What is an Automated Guided Vehicle?

Automated guided vehicles, sometimes referred to as AGVs, are a type of automated machine that can transport goods, such as pallets, containers, and other materials, from one location to another without requiring any manual help. Automated guided vehicles can use advanced navigation systems, sensors, markers, or other forms of guidance to move along a set course and complete their deliveries. In contrast to human-operated machinery like forklifts and trolleys, AGVs can function without breaks, can be counted on to deliver the same high level of performance every time, and remove the chance of error. In modern warehouses, these machines silently operate in the background, playing a crucial role in automation by cutting down on the time, cost, and risk associated with transporting goods.

Importance of Automated Guided Vehicle System in a Warehouse

The arrival of an automated guided vehicle system spells a major advance in the efficiency of warehouses. A warehouse is often overwhelmed by a shortage of workers, safety concerns, and increasing order volumes. By automating tedious and repetitive material handling, AGVs not only improve the accuracy of stock movement but also eliminate delays and reduce bottlenecks. They are also able to operate continuously, which is crucial for e-commerce and manufacturing industries. AGVs offer an increasing return on investment and can adapt to increasing workloads to meet the evolving demands of a company, making them the ideal investment for companies aiming to streamline their warehouse processes.

How do Automated Guided Vehicle systems work?

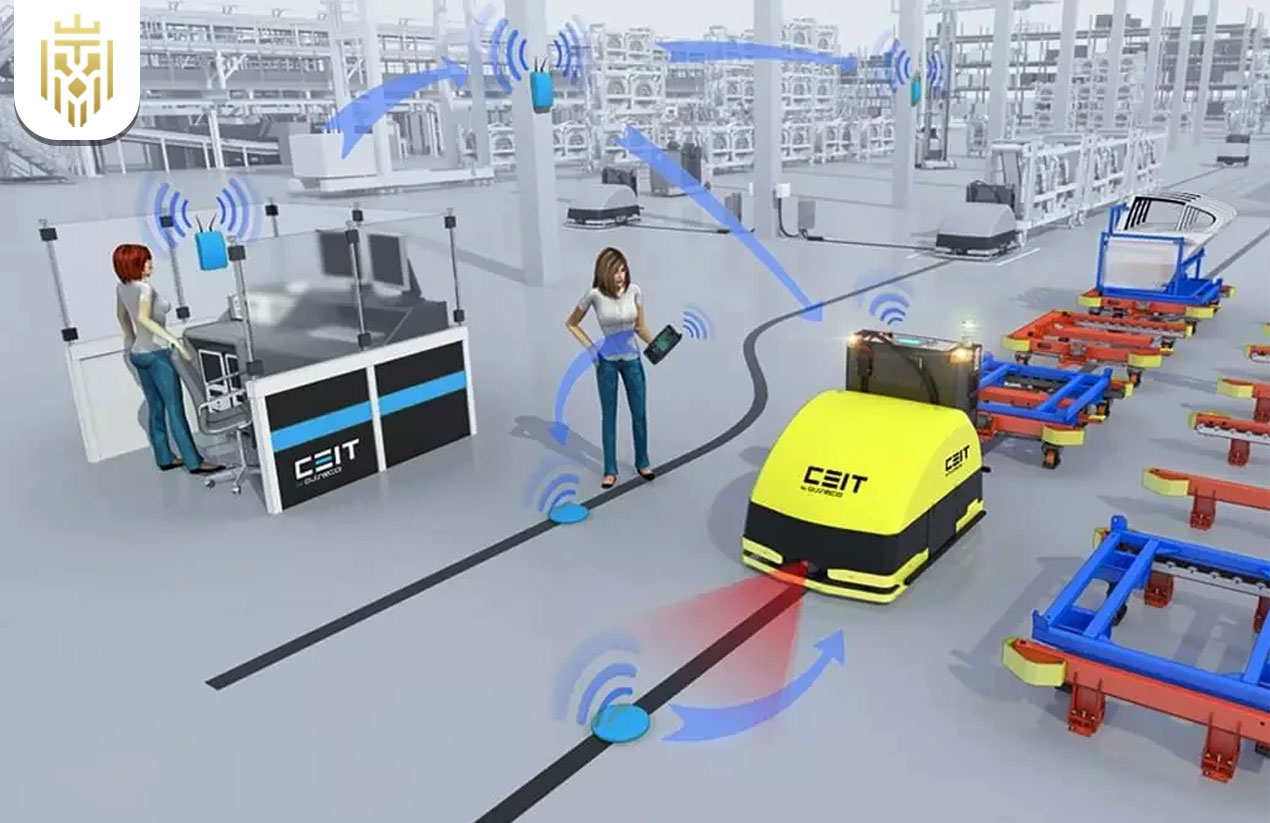

AGVs rely on a combination of navigation, safety mechanisms, and communication systems to operate effectively. Together, these technologies ensure goods move quickly and accurately, even in busy warehouses.

Navigation

Navigation is at the heart of AGV operations, requiring vehicles moving through warehouses to operate without human intervention. It allows AGVs to stick to very defined paths; however, operational constraints may require them not to do so in certain situations.

Magnetic Tape

One of the simpler ways is to lay magnetic tape on floors, thus guiding AGVs on fixed routes. This method is cheap and reliable; however, it lacks flexibility should layouts undergo frequent variations. Hence, this method suits operations that are stable and repetitive.

Optical Navigation

Optical navigation implies using cameras or sensors to detect lines or markings on the floor. This method is more flexible than using magnetic tape and allows paths in warehouses to be altered without massive reinstallation works. Hence, this would be useful in dynamic layouts where change is required on business demand.

