Cross Docking Meaning

The cross docking meaning refers to a logistics technique in which goods are transferred directly to outbound vehicles via inbound transportation with little or no storage. This cross-docking logistics approach minimises warehouse reliance, speeds up shipments, and forms a highly efficient flow of goods through the supply chain.

Types of Cross Docking

Cross docking takes place in various forms, such as pre-distribution cross docking, post-distribution, continuous, consolidation, and deconsolidation. Both approaches facilitate certain logistics requirements. The combination of these models proves the effectiveness of cross docking, which allows companies to streamline their storage, increase efficiency, and solidify their supply chains.

Pre-Distribution Cross Docking

Pre-distribution cross docking is where goods are sorted at the receiving dock based on pre-established customer orders and then finished off. This will simplify cross-docking operations of the warehouse, reduce the handling, and enable faster delivery of orders to customers at a reduced cost of unnecessary stocking in the supply chain management practices.

Post-Distribution Cross Docking

In post-distribution cross docking, goods are temporarily held and then distributed to customer orders. In contrast to pre-distribution cross docking, the approach will give businesses greater flexibility in their decisions, facilitating precise demand projections and a closer fit to market requirements, enhancing the effectiveness of the entire cross docking supply chain strategy.

Continuous Cross Docking

Continuous cross docking is done without interruption to ensure that goods are flowing through the supply chain without delays. This technique works well with fast-moving consumer goods, which reduce costs on holding inventory. Its permanent streamline indicates the benefits of cross docking in contrast to conventional storage, maintaining the process lean and responsive.

Consolidation Cross Docking

Consolidation cross docking involves grouping small consignments of multiple suppliers into one larger shipment to be delivered outbound. This model enhances cross docking within logistics, minimises transportation expenses, and enhances efficiency, and is thus best suited to a retail or manufacturing industry with a large volume of distribution needs.

Deconsolidation Cross Docking

Deconsolidation cross docking separates bulk shipments into smaller loads that are easily distributed regionally. The method assists cost reductions, enhanced last-mile logistics, and enhanced cross-docking in supply chain effectiveness by enhancing flexibility in meeting the varied customer needs at many locations.

