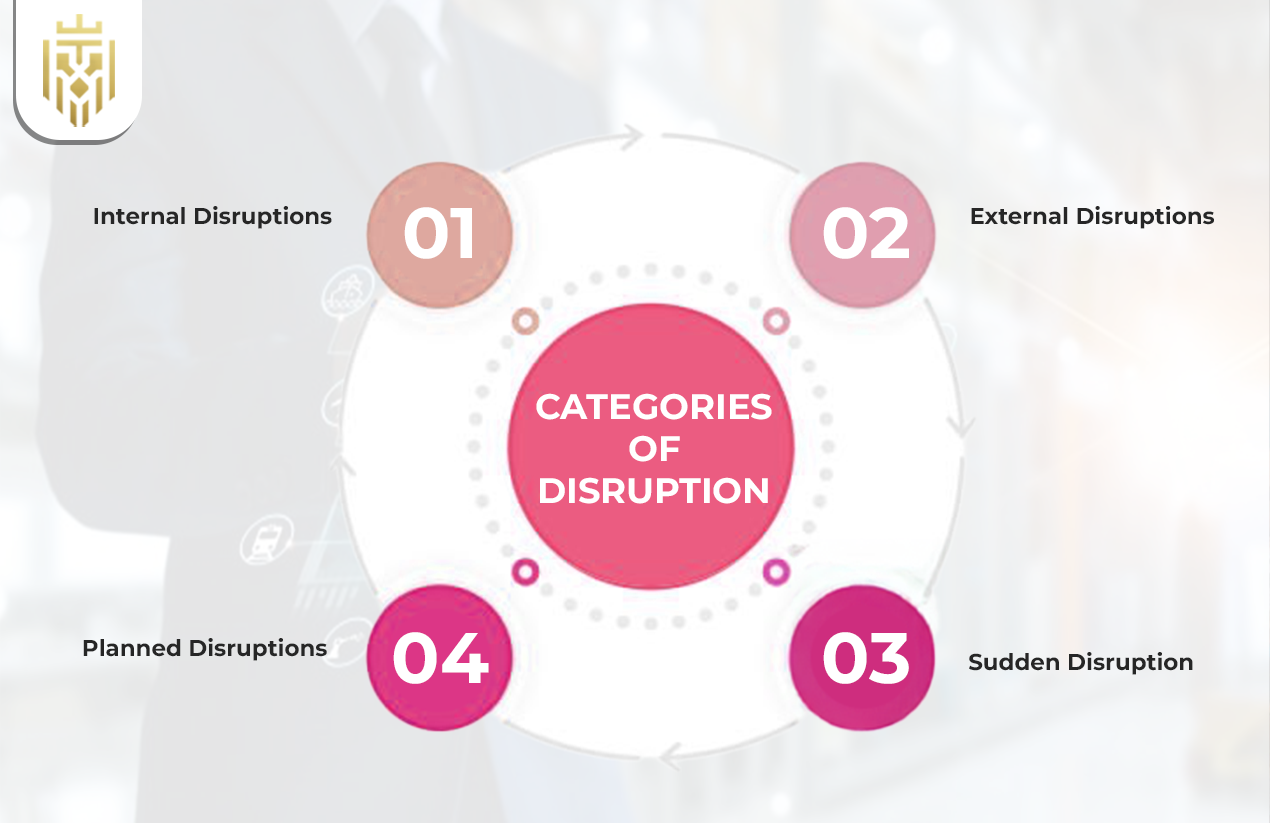

Categories of Disruptions

The disruptions to the supply chains could be displayed as both internal and external, sudden as well as planned. Such reasons influence worldwide activities, transportation, and stock. Businesses have to know each type of supply chain to learn supply chain resilience and aim at controlling supply chain disturbance.

Internal Disruptions

Internal disturbances are due to elements inside an organization, such as machine breakdown, workforce or production error. Controlling the problem of supply chain disruption caused by internal factors will reduce the delays and the shipping process will be smooth even with these unforeseen disruptions in the supply chain.

