Understanding Carbon Footprint

It is essential to understand what is carbon footprint to assess the contribution of business operations to climate change and greenhouse gases. With detailed carbon footprint analysis, companies can know the sources of their emissions, encourage and enhance energy efficiency, and carry out efficient carbon reduction strategies that facilitate the long-term sustainability objectives in terms of the environment and economic conditions.

Carbon Footprint Scopes

The supply chain carbon footprint is divided into three emission scopes, each of which represents another area of carbon emissions. The knowledge will assist organisations in making accurate environmental impact assessments and a more sustainable supply chain in line with global climate objectives and emission reduction measures.

Scope 1 Emission

The direct carbon emissions that pertain to owned or controlled sources such as manufacturing plants and vehicles are considered as scope 1 emissions. Monitoring them is crucial to proper carbon footprint analysis and to making organisations reduce carbon footprint by optimising energy consumption and cleaner production processes in their premises.

Scope 2 Emission

Scope 2 emissions are indirect emissions of electric power, steam, and heat purchased. Improving energy efficiency and switching to renewable energy significantly helps reduce carbon footprint in supply chain, aligning operations with carbon neutrality and sustainable business objectives.

Scope 3 Emission

Scope 3 emissions are all the other indirect emissions in the supply chain, which are in the form of logistics, product use and disposal of waste. These would be addressed by supply chain transparency and sustainable logistics, which would be significant in assisting in the development of net zero emissions and responsible use of resources.

Why the Supply Chain Carbon Footprint Matters?

Supply chain carbon footprint affects environmental, financial, and reputational concerns of a business. A proper carbon footprint analysis will achieve supply chain sustainability to enhance supply chain compliance, efficiency and carbon reduction programmes to generate ecological and economic gains in the long term.

Regulatory Compliance

It needs to continuously track the carbon footprint data in order to meet the environmental laws and the amount of emissions. Businesses that try to reduce carbon footprint are in line with sustainable business practices, in so far as they help in meeting the net zero carbon emissions goals and ensure adherence to the global standards.

Environmental Responsibility

Minimising carbon emissions will prove to be environmentally responsible. Those organisations that adopt green supply principles reduce the environmental impact, enhance the supply chain sustainability and are crucial in countering climate change by taking the initiative of reducing the amount of emissions.

Competitive Advantage

A low-carbon operation will help to generate consumer confidence and brand loyalty. Businesses that reduce carbon footprint in supply chain gain an edge through sustainable logistics and transparent environmental reporting, appealing to eco-conscious customers and investors.

Risk Mitigation

By measuring the supply chain emissions, one can recognise and prevent such risks as the lack of resources and fines imposed by the authorities. The effective carbon footprint analysis can provide the necessary corrective measures to build the supply chain resilience and uninterrupted business activities in time.

Operational Efficiency and Cost Savings

Energy efficiency strategies and optimisation of logistics can reduce carbon footprint and also minimise operational expenditures. The companies that have focused on the reduction of carbon enjoy better profitability and lower wastage of resources in the supply chain network.

