What is Warehouse Automation All About?

Warehouse automation involves employing technology to minimise human labour in storage, inventory, and distribution. Kinetically powered by fewer and fewer robots, from the control room to the warehouse floor, these automated systems aim to smooth the operation, enhance accuracy, and shorten turnaround times.

What Makes Automation Critical in Warehousing?

Because an untamed, modern supply chain requires speed and precision, automation became crucial. An automated warehouse can be your competitive edge in a rapidly moving marketplace, thereby reducing human error and increasing efficiencies.

How Has Automation Changed Warehouse Workflows?

Automation has transformed warehouses from labour-intensive manual processes to organised technology-driven ones. Tasks that in the past consumed hours of manual labour are now done in a few minutes, allowing workers to engage in more strategic tasks.

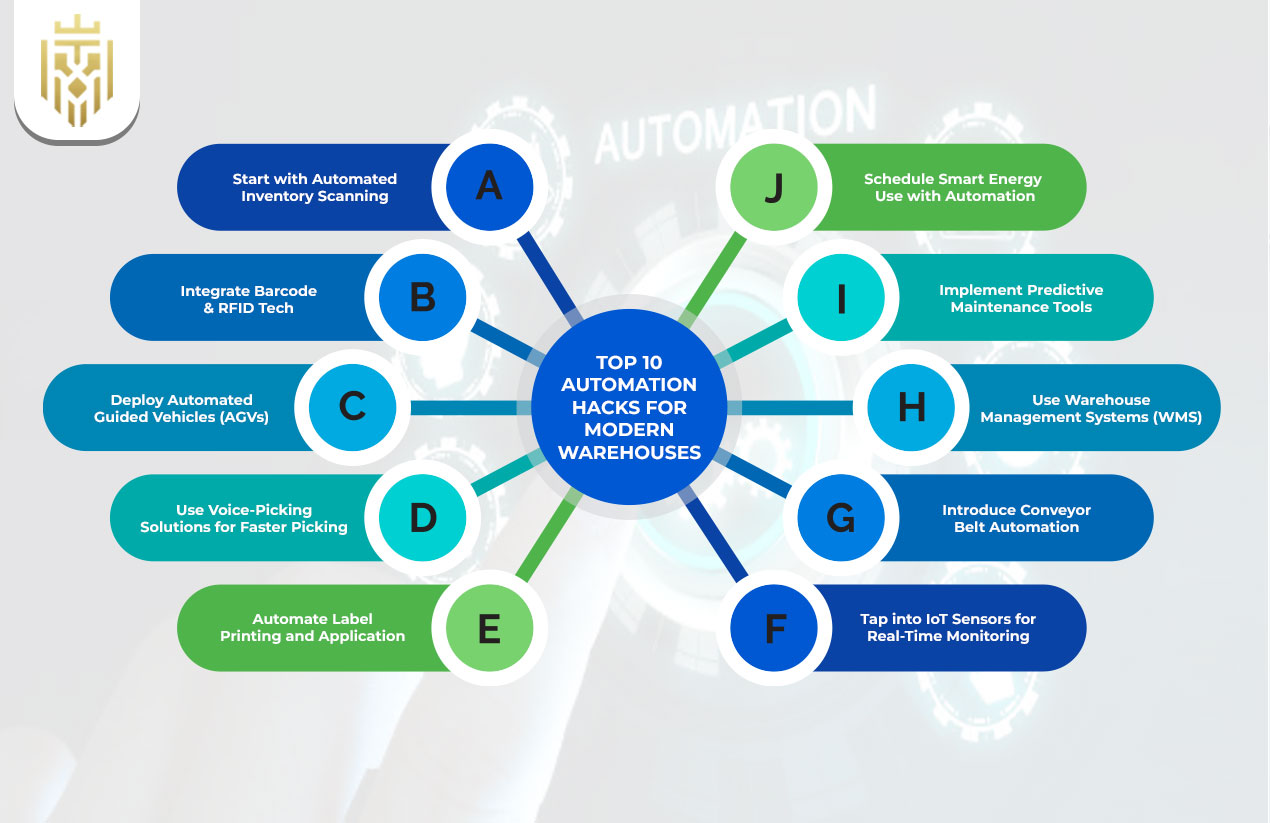

Top 10 Automation Hacks for Modern Warehouses

To stay competitive, warehouses need to embrace smart technology. Given below are ten practical automation hacks that can transform day-to-day operations.