GPS Navigation

For large or complex warehouses, GPS-based systems provide advanced navigation. By combining GPS signals with warehouse maps, AGVs can move across vast spaces and reroute themselves if obstacles appear. This approach supports maximum flexibility for high-volume operations.

Obstacle Detection Safety

Safety is critical when AGVs operate alongside human workers. Obstacle detection ensures that vehicles avoid collisions and keep workflows uninterrupted.

Ultrasonic Sensors

These sensors scan the surroundings for obstacles and cause the AGV to slow or stop whenever people, machinery, or goods get in the way. They act as the AGV’s eyes, constantly keeping in touch with the environment.

Emergency Stop Buttons

Emergency stop buttons are fitted into AGVs, allowing human workers to stop the vehicle immediately should any unforeseen situation arise, creating an added layer of safety. This manual override guarantees human control during emergencies.

Communication

To perform tasks efficiently, AGVs need seamless communication with warehouse systems.

WiFi

WiFi connections empower AGVs by giving live instructions, reporting progress, or changing routes in real time. Therefore, real-time responses can be instantaneously made and hands-on coordination across warehouse operations.

RFID Tags

RFID tags dropped around a warehouse give an AGV checkpoint to confirm position so passing can be carried out with precision and reliability. They secure the location even when WiFi services may stay weak.

Applications of Automated Guided Vehicles in Warehouses

AGVs are versatile tools that serve multiple functions in warehouses, making them invaluable for logistics efficiency.

Pallet transport

With the main application of transporting pallets from receiving to storage to shipping, the AGVs have gradually taken the place of forklifts for a faster movement of materials. Automating this process reduces accidents and increases throughput for the warehouse.

Order Picking

Order picking is one of the most time-consuming activities in a warehouse. AGVs not only bring goods to workers but also can carry out picking themselves, thereby greatly reducing walking time and speeding up fulfilment. Sounds good for productivity; however, in return, the workers get tired much less.

Distribution

In addition, AGVs support internal distribution of goods by moving them from one zone of the warehouse to another, thus ensuring that stock reaches the appropriate department or area at the exact time it is needed, avoiding any delay. Hence, timing and coordination of the entire supply chain run better.

Advantages of AGV

Like any technology, AGVs bring clear benefits that make them a valuable investment for warehouses.