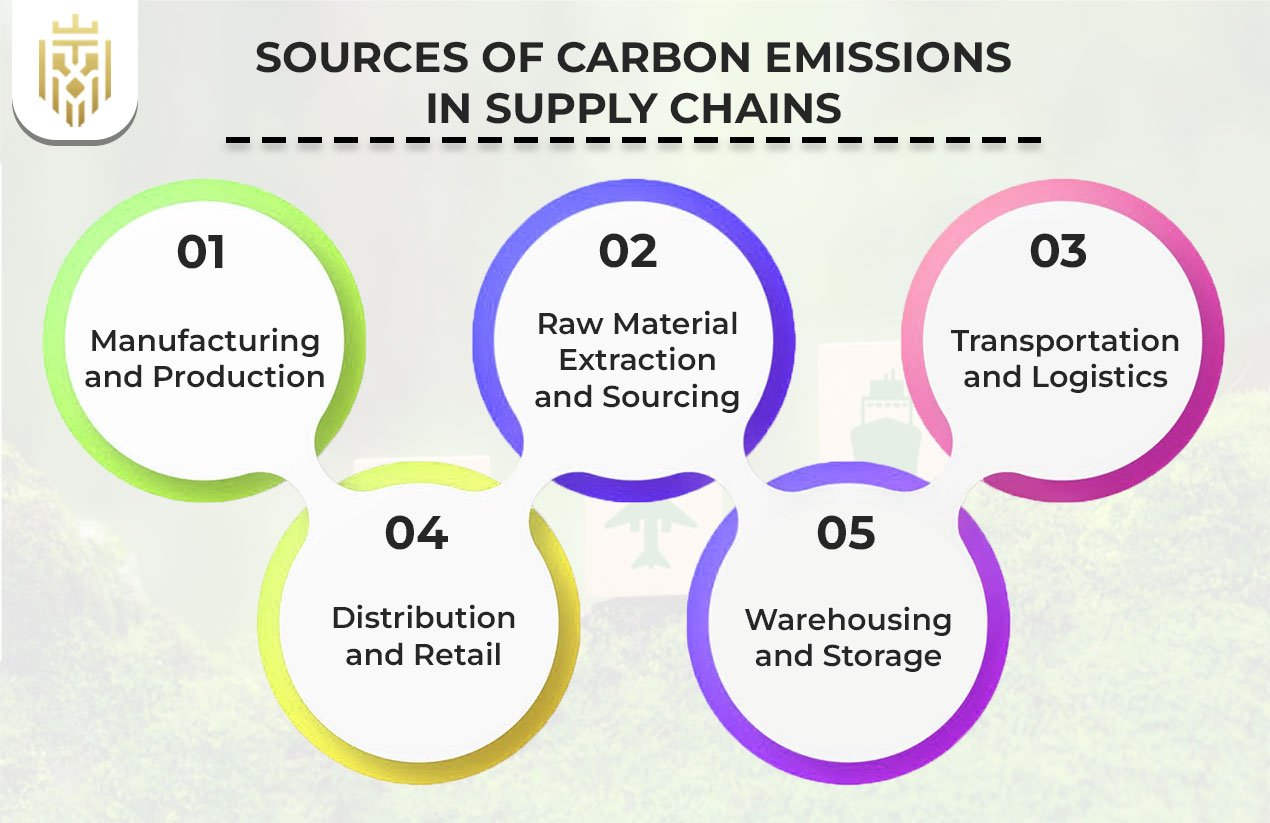

Sources of Carbon Emissions in Supply Chains

It is important that companies seeking to enhance sustainability understand the origins of carbon emissions in the supply chain. Carbon footprint analysis in more detail assists in the understanding of processes that are overly energy intensive or which have a significant emission, giving the opportunity to act on the reduction of emissions and to establish an organisation with a more sustainable supply chain.

Manufacturing and Production

The production processes also produce a high level of greenhouse gases, which is mainly caused by energy usage and the use of fossil fuels. Organisations can curtail the environmental change of production through enhanced energy efficiency and low-carbon operations. Cleaner technologies and sustainable process design are necessary to go through carbon neutrality and ensure long-term sustainability of operation.

Raw Material Extraction and Sourcing

Production of raw materials and their extraction and sourcing usually lead to tremendous carbon emissions as they are mined, refined and transported. Regular environmental impact assessment is useful to enable businesses to know areas to reduce carbon. Collaborating with suppliers who have adopted sustainable business practices also helps the world to attain net zero emissions in industries.

Transportation and Logistics

Transport has continued to be one of the biggest sources of carbon footprint in supply chains due to the high rate of fuel consumption. Companies can reduce carbon footprint in supply chain through route optimisation, sustainable logistics, and shifting to electric or hybrid vehicles. Such practices will reduce the carbon footprint and enhance the performance of corporate sustainability.

Distribution and Retail

The distribution channels and the retailing business create a huge carbon footprint due to energy consumption, packaging and last-mile delivery. The introduction of renewable energy sources and the rationalisation of logistic paths can significantly lower the level of carbon footprint. Green supply strategies are a way of ensuring that the distribution operations are in line with sustainability objectives by the larger supply chain.

Warehousing and Storage

Warehousing also uses energy in lighting, heating and running equipment, which contributes to supply chain emissions. Carbon footprint can be minimised by incorporating energy-saving technologies, including LED lighting and solar power. In the modern warehouses, there are also smart automation systems that analyse carbon footprint and enhance visibility and sustainability in the overall logistic network.

