AI in the Supply Chain

Supply chain management is being transformed with the advent of artificial intelligence into a further field in which companies forecast demand, move goods, and respond to disruption. Data-driven insight and intelligent automation make operations more resilient while enabling faster decision-making. AI in supply chains exposes inefficiencies unnoticed by normal eyes, thereby giving the organization a proactive stance in taking corrective action.

Further, it helps organizations design supply chains that are not only efficient but also responsive to the sudden onset of unexpected occurrences, be it demand surge or global turmoil. Companies benefit from the AI-powered insights by reducing lead times, optimizing procurement, and ensuring the steady availability of their products-and therefore, employing AI in supply chain operations would bring businesses closer to competing in an ever-fast-moving and uncertain global market.

Technologies involved

The power of AI in supply chain operations comes from the advanced technologies that fuel it. These tools bring intelligence, speed, and precision to processes that were once manual and reactive.

Machine Learning

Machine learning is at the heart of AI for supply chain planning. The algorithms examine past data, recognize patterns, and project demand, inventory, and routes for companies. Unlike traditional models, machine learning improves continuously with new data, so supply chains should be able to adjust to market volatility.

Natural Language Processing (NLP)

The NLP transforms communication across the supply chain. From chatbots updating orders to document processing, NLP ensures that delays are never introduced through manual interpretation. It even tracks customer sentiment so services can be more responsive and planning smarter.

Robotics

Robotics, guided by AI, help in warehouse operations. From autonomous vehicles carrying goods around within distribution centers to robotic arms performing repetitive tasks, robotics serves precision and speed. They also cut workplace hazards, allowing human workers to concentrate on more strategic duties instead of repetitive labor.

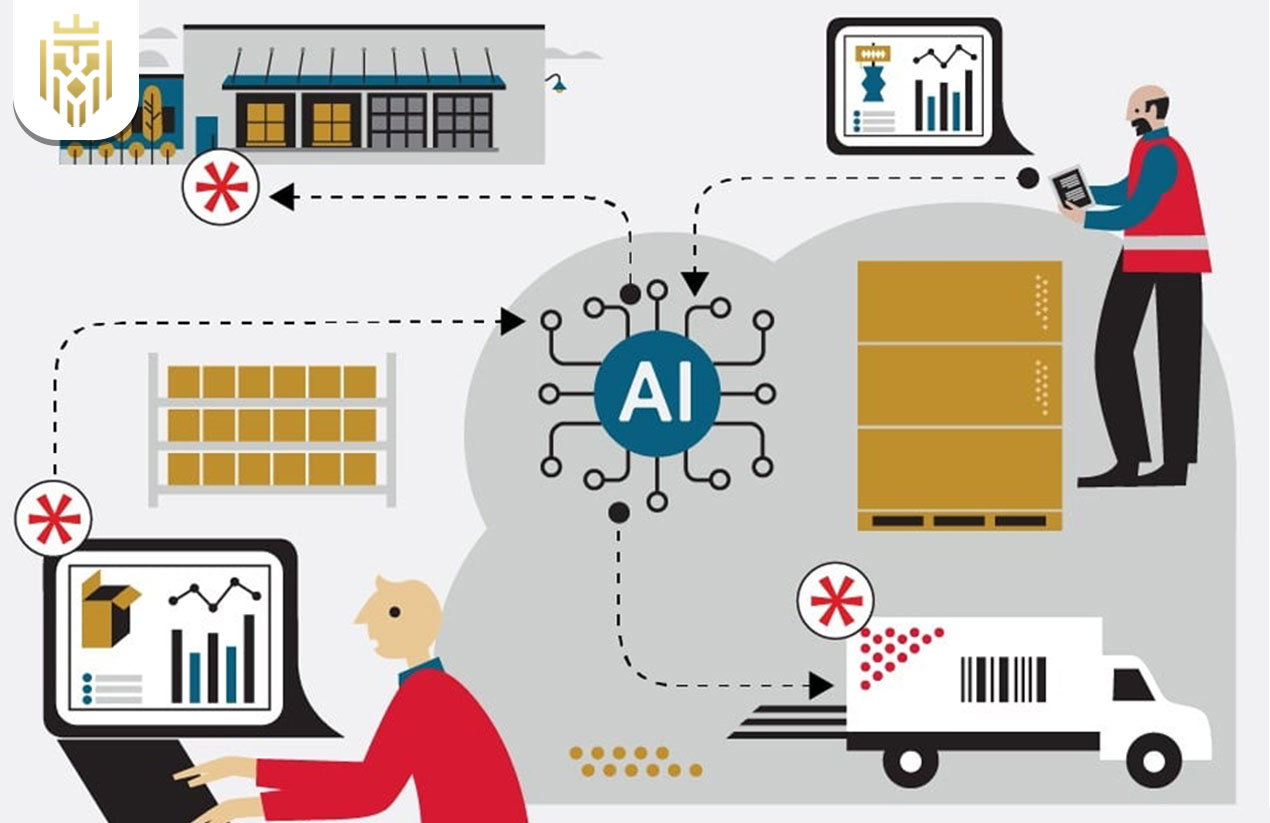

AI in Logistics Operation

The integration of AI in logistics ensures greater visibility, reduced costs, and smarter workflows across every stage of transport and delivery.