External Disruptions

External supply chain interruptions come about because of external forces such as natural catastrophes or geopolitical upheavals or worldwide pandemics. Such reasons devastatingly impact on shipping, availability of resources, and production schedule. Companies have to be taught the supply chain strategies to deal with the disruption in the supply chain.

Sudden Disruption

Sudden disruptions in the supply chain occur mostly because of accidents, cyberattacks, or extreme weather-related disasters. Global events can have tremendous consequences like shipping patterns, availability of products and survival of businesses.

Planned Disruptions

Scheduled maintenance, planned system upgrades or reconfiguring the organization are some examples of planned disruption to the supply chain. Even though expected, these reasons may interfere with the shipping schedules and services. Therefore it is vital to deal with supply chain disruption via contingency planning.

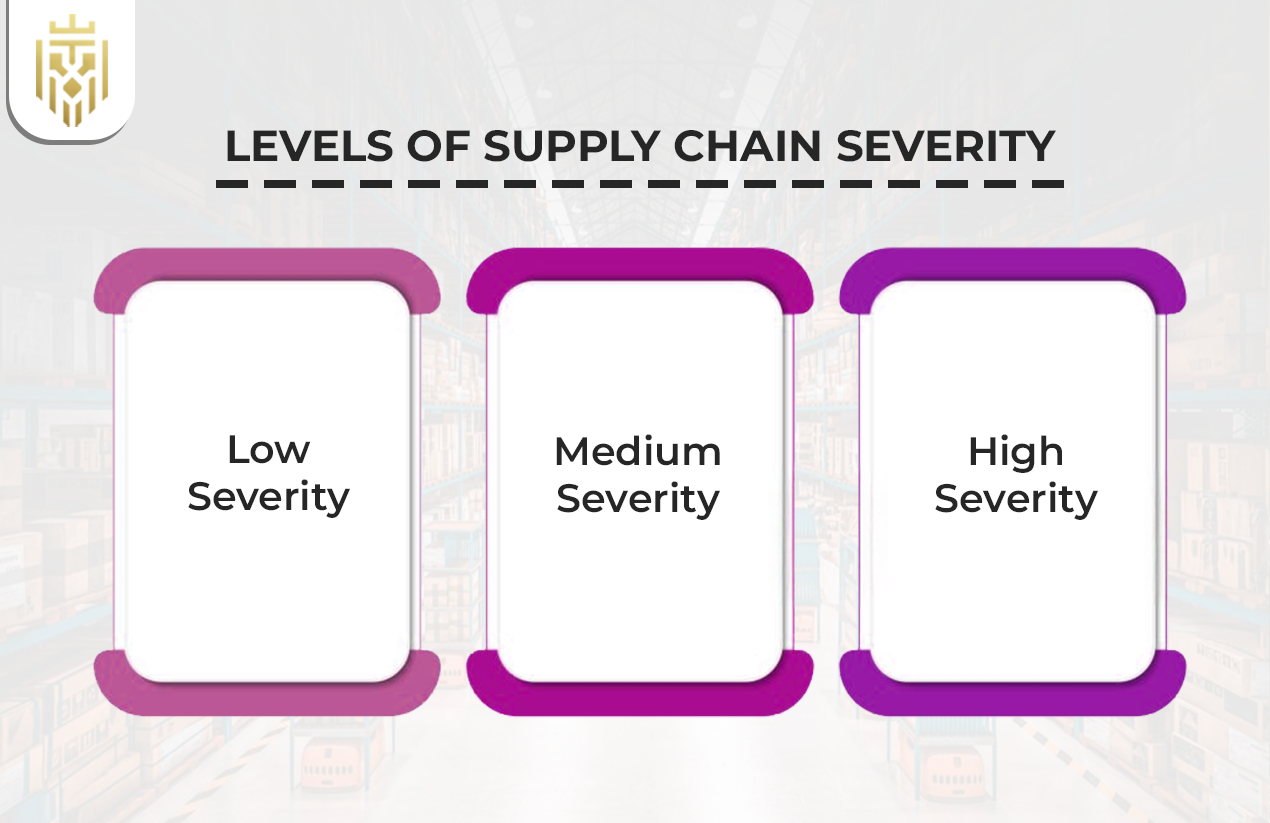

Levels of Supply Chain Severity

Suppliers disruption can be low, medium or high based on the effect to the operations. Learning about these levels enables companies to understand supply chain weaknesses and ways of dealing with disaster caused supply chain effectively within its international operations and transportation systems.

Low Severity

Minor impacts on the operations are associated with low severity of supply chain disruptions. This causes delays in shipping or availability of products although it can be solved easily. In order to learn supply chain resilience, even these minor causes should be addressed properly by companies.

Medium Severity

Supply chain disruptions of medium severity result in marked production delays, or a shipping bottleneck. The effect goes as far as scarcity of resources or customer dissatisfaction. To deal with supply chain disruption at the respective level, it is necessary to respond timely and increase visibility along the global supply chain.

High Severity

Major operational crises are caused by high-level supply chain disruptions. The effects involve the suspension of manufacturing, the interruption of deliveries, and loss of revenues. To manage these causes on global bases, it is important to understand the meaning of supply chain disruption and develop effective risk management systems.

