What Is a Smart Warehouse?

A smart warehouse is a warehouse equipped with sophisticated digital systems, robotics, and data analytics that optimise warehouse operations. The modern warehouse definition focuses on the smooth collaboration of automation, AI, and smart warehouse technology so that the workflows are quicker, the errors are fewer, business scalability is better, and the business is in a competitive environment.

How do Smart Warehouses Elevate Business Operations?

By leveraging smart warehouse benefits, companies can reduce order processing time, reduce downtime and increase productivity. Choosing to implement smart warehousing tools to aid in data-driven decision-making can optimise warehouse management and transform operational efficiency to improve customer satisfaction throughout the supply chain.

How Do Smart Warehouses Outperform Traditional Setups?

Smart warehouse technology automates inventory tracking and order fulfilment tasks, unlike manual setups. This enhances accuracy, minimises labour budgets and establishes quantifiable warehousing benefits in terms of leading to faster, leaner and more responsive ongoing customer needs.

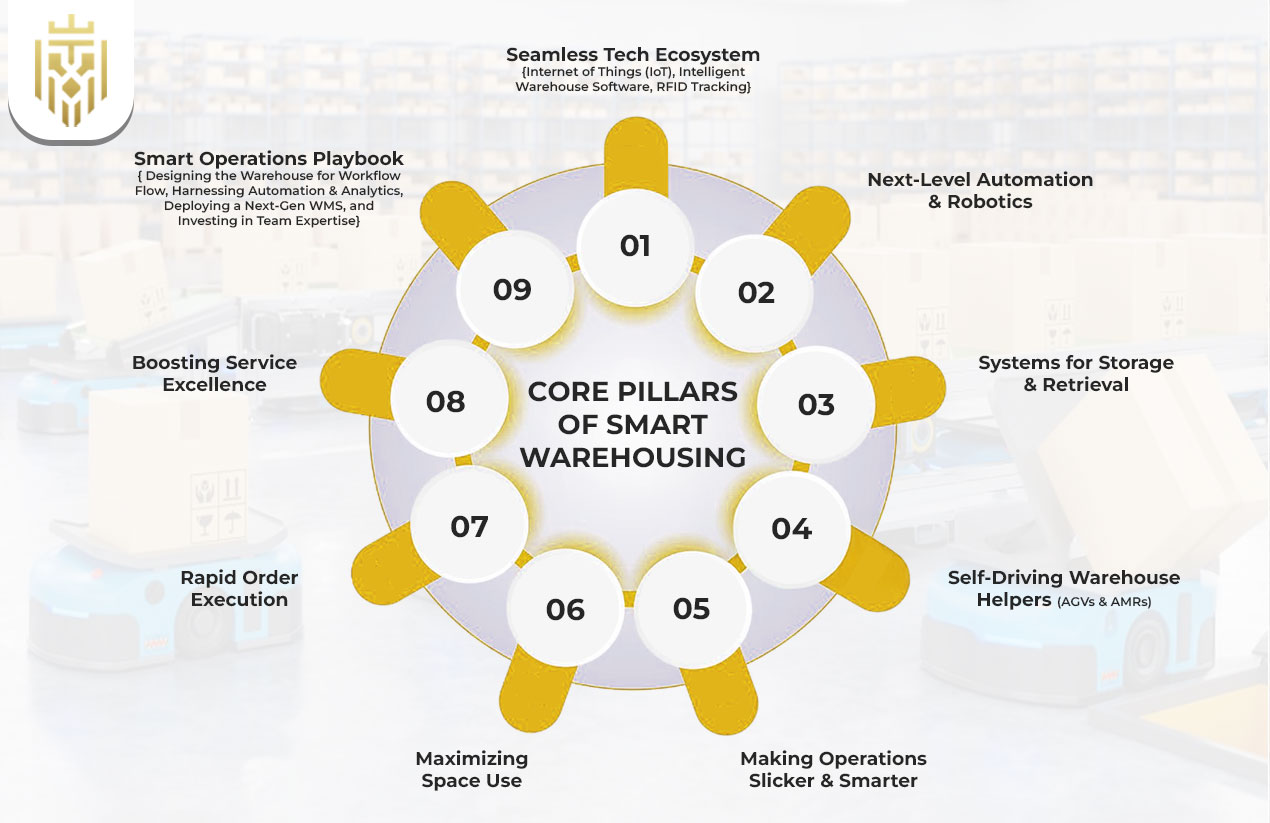

Core Pillars of Smart Warehousing

Smart warehousing thrives on intelligent use of automation, robotics, and software. These pillars play a major role in facilitating effective warehouse operations, a coherently interlinked environment in which information, equipment, and people interact optimally to achieve maximum productivity and sustainable operating growth.