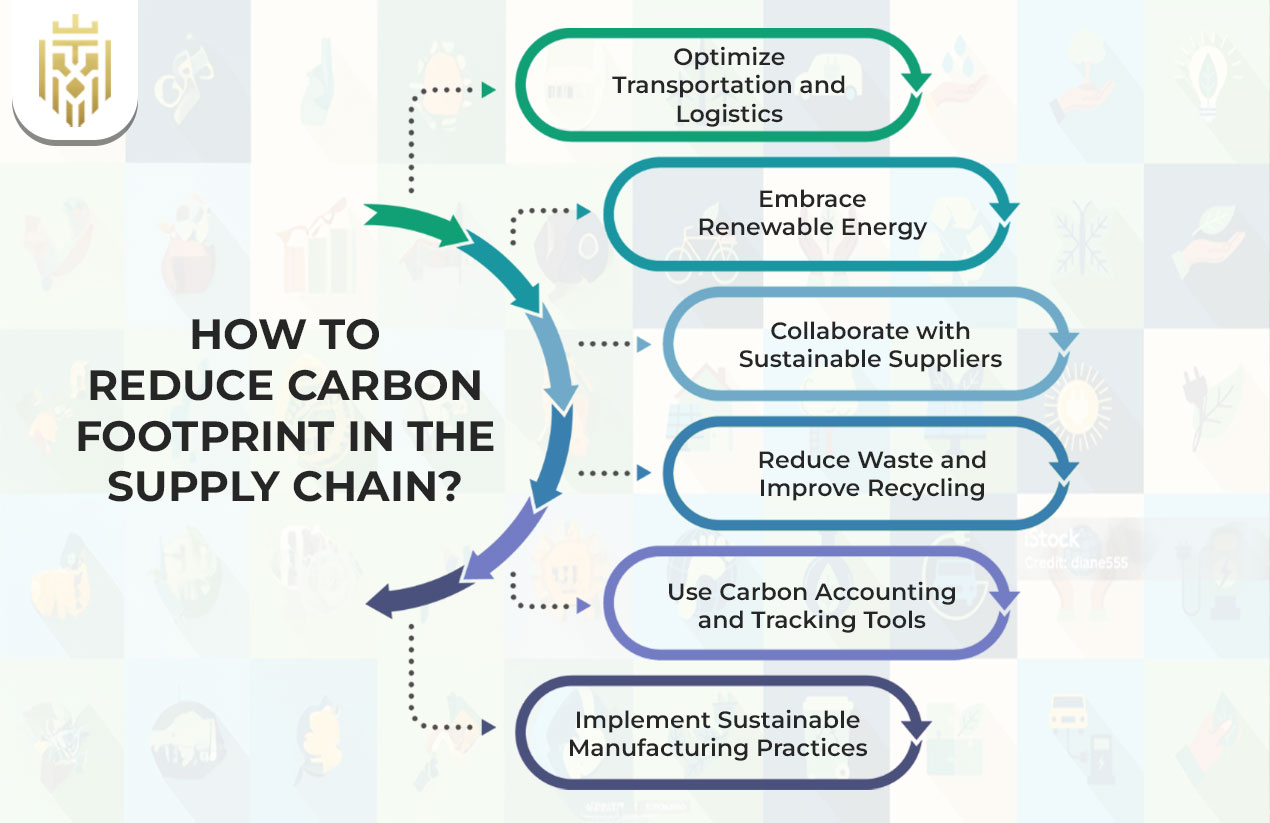

How to Reduce Carbon Footprint in the Supply Chain?

To effectively reduce carbon footprint in supply chain, businesses must integrate sustainability into daily operations. A sustainable supply chain is pushed by strategies such as reduction of emissions, adoption of renewable energy sources and collaboration with suppliers. The aim is to make sure that there are tangible steps for the reduction of the net zero emissions as well as intensifying the level of competitiveness and operational excellence.

Optimize Transportation and Logistics

The maximisation of transportation routes and modes can significantly minimise carbon emissions in world logistics. The electric fleet and low-carbon operations will increase the sustainability of supply chains. Under the management of a logistics network, there is maximum efficiency, and this would enable businesses to lower their carbon footprint whilst ensuring reliability in deliveries and raising their standards of environmental responsibility.