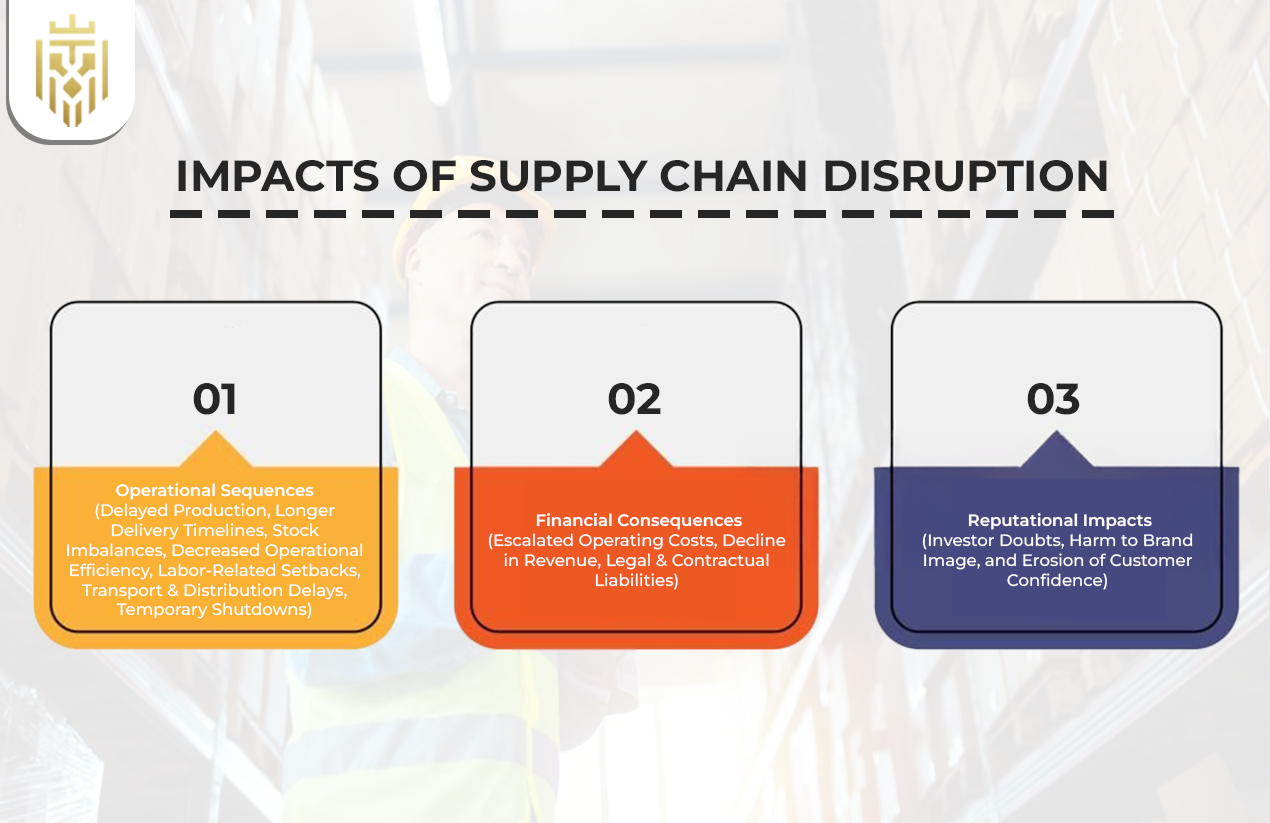

Impacts Of Supply Chain Disruption

At the effect of a supply chain disruption, there are production time wastage, lost finances and lost reputation. Firms in international markets ought to know about the threat of supply chains and enhance the supply chain interruption overseeing strategies to avert the problem of shipping and business failure due to unexpected reasons.

Operational Sequences

The disruptions in the supply chain impede the flow of operations of the process of procurement, production, and shipping. The effect is felt in terms of delays, cost increment and reduced competitiveness. In order to acquire knowledge of supply chain stability, companies will need to study these patterns and enhance governance of the processes of disruption of supply chains.

Delayed Production

When materials or resources are unavailable, then delayed production is being a direct effect of interruption in the supply chain. All these global supply problems are caused by different factors such as the failure of the logistics or the back ups of the suppliers, which delays manufacturing and disrupts shipping schedules.

Longer Delivery Timelines

Delays in supply chains are likely to create delays in the delivery process. Common reasons of delay in shipping may include global events, port congestion, strikes in transportation. The firms should also be concerned with supply chain disruption in order to address the customer set expectations.

Stock Imbalances

The imbalance in stocks is possible because of disturbances in the supply chain leading to stock outs or excess stocks. Such reasons interfere with inventory control and accuracy of shipping. In order to understand the resilience of the supply chain, a company needs to create principles of managing supply chain disturbance as well as changes in demands.

Decreased Operational Efficiency