Reduced labour costs

They cause a drop in manual labour during the transport of goods via repeated operations. While staff cannot be entirely replaced by it, such reduction cuts down on overtime, hiring, and training costs. Over time, these costs get transferred to areas of higher-value work in which human judgement plays a role.

Increased Safety

An accident at the workplace due to fatigue, distraction, or heavy machinery would be costly, possibly threatening life. The safety laws that were imparted in programming are adhered to by AGVs, which reduces luminescence-related hazards to employees in a bustling environment. Due to the predictable movement pattern of AGVs, the working space around them is also safer for employees.

Productive

In fact, AGVs never call in sick, never have a bad hair day, never take lunch breaks, and never clock out for the day. They work 24/7 and move loads even during off hours, thereby increasing throughput capacity during the peak demand season and bolstering services for export demand in the global market.

Disadvantages of AGV

While AGVs bring major benefits, they also come with challenges that businesses need to consider before adoption.

High Implementation Costs

The highest stumbling block for AGV implementation is the initial investment. From the purchase of the vehicles to installing and setting up the navigation systems and integrating with warehouse management software, the costs can be pretty high. Many organisations, however, recoup these costs given labour savings and efficiency gains over a period. It is essential to carry out a thorough ROI analysis before moving forward.

Complex Systems

AGVs are systems requiring planning and integration, which might be a hindrance for smaller warehouses or businesses with very little space. An AGV system also requires technical know-how for installation and operation, which is not always available within companies.

Increased Space Requirements

Lanes, the largest turning radii, and sufficient safety buffers are terms in the vocabulary of AGVs for smooth movements. This could entail very stringent space planning, thereby choking storage density measures in compact-sized warehouses. In such scenarios, balancing AGV paths and storage capacity becomes a challenge for these businesses. There is an intricate planning requirement in future warehouse expansion to accommodate AGV-compatible designs.

Automated Guided Vehicle Integration with Warehouse Systems

AGVs achieve maximum possibilities when they are integrated with other warehouse operations. AGVs, when integrated with warehouse management systems and other computer-based applications, become intelligent tools that work in tune with overall logistics strategies, thus making everything efficient and visible and coordinating even processes flawlessly.

How Integration Works

Integration is all about connecting AGVs with digital warehouse systems so that data and tasks flow smoothly between them. When done correctly, it creates a unified ecosystem where AGVs become an extension of the larger supply chain.

Data Exchange

AGVs provide real-time updates to warehouse management systems (WMS) so that stock levels and item location records are updated. This exchange of information constantly diminishes errors and control of managers with real-time operations.

Task Scheduling

Warehouse systems will automatically schedule tasks for the AGVs so that their activities correlate with new orders, stock movements, and shipping deadlines. This coordination prevents downtime and ensures the system is never underutilised.

Navigation & Safety

Integration of systems will coordinate route planning and AGV movement, reducing congestion and improving safety in the workplace. With centralised oversight, the warehouse management system can allow the prevention of collisions while allowing the optimisation of travel paths for quicker deliveries.

FAQs

1. What is the difference between an Automated Guided Vehicle (AGV) and an Autonomous Mobile Robot (AMR)?

While AGVs stick to their pre-set route following tapes, sensors, or GPS, AMRs are flexible in navigating and can change the routes dynamically using AI. Thus, AMRs are best suited for ever-changing environments, while AGVs are suited for operations conducted in a very rigid setup.

2. How do warehouses determine if they need AGVs?

Labour costs, order volumes, and repetitive tasks are taken into consideration by the average warehouse. If bottlenecks and manual errors occur often, AGVs provide an excellent option. They almost always make the final decision with a cost-benefit analysis.

3. What industries use AGVs outside of warehouses?

AGVs are used to move raw material in manufacturing, supplies in hospitals, baggage in airports, as assembly line support in automotive plants. Their versatility makes them popular across industries that rely on precision and reliability.

4. How long does it take to implement an AGV system in a warehouse?

Depending on warehouse size and system complexity, implementation can take from a few months to over a year, including planning, installation, and staff training. Pilot testing is often recommended before full-scale rollout to avoid disruptions.