1. Start with Automated Inventory Scanning

It increases accuracy as stock movements are entered into the system in real-time, reducing chances of miscounting and hence providing instant visibility of inventory.

2. Integrate Barcode & RFID Tech

Barcodes and RFID tags smooth the tracking procedure, allowing faster identification of products and reducing human errors. Auditing is also made easier.

3. Deploy Automated Guided Vehicles (AGVs)

These vehicles carry merchandise throughout warehouses with minimum manual labour. They are ideal for carrying out repetitive tasks on set routes, maintaining predefined consistency in product movement, and executing timely delivery.

4. Use Voice-Picking Solutions for Faster Picking

A voice-pick system delivers spoken instructions to workers, speeding up picking and thereby boosting accuracy. By being a hands-free operation, it eliminates delay and increases efficiency.

5. Automate Label Printing and Application

Automated labelling saves workers from arduous manual labelling and provides consistent label application. This also speeds up the packaging process and ensures that the packaging complies with shipping requirements.

6. Tap into IoT Sensors for Real-Time Monitoring

IoT sensors provide real-time monitoring for temperatures, humidity, and equipment performance. They help maintain product quality and predict maintenance requirements before the machines go down.

7. Introduce Conveyor Belt Automation

Conveyors reduce manual lifting and moving of materials and support faster throughput during peak demands.

8. Use Warehouse Management Systems (WMS)

The WMS manages every aspect of the warehouse, from storage to picking and shipping. By centralising operations, it allows managers to track workflows and optimise resources.

9. Implement Predictive Maintenance Tools

Predictive tools use data analytics to identify signs of equipment wear before failures occur, thereby reducing downtime and repair costs.

10. Schedule Smart Energy Use with Automation

Automated systems optimise energy use during off-peak hours, hence reducing operating costs without compromising on the efficiency of warehouse operations.

Bonus Hacks to Push Efficiency Further

Beyond the basics, there are additional strategies that can make warehouses even more efficient. Here are some bonus hacks to elevate performance.

Connect ERP and WMS Platforms

The ERP-WMS integration facilitates the seamless flow of information across operations. This is a step toward improving planning and removing bottlenecks in supply chain visibility.

Use AI for Slotting Optimisation

With AI, slotting assigns products to the most favourable storage location, lowering picking time while raising space utilisation.

Train Staff on Automation Tech Regularly

Training must be regular so that staff is comfortable dealing with automated systems. This leads to better adoption and fewer operational disturbances.

Monitor KPIs with Automation Dashboards

Automated dashboards gather real-time performance indicators such as picking accuracy and order fulfilment rates and present them for managerial review and immediate action.

Use Cloud Storage for Real-Time Data Access

Cloud-based systems allow instant access to warehouse data from anywhere. This strengthens decision-making and keeps global operations connected.