Incidence of disruption in the supply chain considerably decreases efficiency in operations. Some of the causes are poor visibility, shortage of resources and shipping delays. The effects dilute productivity and it is of great essence that organizations invest in the techniques of managing supply chain interruption.

Labor-Related Setbacks

Supply chain disruptions are a consequence of labour strikes, shortages of skill, or health crisis. These reasons reduce production, shipping is delayed, as well as the whole chain of supply around the globe. The companies have to engage the issue of labor-related risks in order to learn the sphere of supply chain management.

Transport & Distribution Delays

One of the typical consequences of the supply chain disruption is transport and distribution delays. The common slowdown factors in shipping are traffic congestion, incidences in weather or infrastructure failure. Supply chain disruption can be managed through enhancement of logistics and diversification of means of transportation.

Temporary Shutdowns

The temporary shutdowns are where shutdown occurs due to the disruption of the supply chain. Examples of the best causes are global crises, failures of suppliers, or regulatory problems. The knowledge of the definition of supply chain disruption and the enhancement of response strategies can reduce such shipping and production delays.

Financial Consequences

Actions that cause problems in the supply chain result in increased expenses, loss of revenues, and legal claims. The profitability is directly affected by these causes. As the means of staying competitive in the international markets is to learn supplying chain damaging protection and centre attention in controlling the interference of the supply chain.

Escalated Operating Costs

The consequences of a breakdown in supply chains tend to make the costs of operations increase. Surprising situations such as late delivery of orders and materials bring companies to incur expenses. To cut such costs, supply chain disruption management should be used to teach companies how to manage the stability of their supply chains.

