What Drives an Efficient Logistics Operation?

Efficient logistics operations witness every successful business. It moves its products from manufacturing right into delivery. Customers see only the end result: on-time product delivery in impeccable condition. The real work remains hidden behind the scenes. Various logistics management functions act like moving parts of a machine, individually performing their function but dependent on one another for complete efficiency.

Why Mastering Logistics Functions Makes a Difference

A company can be a company of the best products, yet its customers suffer from retarded delays, damages, or errant orders because of weak logistics functions. To master logistics is to have control, to improve visibility, and to develop a reputation for reliability. When done right, businesses keep costs down and simultaneously create the experience to which customers look as trusting a much more substantial value than price.

Adapting Logistics to Meet Today’s Challenges

The logistics world is not without its challenges. Global supply chains face disruptions such as port congestion, rising fuel prices, and demand fluctuations. Small errors in one function can ripple across the supply chain, creating larger inefficiencies. To overcome these, logistics functions must adapt to new technology, smarter planning, and better coordination. The ability to stay flexible ensures that businesses can serve customers even in the most uncertain conditions.

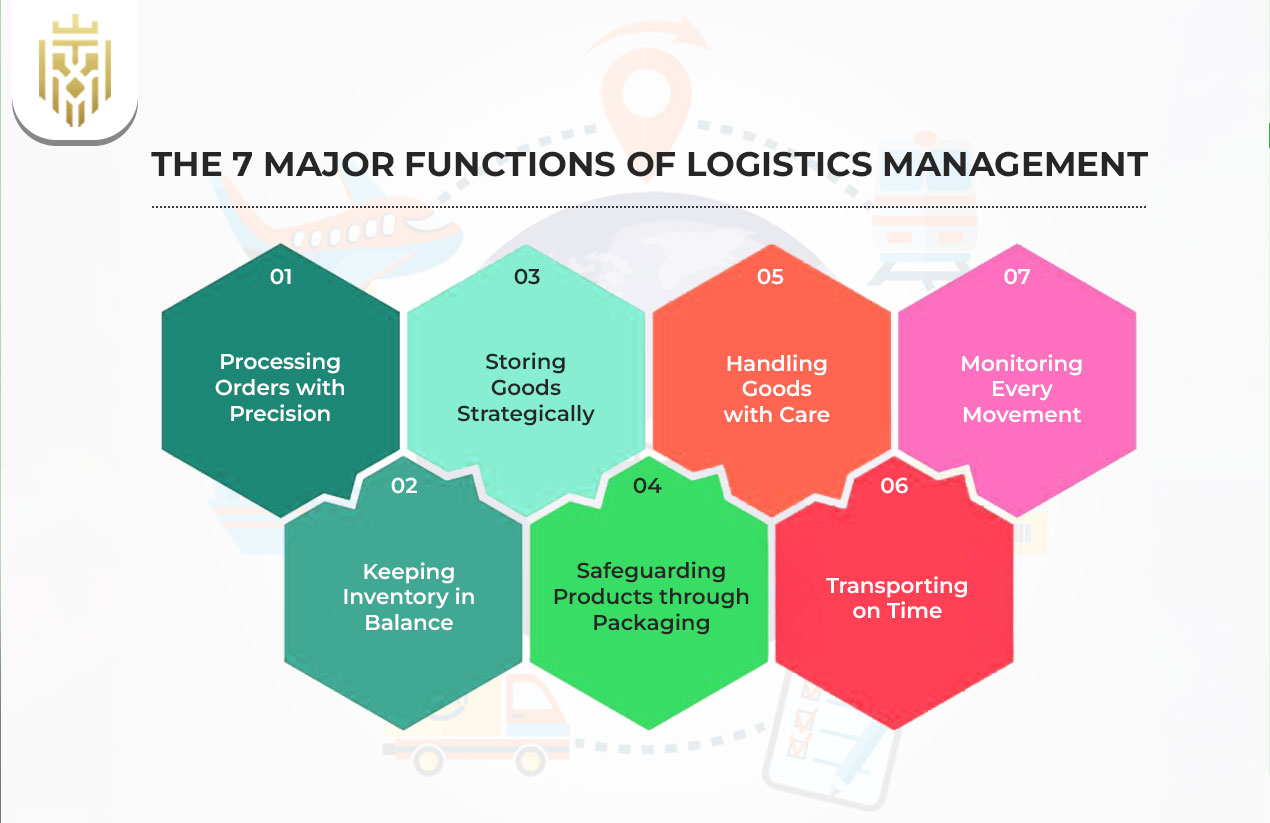

The 7 major functions of logistics management

The 7 major functions of logistics form the backbone of any successful supply chain. Here’s how each one contributes to performance and reliability.

Processing Orders with Precision

Order processing is the starting point for almost all logistics activities. Any kind of wrong data entry into orders because of either a faulty system or human error may lead to a delay in delivery or wrong delivery that eventually leads to unhappy customers. So order processing helps to ensure a smoother operation along the supply chain.