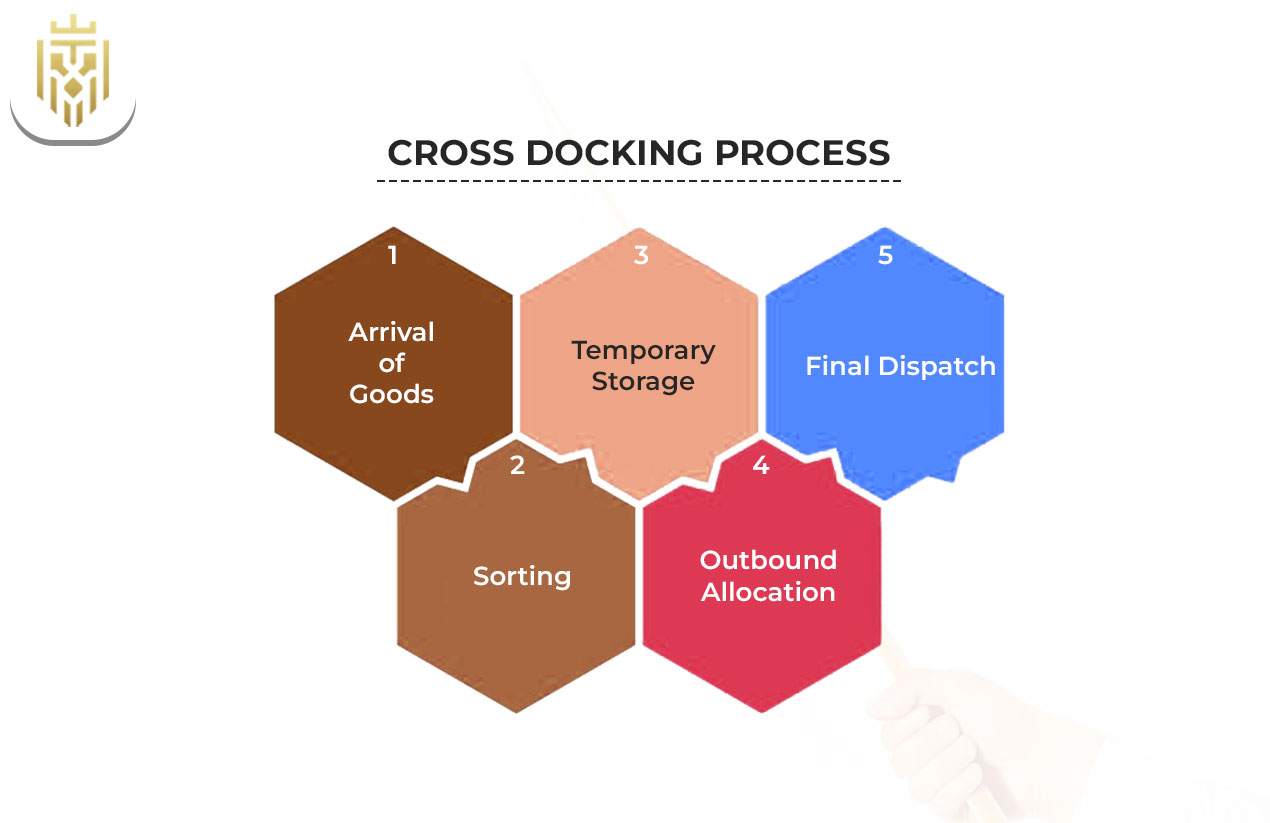

Cross Docking Process

The process steps of cross docking include delivery of goods, sorting, temporary storage where needed, loading, and unloading of the goods. The stages focus on limited handling and storage. This organised flow underscores the benefits of cross docking over the traditional warehousing or distribution methods.

Arrival of Goods

The steps of the cross-docking process begin with the goods arriving at a receiving dock. Inbound goods are unloaded and inspected instantly. Products do not languish in warehouses, as is the case with traditional warehousing, which generates immense time and cost savings.

Sorting

Cross-docking warehouse operations require sorting since the products are arranged according to their final destinations. The step guarantees precision in allotment, lessens misunderstandings, and enables a smooth delivery of orders, which greatly enhances the overall cross-docking logistics plans in contemporary supply chain management.

Temporary Storage

This may be in minimal form and only temporary, as the goods may arrive from the cross-docking process step of being sorted before outbound allocation is available. This measure serves as a buffer to scheduling discrepancies, which will result in a smoother flow and synchronisation between inbound arrival schedules and outbound dispatch schedules.

Outbound Allocation

Outbound allocation assigns products to specific outbound trucks or delivery channels. This necessary step in the cross-docking supply chain strategy will cut down delays, reduce errors, and also make sure that shipments are sent to the customer in the correct location; hence, the approach is better than other traditional distribution methods.

Final Dispatch

The last dispatch stage in cross docking confirms the direct transfer of goods to outbound transport. Businesses achieve shorter order cycles, enhanced efficiency, and the advantages of cross docking as they reduce lead times and increase customer satisfaction by reducing storage time.