Seamless Tech Ecosystem

A smart warehouse works on interconnected tools and systems. The modular solutions, such as applicant tracking software in staffing and WMS in inventory, offer synchronised workflow, pushing the accuracy of operations and helping businesses to adapt rapidly to the environment in a competitive warehouse.

Internet of Things (IoT)

IoT allows real-time visibility throughout warehouse operations by interlinking devices, sensors, and machinery. This smart warehouse technology maintains accurate inventory control, predictive maintenance, and energy conservation, providing real smart warehouse benefits and securing business logistics in the future.

Intelligent Warehouse Software

Artificial intelligence and state-of-the-art warehouse management tools improve operations and decision-making. Combining the applicant tracking systems to manage workforce efficiency and IoT in inventory control enables companies to gain a competitive advantage in terms of throughput, error reduction, and quick adaptation to the market needs.

RFID Tracking

RFID tracking provides the warehousing benefits through rapid, precise identification of inventory in the warehouses, free of manual checks. It makes inbound and outbound logistics more efficient, reducing errors as well as making it easier to exploit storage space.

Next-Level Automation & Robotics

Robotics and automation in warehouse operations eradicate more manual activities characterised by repetition and instead introduce precision-orientated activities. This results in stable productivity rates, an improved safety profile, and lower operating costs, along with the high quality of service offered to the end customer.

Systems for Storage & Retrieval

Advanced storage and retrieval systems are using smart warehousing technology to best position stocks and also to improve retrieval speed. Conveyors and automated racks minimise picking times, increasing throughput and eliminating manual handling-related errors.

Self-Driving Warehouse Helpers (AGVs & AMRs)

The interaction of self-driving units with smart warehouse benefits is increased by the fact that goods are transported within the warehouse with minimal human control. These automatons operate with dense layouts, handle high volumes of material, and route dynamically, minimising downtimes and freeing up the workforce for more valuable activities.

Making Operations Slicker & Smarter

With intelligent warehouse solutions, companies optimise material moves, selection of orders, and shipment appointments. The use of AI analytics bridges performance gaps, resulting in data-driven results on a long-term goal of outstanding operational efficiency.

Maximising Space Use

Effective layout planning in warehouse management makes the best use of the available storage space and does not affect the efficiency of the workflow. The cutting-edge tracking will guarantee proper placement of goods in ideal areas that reduce retrieval time and maximise daily production.

Rapid Order Execution

Smart warehouse technology, when coupled with automation, allows products to be picked, packed, and shipped in less time. This is vital in delivering on high-commitment deadlines and ensuring the accuracy of orders and customer satisfaction.

Boosting Service Excellence

Businesses with incorporated smart warehousing systems are able to guarantee real-time communications among the sales, inventory, and shipping departments. This alignment enhances customer experience, minimises delays in services, and leads to brand loyalty.

Smart Operations Playbook

The warehouse definition in the digital age extends by encompassing approaches involving unions of automation, analytics, and human savoir-faire. This operations playbook supports perpetual enhancement and flexibility in industry change.

Designing the Warehouse for Workflow Flow

Warehousing benefits are facilitated by a well-planned design through ease of traffic flow, minimising bottlenecks, and enhancing safety. Accessibility and efficiency can be achieved through strategic placement or location of storage zones.

Harnessing Automation & Analytics

The smart warehouse systems use automation and analytics to predict demand, optimise resources, and minimise downtime. These lessons facilitate cost-effective operations that are flexible to future demands.

Deploying a Next‑Gen WMS

Warehouse management under next-gen WMS platforms improves visibility, control, and scalability. These systems are easily compatible with other technologies to provide agility and efficiency in operations.

Investing in Team Expertise

In a smart warehouse, professional employees are also critical. They should train employees in handling automation, interpreting analytics, and safety practices to supplement technology within the team.