Real-time Tracking

AI-enabled real-time tracking of shipments allows businesses and customers to know the exact location and condition of shipments. Predictive alerts on delays and rerouting options mitigate the risk of missed deadlines and improve service reliability.

Smart Logistic Systems

AI-powered smart systems unify data streaming in the from of sensors, IoT devices, and ERP systems. This helps logistics providers maintain smooth operations, preempt disruptions, and coordinate global supply chains with total visibility.

AI in Transport Logistics

In transport logistics, AI revolutionizes the planning of routes and the management of fleets. Based on data compiled on weather, traffic, and fuel consumption, it suggests the best transport options to diminish delivery time, cost, and emissions.

Warehouse Automation

The combination of AI and robotics makes warehouses function with incomparable efficiency. Automated guided vehicles and AI-based picking systems accelerate fulfillment massively, decrease error margin, and maximize space usage, which allows faster customer turnaround.

Freight Management

Freight management benefits from AI through intelligent load planning, contract analysis, and cost estimation. Automated systems balance supply with available capacity, avoiding underutilized resources and preventing costly delays.

AI in Supply Chain Management

AI in supply chain management brings a new level of precision to planning and execution.

AI driven Demand Forecasting

AI-driven forecasting relies on big data to forecast consumer demand more accurately. By accounting for outside factors such as shifting economic trends and seasonal changes, companies are able to avoid stockouts and oversells.

Predictive Analytics

Predictive analytics go further than forecasting by providing information concerning what is going to happen and why. Organizations are able to prepare forums and contingencies to help maintain their own resilience through global uncertainty.

Planning

AI helps balance end-to-end planning from aligning supply to demand and balancing resources across procurement, production, and distribution with little inefficiencies along the way so as to guarantee smooth operations.

Scheduling

Scheduling across plants, warehouses, and transport fleets gets more precise with AI. Changes in demand and resource availability are taken into consideration by the system, which then carries out the scheduling without delays and extra costs.

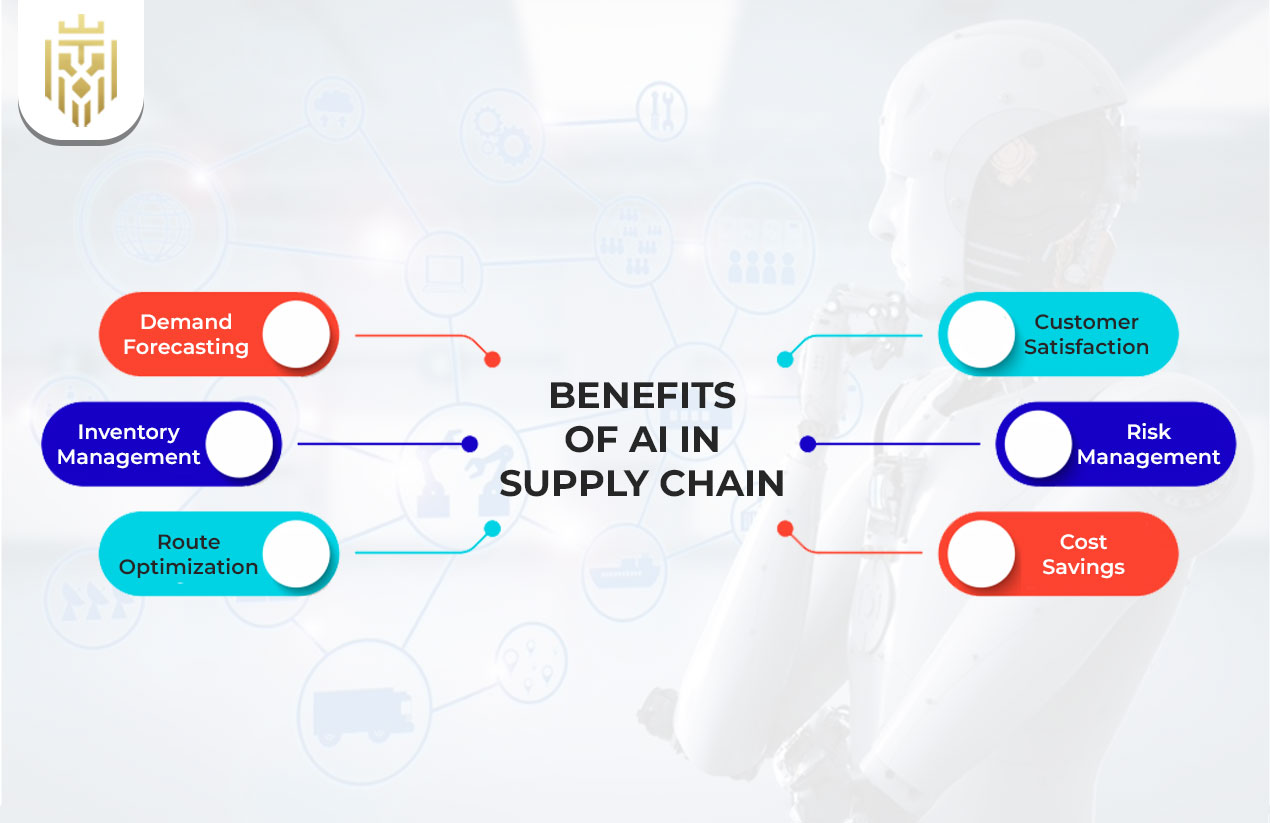

Benefits of AI in Supply Chain

AI offers tangible advantages that go beyond efficiency, transforming the way supply chains function from end to end. By adopting these solutions, companies gain the agility to deliver faster, smarter, and more reliable services.