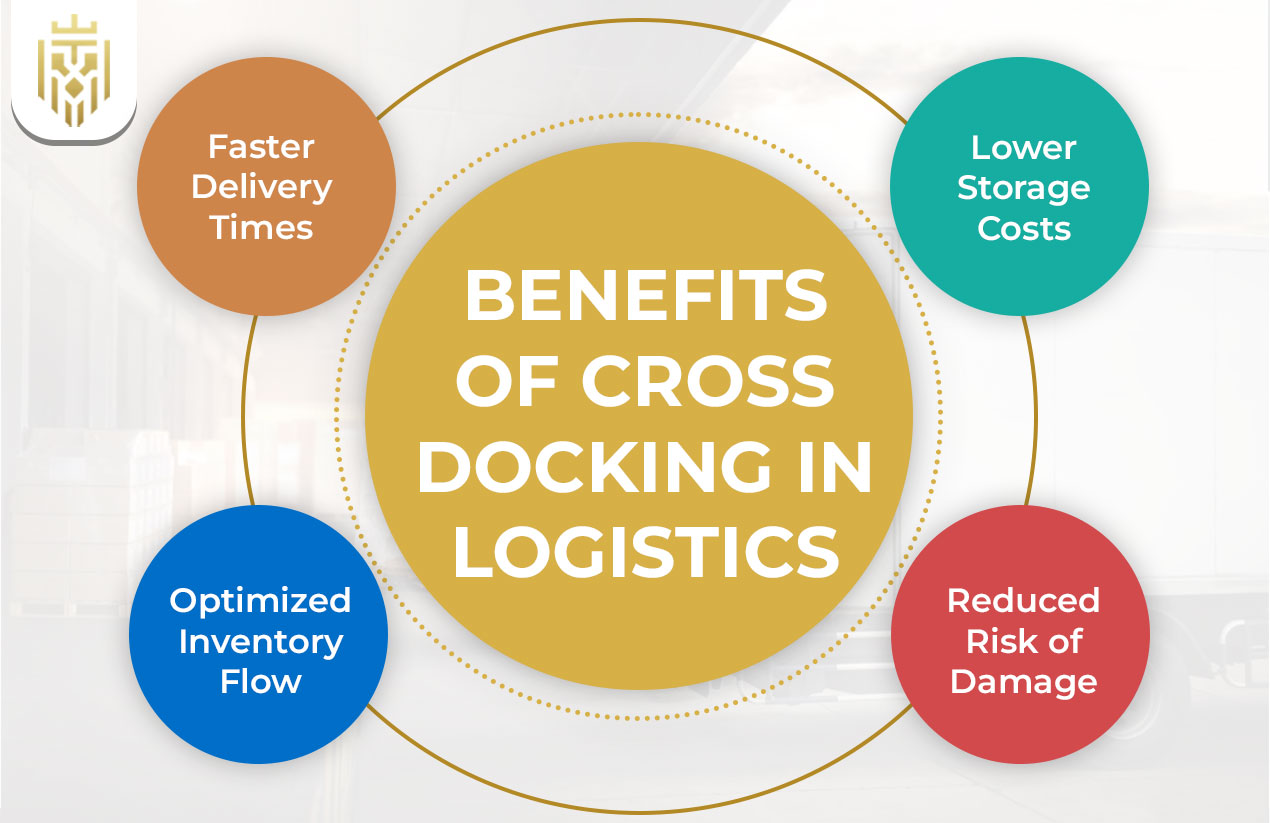

Benefits of Cross Docking in Logistics

Cross docking offers not only higher rates of speed when it comes to deliveries but also low costs, efficient inventory flows, and low damage risks. In comparison to traditional warehousing, cross-docking warehouse operations enhance efficiency, which is in tandem with the customer demand pattern, besides reducing overhead costs. Companies gain high competitive advantages.

Faster Delivery Times

Improved delivery is one of the major advantages of cross docking. The transport mode moves products between modes without going through storage. This translates to shorter lead times, which allows companies to address the expectations of consumers and be responsive compared to the traditional method of warehousing.

Lower Storage Costs

Cross docking reduces storage costs because it reduces warehousing requirements. Businesses save the costs associated with inventory holding, using space as well as management over the long term. It is an illustration of one of the strongest benefits of cross docking to cost-efficient supply chains globally.

Optimized Inventory Flow

Cross docking encourages a more streamlined and efficient flow of inventory. Businesses use cross-docking logistics to keep stock in motion rather than holding stock in big warehouses. The strategy enhances efficiency, reduces capital held in stock, and enhances customer satisfaction rates.

Reduced Risk of Damage

Goods that are processed using the cross-docking logistics are less touched, hence less likely to get damaged. Contrary to the conventional warehousing, handling is minimal, thus resulting in greater quality of the products delivered, which increases reliability, brand image and customer confidence in the supply chain.