Embrace Renewable Energy

Replacement of fossil fuels with such renewable energy sources as solar and wind decreases the reliance of facilities on fossil fuels. The direct outcome of this transition is the reduction of supply chain carbon footprint and an enhanced commitment to carbon neutrality by a company. Long-term commitment to sustainability, climate responsibility and enhanced environmental performance in business are also evident in clean energy investments.

Collaborate with Sustainable Suppliers

Good relationships with suppliers who are environmentally friendly minimise the supply chain emissions and enhance the end-to-end transparency. Promotion of sustainable business encourages innovation and accountability to one another. Teamwork also allows improved insight into the environmental performance, which would assist organisations to reduce carbon emissions and increase the overall supply chain transparency and supplier alignment in the long run.

Reduce Waste and Improve Recycling

The volume of material waste can be greatly decreased, and recycling rates can be improved, which will greatly reduce the amount of carbon footprint within operations. A circular strategy guarantees reduction of environmental impact and enhanced sustainability of the supply chain. The companies that have committed funds to waste separation and reuse of materials show their interest in ensuring that net zero-emission and resource efficiency are achieved.

Use Carbon Accounting and Tracking Tools

The application of the advanced tools of carbon footprint analysis allows companies to trace the emissions. The real-time environmental impact assessment helps firms to establish major sources of emission and strategise on how to cut down carbon emissions. These are tools that aid in supply chain visibility and tracking of advancement on attainable supply chain carbon footprint reduction goals.

Implement Sustainable Manufacturing Practices

Sustainable manufacturing involves the use of renewable materials, reduction of waste and management of the greenhouse gases. Low-carbon operations can be incorporated into the supply chain to improve its sustainability, and cleaner production means. This initiative will make carbon neutrality an uphill battle and help in the most effective efficiency and long-term investment in a green global manufacturing ecosystem.