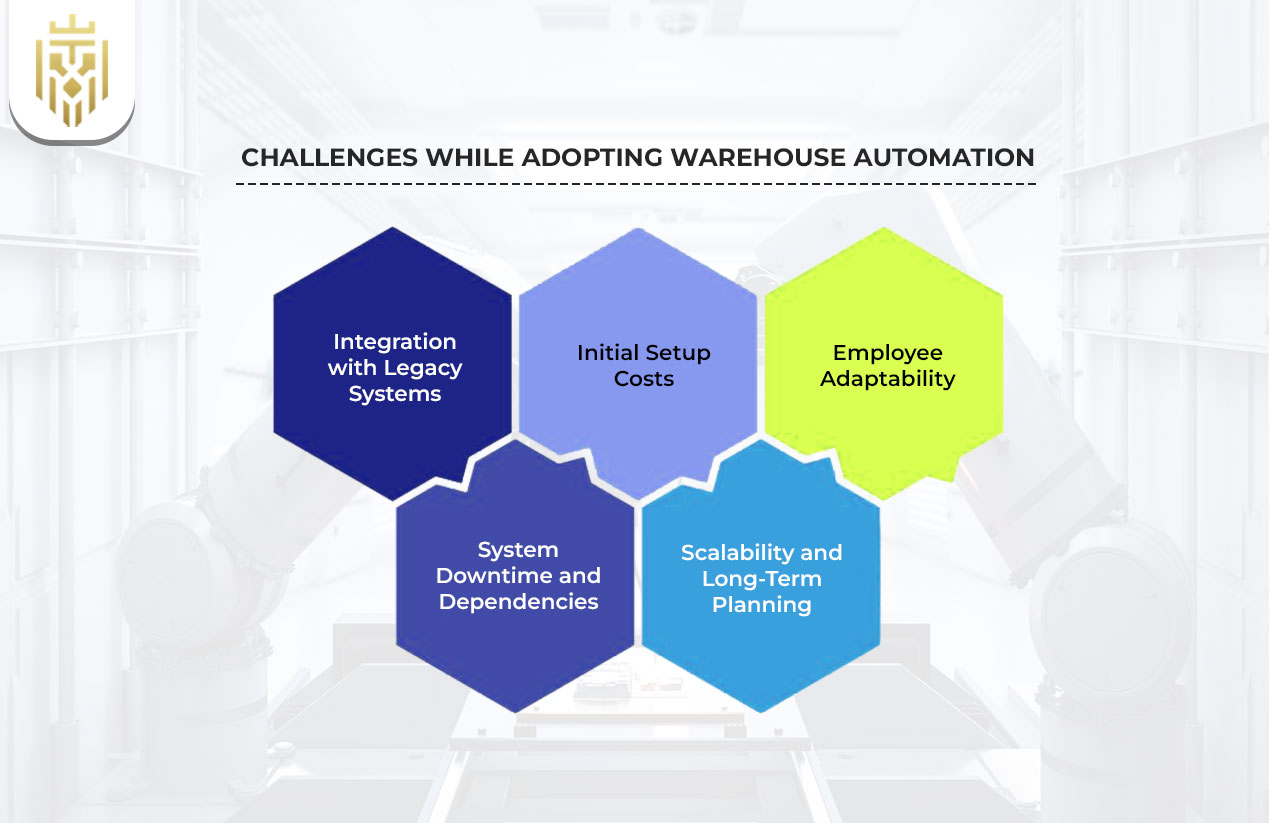

Challenges While Adopting Warehouse Automation

While automation brings many benefits, the journey is not without obstacles. Below are some common challenges businesses face during adoption.

Integration with Legacy Systems

Many warehouses still rely on older systems, which makes the integration task hard. Bridging this gap demands custom-made solutions and meticulous planning.

Initial Setup Costs

Automation technology can require a high upfront investment. The expense, however, is generally justified by long-term savings and efficiency gains.

Employee Adaptability

Employees may be resistant to automation, fearing job loss or simply being unfamiliar with it. Proper training and communication must remain ongoing to tackle this obstacle.

System Downtime and Dependencies

Another problem with automated systems is unexpected downtime that could hamper growing operations. Backup plans and active maintenance can mitigate such risk.

Scalability and Long-Term Planning

System scalability must remain smooth while businesses are growing. This very reason makes it mandatory to go for flexible automation options.

FAQs

1. What is warehouse automation?

Warehouse automation is the use of different technologies and systems to reduce manual processes in inventory, storage, and logistics.

2. What are the top hacks to automate a warehouse?

Some of the effective ones include automated scanning, RFID integrations, conveyor belts, WMS, and predictive maintenance tools.

3. How can automation improve warehouse efficiency?

It improves accuracy while speeding procedures up, allowing a higher possibility of productivity with a greater reduction of errors and costs.

4. What are the challenges of using automation in warehousing?

Limitations include hefty establishment charges, problems of integration in the system, adaptability of the employed, and issues related to downtime.

5. How do I get started with warehouse automation?

Evaluate your warehouse needs first, then go ahead with implementing simple solutions such as automated scanning or WMS while preparing to advance into other heavy-duty tools.