Demand Forecasting

Accurate demand forecasting ensures that the firm meets customer needs without overstocking. AI advances this process by constantly learning from the ever-changing market trends. This, hence, lets the company always be ahead of consumer expectations as well as quickly adapt to any changes in the market circumstances.

Inventory Management

Artificial intelligence enhances inventory control by ensuring proper stock levels. Automatic alerts guard against shortage or over-storage, thereby reducing wastage of operations. With richer insights, companies may also use inventory with real-time sales trends.

Route Optimization

AI optimizes routes by considering factors such as weather, fuel, traffic conditions, etc. Time and distance reduction leads to delivery precision and lowers emissions. With these dual benefits, the logistics provider gets nice operational efficiency as well as environmental sustainability.

Cost Savings

With the elimination of inefficiencies, AI helps in reducing operational costs significantly. From transportation to warehouse management, automation maintains the best use of the resources available. Savings thus can be channeled into innovation and growth initiatives.

Risk Management

AI enhances risk management by predicting disruptions like supplier delays, geopolitical issues, or natural disasters. Early warnings give businesses time to adjust and protect supply continuity. This proactive approach strengthens overall resilience in the supply chain.

Customer Satisfaction

AI-powered solutions improve delivery reliability, transparency, and responsiveness, creating a seamless experience for customers and strengthening brand trust. Enhanced visibility also fosters confidence, ensuring customers remain loyal to the business.

Differences between Artificial Intelligence & Traditional Software

AI differs from traditional software in that it learns and adapts, unlike static, pre-set instructions. A traditional system acts upon defined precepts, while the advent of data engenders the evolution of artificial intelligence in generating foresights and leveraging workflows with minimum manual interference. This adaptability signifies the deployment of AI in supply chain operations where change is the only constant.

Challenges in Adopting AI

Despite its promise, implementing AI in supply chains is not without hurdles. Businesses must navigate financial, technical, and operational obstacles to fully realize their potential.

Data Quality Issues

Bad data quality can harm AI systems in their effectiveness. Imperfect data leads to wrong conclusions and insights. Different data sources mean different perspectives in different regions or from different partners; AI can hardly hold its value with this. Strong data governance frameworks built to ensure data accuracy and reliability can become gold in this regard.

High Costs

Implementing AI infrastructure and training requires a big upfront cost; thus, small businesses do not have the ability to fast-track adoption of such solutions. Advanced AI platforms also require continuous updates and need skilled professionals to operate them. However, from a long-term view, these costs can be justified by the efficiency and scalability that AI brings in.

Cybersecurity Risks

With AI systems weaving together these huge nets of data, cyber threats will vary only in their diversity and array of methods and means to do damage. It is so much to protect against breaches and misuse. Therefore, an organization must have the greatest security mechanisms in place, implement the strongest encryptions, keep a constant check on its systems, and so forth. Apart from stopping a breach, such measures will help restore customer confidence and build branded equity in the market.

Integration Barriers

Legacy systems often struggle to integrate with AI-driven solutions. Businesses must overcome compatibility issues to fully leverage new technologies. This requires modernizing IT infrastructure and ensuring seamless collaboration across departments. Without proper integration, the true potential of AI remains underutilized.

Scalability Issues

Scaling AI across global supply chains requires significant resources and coordination. Without careful planning, expansion can lead to inconsistent results. Organizations must test AI solutions in smaller pilots before rolling them out widely. Developing flexible, scalable frameworks ensures smoother adoption across diverse regions and supply chain networks.

FAQs

1. What role does AI play in ensuring compliance with international trade regulations?

The AI keeps itself informed on the latest regulatory changes in various jurisdictions and automates compliance checks. This reduces human error, ensures accuracy, and limits further delays arising from manual review.

2. What impact does AI have on workforce safety in warehouses and logistics hubs?

AI-powered robotics and monitoring systems reduce hazardous manual tasks, detect unsafe conditions, and ensure better workplace safety protocols.

3. How do companies measure ROI from AI implementation in supply chain and logistics?

Companies can measure ROI by cost savings through operational efficiency, improvement of delivery timeliness, reduction of errors, and customer satisfaction increment. Long-term benefits are also accounted for by increased resilience and scalability.

4. How does AI integrate with IoT devices to enhance supply chain visibility?

AI collaborates with IoT sensing devices to keep track of shipments, warehouse environmental conditions, and real-time data about goods in transit. This provides end-to-end visibility and a proactive approach to problem-solving throughout the supply chain.