Cross Docking in Supply Chain Management

Supply chain management cross-docking minimises dependency on storage facilities and enhances product movement. Lean operations, accelerated flow, and increased responsiveness are beneficial to businesses. This strategic practice makes companies stay competitive and maintain operational efficiency in the global and local distribution networks.

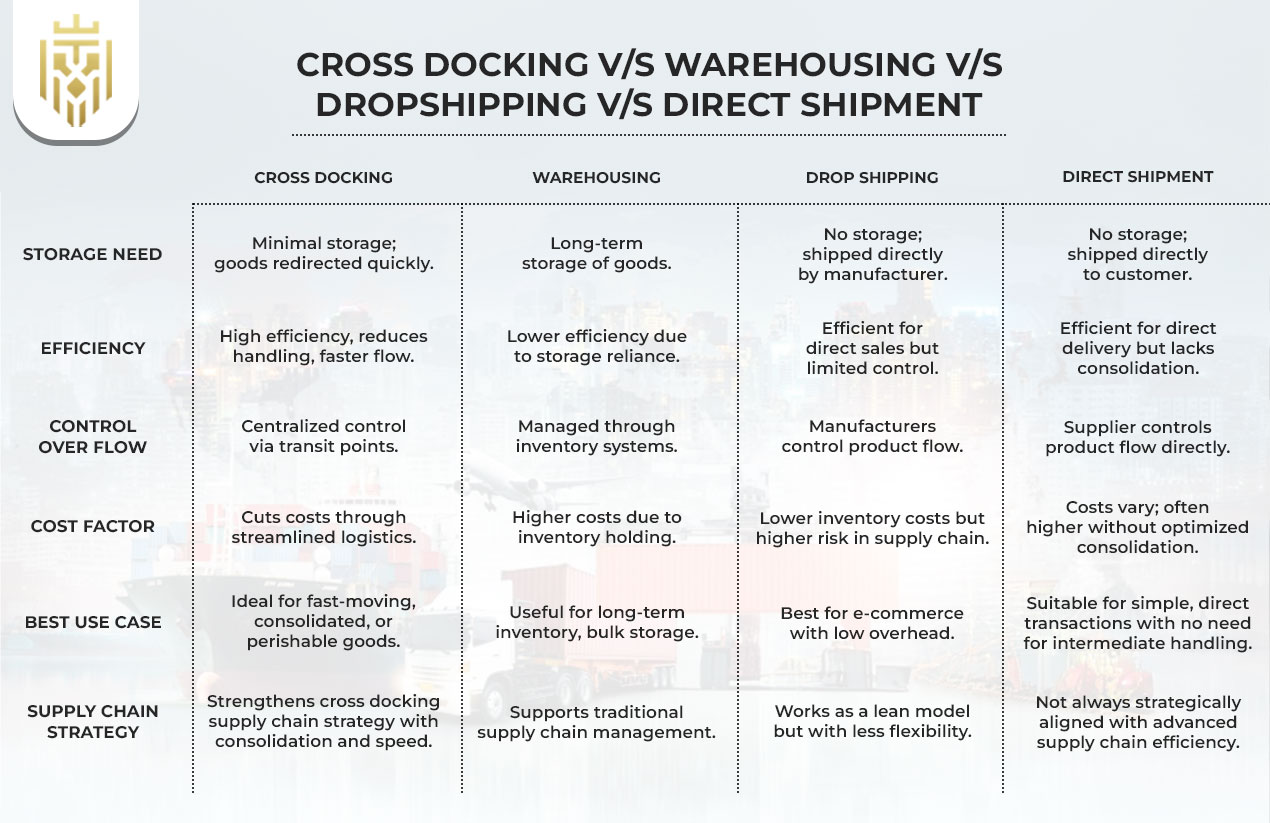

Cross Docking Vs Other Methods

The comparison of cross docking to either conventional storage or alternative models of distribution, such as drop shipping and direct shipment, underscores its benefits. Compared to alternatives, cross docking lowers handling and improves efficiency. These comparisons explain why it has continued to be a popular approach to high-level supply chain management practices.