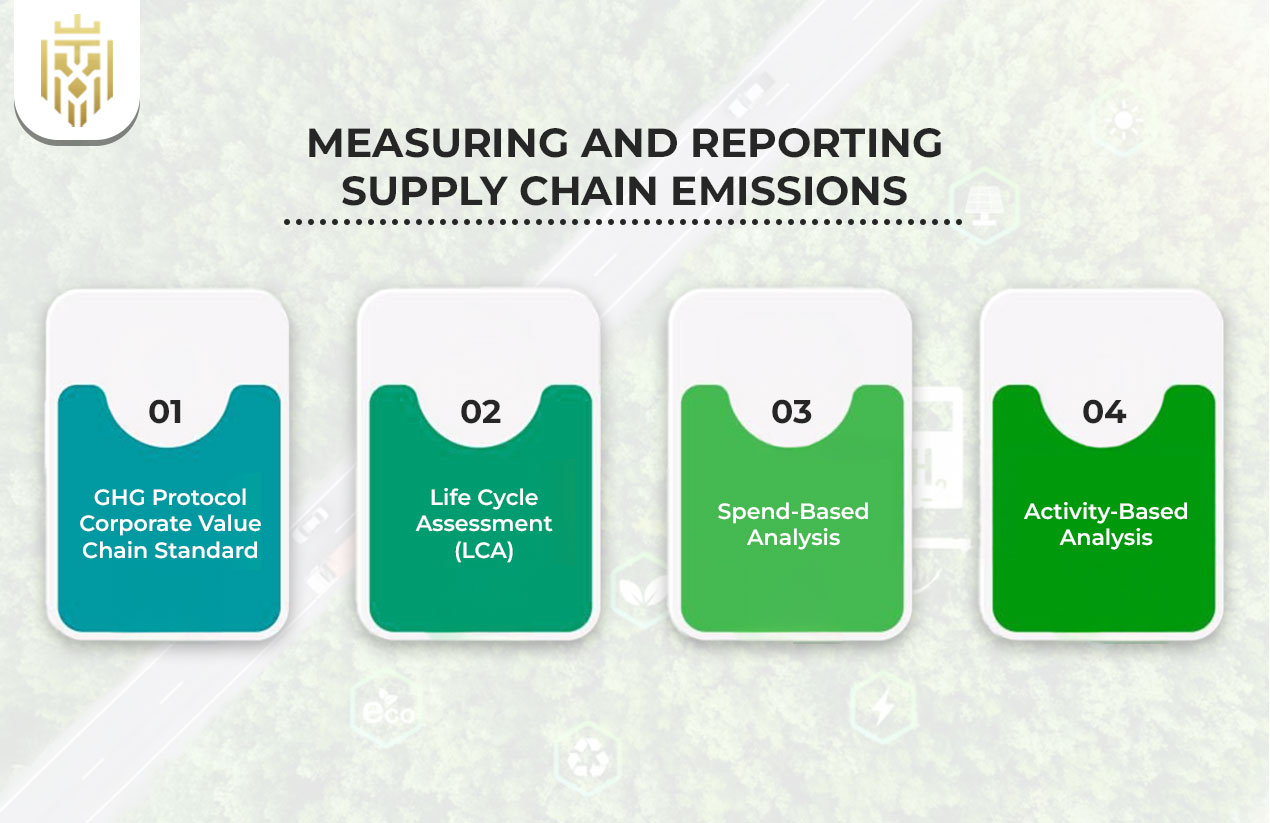

Measuring and Reporting Supply Chain Emissions

Supply chain emissions can be measured and reported to have accountability and constant improvement. Companies conduct a carbon footprint analysis and embrace reporting criteria that enhance transparency of supply chains. This contributes towards credibility, appeals to environmentally minded stakeholders and supports corporate objectives of cutting down emissions and maintaining sustainable supply chains.

GHG Protocol Corporate Value Chain Standard

The GHG Protocol is a universal criterion for measuring carbon footprint of operations. It encourages regular environmental impact evaluation and better reporting of carbon footprint in the supply chains. This framework will facilitate adherence and allow efficient observance of emissions inside and outside the companies.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) is the comparison of all carbon emissions of a product between production and disposal. It helps to maintain supply chain sustainability and find the key areas of reduction of carbon. LCA enables businesses to be aware of their environmental effects, which improves their endeavour to attain net zero emissions.

Spend-Based Analysis

Spend-based analysis estimates the level of emissions through assessing the financial expenditure on a supply chain basis. It is a handy instrument to enable fast analysis of carbon footprint within a situation where there is no more detailed data. The approach gives a wide perspective of carbon emissions that will assist organisations to develop plans to reduce emissions that can be measured.

Activity-Based Analysis

Activity-based analysis concerns quantifying certain operation activities that result in greenhouse gases. It gives granular information on the contributors of carbon footprint, enhancing the transparency of the supply chain. This will aid in proper monitoring and therefore allow evidence-based decision-making on carbon reduction and energy efficiency enhancement in all business operations.

FAQs

1. What is the main difference between operational and supply chain carbon footprints?

The primary distinction is that an operational carbon footprint quantifies the emissions of the suppliers of a company in the direct operations, whereas a supply chain carbon footprint quantifies the emissions of the indirect supply chain of suppliers, logistics, and product lifecycle operations.

2. What role does technology play in reducing supply chain emissions?

With data analytics, carbon footprint analysis, automation, and integration of renewable energy, technology can assist in mitigating supply chain emissions, increasing supply chain transparency, and supporting improved tracking, optimisation, and reduction of supply chain emissions.

3. What industries have the highest supply chain carbon footprints?

The manufacturing, energy, construction, and agriculture industries have the greatest carbon footprint in their supply chain, as they have high carbon emissions, reliance on resources, and greenhouse gases produced during their raw material extraction and supply chain processes.

4. Is achieving a zero-carbon supply chain possible?

Reduction in carbon supply chain with zero-carbon, which is not an easy task, can be achieved through renewable energy, low-carbon operations, sustainable logistics, carbon neutrality programmes and effective partnership with suppliers to achieve long-term carbon reduction and sustainability.

5. What are some common challenges in tracking supply chain carbon footprints?

Some common problems encountered in tracing supply chain carbon footprints are inconsistency in data, supply chain transparency, global networks, inadequate carbon footprint analysis tools, and inability to measure indirect greenhouse gases.