Decline in Revenue

An interruption on a supply chain may directly cause a decrease in revenue. Either delaying shipping or stoppage of production can denote a huge loss in profitability. To ensure that such impact is reduced, businesses should learn supply chain strategies on how to handle disruption of the supply chain.

Legal & Contractual Liabilities

Disruption in supply chain may result to severe legal and contractual liabilities when parties fail to deliver on contracts. Familiarity with the disruption of the supply chain meaning assists companies in their global challenges, shipping delays, and financial fines, which makes it essential to resolve supply chain disruption proactively.

Reputational Impacts

Break down of supply chain can hurt the brand image, the investor trust and confidence of the customers. Such reasons exert a long-term consequence on business success. Business firms should attain the art of protecting the supply chain and perform optimally when handling the supply chain spoilage, particularly in international trade and transportation.

Investor Doubts

Disruption in the supply chain leads to uncertainty leading to investor concerns whether the supply chain disruption is global, as it is a major concern. Its effect destroys trust and economic security. Organisations need to learn how to be resilient with their supply chains in order to restore trust and take control over supply chain disruption to ensure long term reputation is not negatively affected.

Harm to Brand Image

The effect of brand image may be disastrous when the disruption of supply chains creates delays in shipping or shortages of products. To avoid such global challenges, the business must learn how to remain resilient in its supply chain and concentrate on how it will control the disruption in the supply chain to avoid jeopardising its market reputation.

Erosion of Customer Confidence

Customer confidence is easily lost in the face of a supply chain hitch, more so in cases where delays in goods shipments and stock out situations become common. The meaning of a supply chain interruption and the reasons of its happening allow companies to establish customer retention strategies and pay attention to managing the supply chain interruption in global settings.