Cross Docking vs Warehousing

Cross docking and traditional storage show efficiency variations. Cross docking requires minimum storage as it redirects products promptly, whereas warehousing provides long-term storage. This analogy reveals the way business organisations can cut costs, streamline logistics, and improve the overall business performance by moving towards the concept of cross docking.

Cross Docking vs Dropshipping

In comparing cross docking with drop shipping, the distinction is in the product flow control. In drop shipping, goods are shipped directly by manufacturers, whereas in cross docking, goods are first assembled at transit areas. The two methods are distinct in usage, yet cross docking facilitates more effective control of supply chains.

Cross Docking vs Direct Shipment

Cross docking vs direct shipment illustrates that goods can either flow through a facility or directly pass between the supplier and the customer. Cross docking guarantees consolidation, efficiency, and reduced costs, whereas direct shipment is not always optimised and strategically aligned.

When Businesses Use Cross-Docking

Cross docking is applied in businesses dealing with perishables, seasonal products, FMCGs, or temperature-sensitive items. These applications demonstrate the benefits of cross docking, which guarantees speed, freshness, and efficiency. This method is ideal in industries where time is of essence and storage is minimised, unlike other techniques.

Perishable Goods

Cross docking is important to businesses dealing with perishable goods. Given that products such as fruits, vegetables, or dairy products need to be moved fast, cross-docking warehouse activities allow minimisation of spoilage, preservation of freshness, and speed of delivery, thereby being suitable in perishable product supply chains.

Fast Moving Consumer Goods

For fast-moving consumer goods, cross docking enhances rapid replenishment. Constant flow of products means that the supermarkets and retail stores will never be out of stock. This efficiency describes the benefits of cross docking, particularly when customer demand is sensitive and storage delays would adversely affect sales.

Product Requiring Special Environmental Handling

Products that require temperature maintenance, like pharmaceuticals or frozen products, are well suited to the cross-docking supply chain strategy. A decreased dependency on storage means that the goods are kept under controlled conditions during lesser periods, preserving both quality and compliance and facilitating their unproblematic transit to the end-users.

Seasonal or Promotional Goods

Cross docking is commonly practised by retailers in seasonal or promotional products to align with demand bursts. This model reduces the price of storage and ensures agility. Companies utilise the advantages of cross docking in maintaining successful campaigns without excessive investment in temporary warehouse space.