Keeping Inventory in Balance

A key activity in inventory management is maintaining adequate stock levels to prevent overinvestment in storage and to avoid loss of sale due to stock-outs. On-time adjustment of inventory levels with the help of forecast-based demand and inventory verification techniques to accommodate demands ensures the agility of the business in meeting customer demand. The overall objective of inventory balance is waste reduction and increased responsiveness.

Storing Goods Strategically

Warehousing is all about efficiency. Layout-wise, it should make it easy to pick, pack, and dispatch goods quickly. Location-wise, it makes sense to position warehouses closer to customers to help reduce delivery times and transportation costs.

Safeguarding Products through Packaging

Packaging is not just a pretty face; it gets products safely to their destination. Hard-to-damage packaging at a reasonable price lowers the chance of accumulative damage to the product, returns, or keeping costs aloft. In contrast, designs that reflect sustainability and branding also improve customer experiences and support green goals.

Handling Goods with Care

Products go through many touchpoints before reaching the customer. Safe handling and efficient handling reduce damages and accidents, and this is backed by trained staff and proper equipment. In instances where speed is essential, fine-tuning the cheapest ways by means of automation may not necessarily compromise safety; a few examples would be autonomous forklifts, conveyors, and sorters

Transporting on Time

Whereby transport is the most liquid and expensive segment of logistics, success lies in the goods’ delivery being reliable, cost-effective, and timely. Businesses maintain timely delivery and uphold their reputation by fabricating a strong relationship with carriers, defeating routing challenges, and offering real-time tracking.

Monitoring Every Movement

Visibility is essential in modern supply chains. Real-time monitoring allows companies to track shipments, resolve disruptions quickly, and analyse data for improvements. This continuous oversight ensures efficiency and helps businesses meet growing customer expectations.

Maximising Efficiency Across Each Function

The strength of logistics lies in refining every step. Below are strategies businesses use to enhance efficiency in the 7 functions.

Building Order Systems That Flow

Smooth order systems are free from bottlenecks. With orders growing by the thousands, it would be hard to maintain accuracy without an automated order entry system, electronic data interchange, or a centralised platform. When systems flow, delays are cut short, and customers get served quicker.

Automating Stock Checks

In days gone by, stock would be manually counted. Inventory is checked automatically through scanners, RFID systems, and integration, and such systems give accurate data in real time. Error reduction and maintenance of stock level accuracy are enabled through automation.

Designing Smarter Storage Setups

A warehouse’s configuration determines speed and productivity. Better layouts, like zoned storage and vertical racking, cut down walking time and improve picker efficiency. Better layouts also improve safety and reduce labour costs.

Packaging That Cuts Waste and Cost

Packaging efficiency is a matter of compromise between protection and cost. Modern designs and materials therefore minimis e waste while ensuring that their durability is not in question. Firms opting to dye their packaging similarly save costs in transport by reducing weight and overall dimensional volume.

Streamlining Handling Processes

Handling is made efficient by training and standardisation. Implementing clear processes and installing the right equipment allows businesses to minimise damages and speed up operations. Streamlined handling hence directly affects operating costs and lowers them.

Routing with Real-Time Optimisation

Intelligent routing is the backbone of logistics. Real-time optimisation covers traffic and weather patterns and adjusts delivery routes instantly to shorten delivery time and conserve fuel and ultimately protect the environment.

Tracking and Analytics Dashboards

A tracking tool does not just feed data; it generates insights. Analytics dashboards allow businesses to track KPIs like delivery accuracy, transit time, or cost per shipment. These insights then mould better decision-making and build better performance as time elapses.

Logistics Wins from Getting It Right

When the 7 major functions of logistics are executed well, businesses experience stronger supply chains and happier customers.

Reduced Delays & Fewer Errors

Proper logistics eliminate common errors. The orders are generated correctly, and goods are appropriately stored; transport runs smoothly-the end result being fewer delays and enhanced reliability.

Lower Overhead, Smarter Spending

Every inefficiency adds to logistics costs. In maximising the efficiency of all functions under his control, the businessman reduces waste, inventories, storage costs, and even fuel. Smart spending makes for profitable supply chains.

Better Customer Confidence

There is one thing the client really values: reliability. The right product, at the right time, in the right condition builds confidence and loyalty; good logistics management is usually the way to turn an initial buyer into a long-time client.

Logistics That Scale with Your Business

The greatest advantage must be scalability: a logistics system proficient in these functions shall be capable of growing with the business. New markets or seasonal spikes-structured logistics can modify without cracking.

FAQs

1) What are the 7 major functions of logistics management?

These encompass order processing, inventory management, warehousing, packaging, handling, transportation, and monitoring. Each function contributes to the design of a smooth and reliable supply chain.

2) How do these functions interconnect?

They work sequentially—orders go into inventory planning, inventory gets linked to warehousing, and transport depends on packaging and handling. Monitoring is done over the entire system to ensure it works as expected.

3) What happens when a logistics function fails?

Analogously, one function’s failure will often trigger another; for instance, poor inventory management causes orders to be delayed, which then means transport schedules get disrupted and ultimately results in a disappointed customer.

4) Which function delivers the most ROI for businesses?

Transportation and inventory management are usually the two functions that bring the greatest return on investment due to them directly affecting the costs and customer satisfaction; however, true ROI is derived when all seven functions operate in harmony.