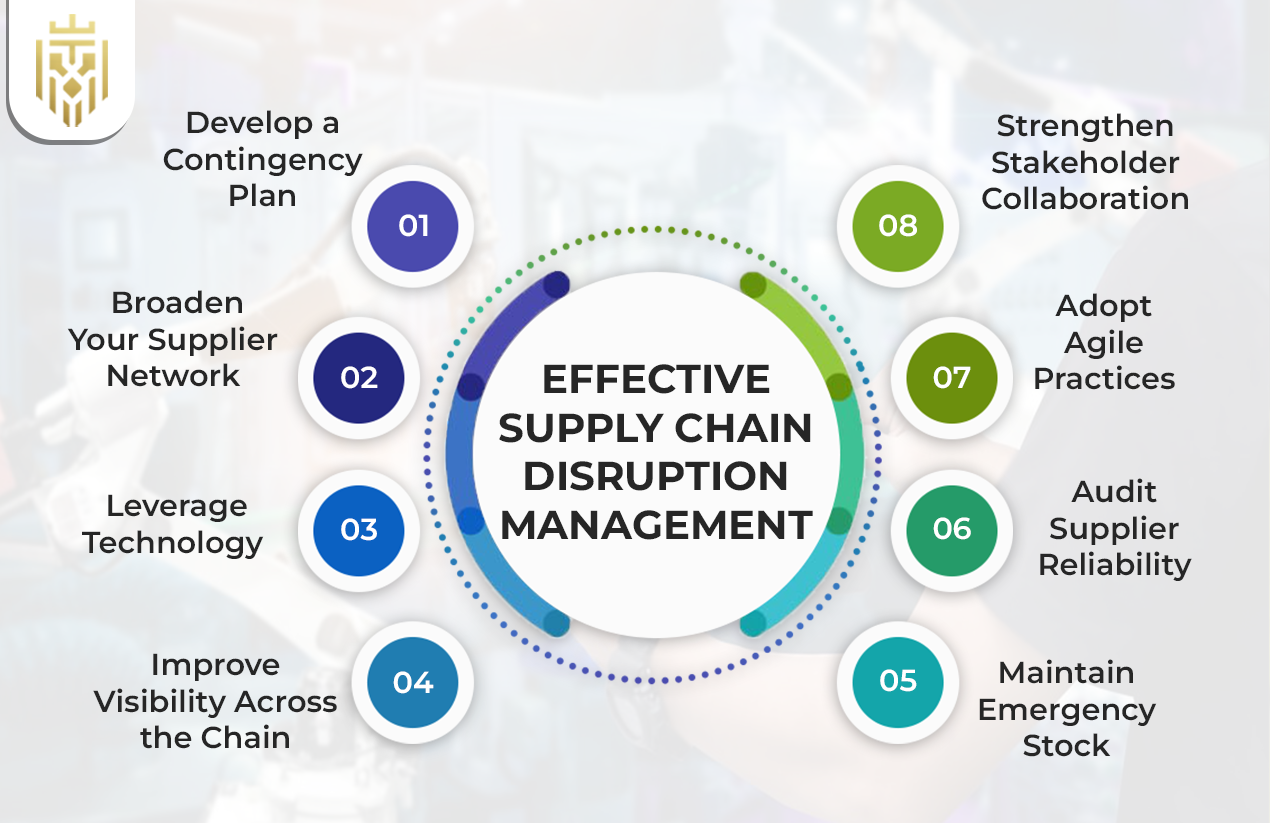

Effective Supply Chain Disruption Management

Contingency planning, dependable suppliers, and flexible processes are effective to manage the disruption of supply chains. The businesses should learn supply chain resiliency, increase supply chain visibility, and protect the business against the causes of disruption to the global shipping operations. In case there is a supply chain disruption, there should be minimal disruptions to business.

Develop a Contingency Plan

To control the supply chain disruption, it is necessary to develop a contingency plan. It makes businesses ready of worldwide shipments that become unavailable and unreliable. In learning the supply chain strategies, companies need to focus on reducing the risk and mitigate the consequences of possible supply chain failure within the shortest time possible.

Broaden Your Supplier Network

Having a wide supplier base lowers the damage of supply chain interruptions. Distributing suppliers, in different parts of the world, reduce the focus on one source. Firms wanting to study supply chain resilience need to broaden their alternatives so that shipping is reliable and that supply chain disruption can be handled effectively.

Leverage Technology

A tool in managing disruption in the supply chain is through leveraging technology. Real-time tracking helps to eliminate shipping problems and point out the causes of the future supply chain breakages. Businesses are required to adopt newer technologies to study supply chain processes effectively so that they can reduce the effects of global supply chain threats.

Improve Visibility Across the Chain

The key in supply chain disruption management is to improve visibility. Transparency in the chain allows determining the causes promptly, regulating global shipping channels, and limiting the effect of supply chain failures. A real-time monitoring and proactive control are the focal points of companies striving to learn more about supply chain resilience.

Maintain Emergency Stock

One important action in this disruption of the supply chain is keeping an emergency stock. Buffer inventory cushions the effects of international shipping delays and any unforeseen imbalance to the supply chain. Businesses need to invest in safety stock to deal with the unforeseen causes to learn supply chain preparedness.

Audit Supplier Reliability

Supply chain disruption can be managed through regular supplier audits guarantee supplier reliability. These controls reduce the occurrence of global cargo issues and minimize the effect of the supply chain interruptions. To eliminate hidden causes and to establish sound networks, firms should be taught the methodologies of supply chain evaluation.

Adopt Agile Practices

It is imperative that agile practices are adopted in the process of supply chain disruption management. Due to diverse reasons underlying supply chain failure, flexibility assists businesses to counter shipping crisis around the globe. Firms that gain agility in supply chain can reduce the effect and move fast with those changing market conditions.

Strengthen Stakeholder Collaboration

The positive relationship with the stakeholders helps to control the disruption of the supply chain. Collaborating with partners reduces the effect of global shipping delays and other supply chain interruptions. Businesses have to establish trust-based relationships to collectively tackle disruption causes to learn supply chain dynamics effectively.