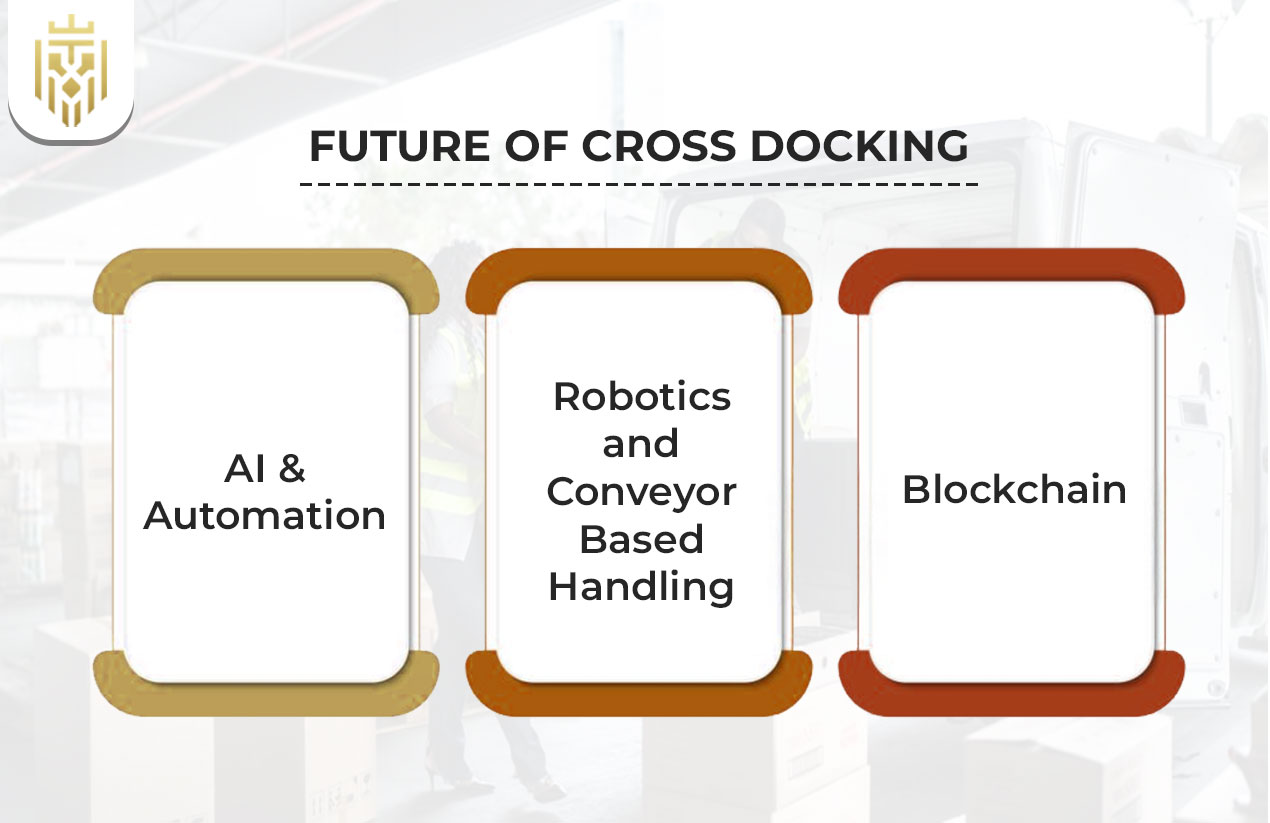

Future of Cross Docking

The future of cross docking integrates AI, robotics, and blockchain into the logistics strategy to guarantee transparency, automation, and speed. These innovations make cross-docking activities in warehouses more scalable and efficient, making cross-docking a core aspect of supply chain management in the future.

AI & Automation

The cross-docking operations in the warehouse are being transformed by AI and automation, which can predict analytics, schedule smarter, and make decisions automatically. These technologies enhance efficiency and precision in product processing and further emphasise the benefits of cross docking in future-orientated supply chains.

Robotics and Conveyor Based Handling

Robotics and conveyor systems will enhance the steps and procedures of cross docking by accelerating the unloading, sorting and loading. This kind of automation minimises mistakes made, lessens human effort and shows how innovation keeps transforming the cross-docking concept of logistics to the efficiency of the world.

Blockchain

Blockchain enhances cross-docking supply chain strategy transparency by ensuring that movements are recorded and authenticity is verified. The innovation minimises fraud, is traceable, and builds trust in logistics networks, which further increases the position of cross docking in sophisticated supply chain management.

FAQs

1) Which Industries Use Cross Docking?

Cross-docking logistics are used in industries such as retail, automotive, pharmaceuticals, and FMCG. Cross docking satisfies the characteristics of the high-demand and fast-moving supply chains that these sectors demand: faster deliveries, less storage, and increased efficiency.

2) Can Cross docking work in international shipping?

Yes, cross docking in supply chain management facilitates international shipping through consolidation of goods, less warehousing, and fewer port delays. It makes trading globally efficient, delivering products across borders smoothly, which reduces the total cost of logistics.

3) Is cross docking suitable for smaller shipments?

Smaller shipments can be supported by cross docking, particularly in the form of consolidation cross docking. Multilevel loads help businesses to save money on transportation and enhance efficiency, which is useful to small and medium-sized enterprises with frequent deliveries.

4) How does cross docking affect the environment?

The benefits of cross docking are environmental. It lowers energy usage and emissions with less storage capacity and less handling. Routes that are optimised and consolidated loads render supply chains greener, which aligns with sustainability objectives.