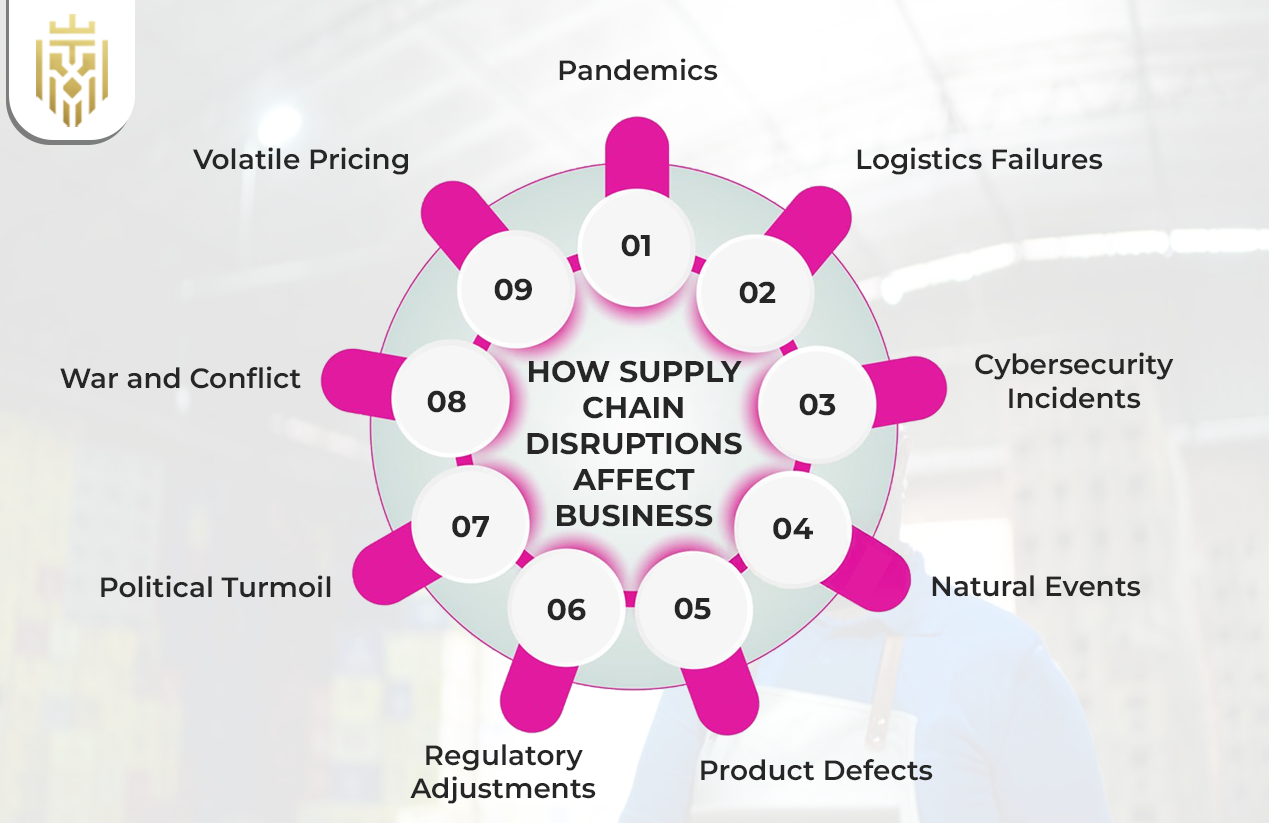

How Supply Chain Disruptions Affect Business?

Business impacts of supply chain disruptions include delayed shipping, idled production, and cost escalations. Their effect may negatively affect brand recognition and profitability. Businesses should acquire the art of supply chain preparedness and come up with powerful systems to manage supply chain disruption particularly in international undertakings through different triggers.

Pandemics

Pandemics have been identified as one of the greatest sources of corruption of supply chain characterising by worldwide disruption of shipping and intense damage to business continuity. Firms need to master supply chain risk-management techniques, and concentrate on managing supply chain disruption to sustain supply flow in unpredictable pandemic-type situations.

Logistics Failures

Logistics failures tend to cause breakdowns in the supply chain, hence stopping shipping and movement of products. The aftermath may cripple the functioning of the markets in different parts of the world. In order to learn about supply chain resilience effectively, businesses must devise strong logistic plans that lay emphasis on supply chain disruption management in a quick manner.

Cybersecurity Incidents

When these events disorient shipping information and international activity, the cases of cybersecurity are increasing as the cause of disruption of supply chains. The effects may be fierce. Businesses are required to be taught on the use and application of supply chain security in order to protect systems, yet proactively to handle disruption in the supply chain.

Natural Events

When supply chains break, it is usually due to natural disasters such as floods, earthquakes, which displace the freight and vehicles and destroy the infrastructure. These natural causes can be diminished with learning supply chain disaster planning and immediately handling a supply chain disruption.

Product Defects

One of the shrouded disruptions in supply chains is defective products, which on most occasions result in recalls and shipment halts. Its effect can be far reaching in the world markets. Supply chain quality controls should be learned by companies in order to discuss some control over supply chain disruption and to start managing it very successfully.

Regulatory Adjustments

Changes in regulation are also major contributory factors to supply chain breakdowns, particularly during the abrupt alteration of international shipping regulations. The effects are normally direct and expensive. Such a changing legal environment requires businesses to study supply chain compliance and to concentrate on control over supply chain disruption.

Political Turmoil

Supply chain interference is often caused by political unrest that manifests in international shipping blockades and trade embargos. The effects may destabilise the whole supply chains. The businesses are advised to learn the concept of supply chain contingency planning and develop ways of dealing with geopolitical rampage in supply chains disruption.

War and Conflict

War and conflict lead to disruption in severe supply chain alteration since they disrupt the global route of supplies and lead to security problems. The effects are contagious to industries. Companies which educate on supply chain risk responses find themselves better placed in dealing with supply chain disruption in the event of such massive emergency.

Volatile Pricing

One of the financial factors of disruption in supply chains is volatile pricing, particularly where shipping across the world is adversely affected by fluctuation in shipping costs. Such an influence on budgeting and sourcing is significant. Businesses have to study the supply chain cost policies and master the issue of supply chain disruption by volatile prices.

Ensure Supply Chain, regardless of Disruptions with Jones Elite Logistics

By using Jones Elite Logistics, business can entrepreneurially address supply chain disruptions with proactive global shipping solutions and multi-modal disruption management. Our team assists you to understand supply chain resilience, causes, and how to manage disruption of goods to reduce its effects and guarantee smooth functioning of business.

FAQs

1) What is Supply Chain Disruption?

A supply chain disruption refers to unexpected events interrupting product flow, delaying shipping, or halting operations. Understanding supply chain disruption meaning helps businesses learn supply chain risks and focus on managing supply chain disruption, especially in global markets.

2) What are the strategies of supply disruption management?

Effective managing supply chain disruption involves building supplier diversity, improving visibility, maintaining emergency stock, and using technology. Businesses must learn supply chain risks, anticipate causes, and strengthen global operations to reduce impact from unexpected supply chain disruptions, especially affecting shipping.

3) What are the Levels of Supply Chain Disruption?

Supply chain disruptions vary in severity—low, medium, or high—based on their impact. Understanding these levels helps businesses learn supply chain vulnerabilities, anticipate causes, and excel at managing supply chain disruption, particularly across global operations and critical shipping activities.

4) What can cause supply chain disruption?

Common causes of supply chain disruptions include natural disasters, supplier failures, pandemics, and political instability. These disruptions affect global trade and shipping. Businesses must learn supply chain dynamics and prioritise managing supply chain disruption to minimize operational impact.