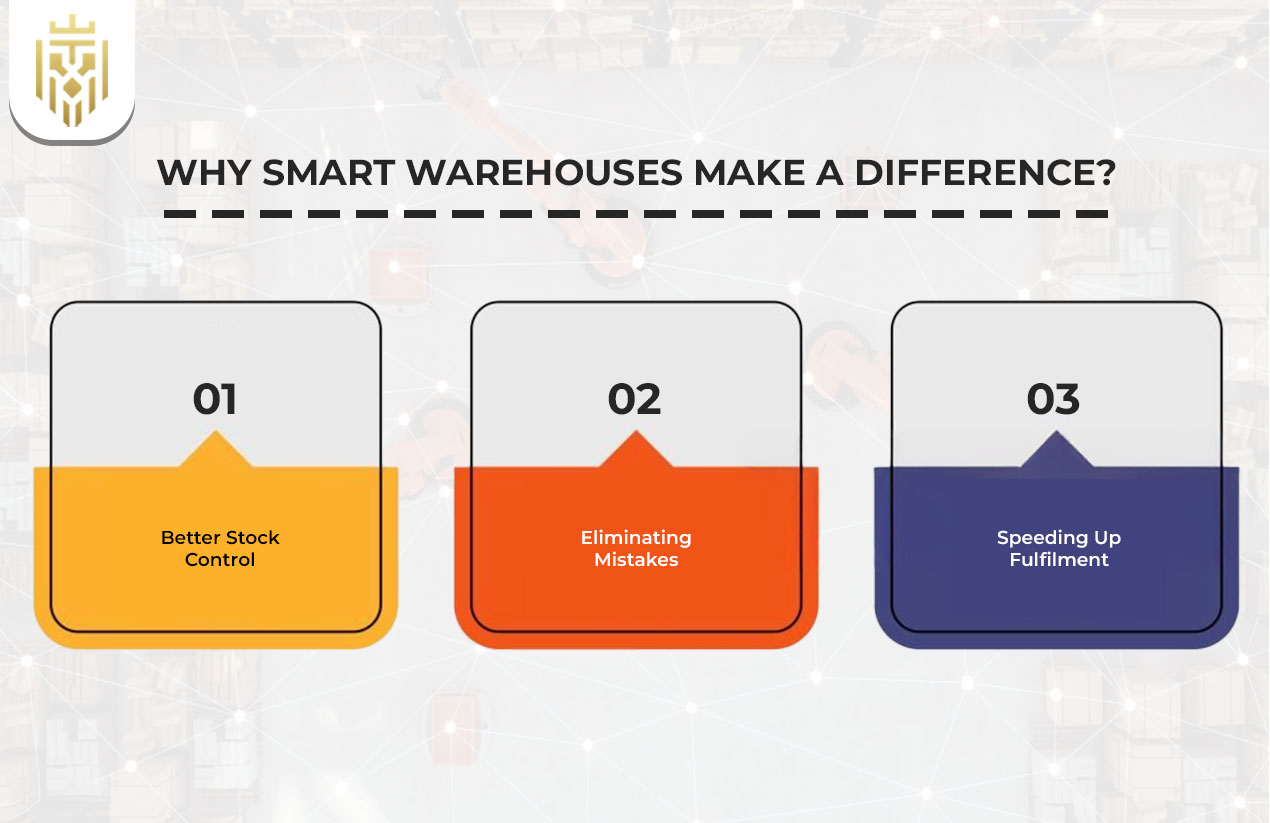

Why Smart Warehouses Make a Difference?

The smart warehouse benefits are evident with an increase in efficiency, the reduction of mistakes, and enhanced scalability. Such systems make logistics proactive, data-driven capabilities that could respond in real-time to changes in demand and market dynamics.

Better Stock Control

Smart warehousing enhances accurate stock through the automation of tracking, instant provision of updates, and predictive inventory management. This minimises stockouts, overstocks and their associated expenses.

Eliminating Mistakes

Businesses reduce human error in picking, packing, and shipping using smart warehouse technology. Automation provides uniformity, leading to better accuracy in orders and consumer confidence.

Speeding Up Fulfilment

Smart warehouse setups with automation, robotics, and AI-powered systems achieve order fulfilment much quicker, assisting businesses to satisfy same-day or next-day shipment demands while upholding high order accuracy and quality.

Frequently Asked Questions (FAQ)

1) What defines a smart warehouse?

A smart warehouse is one that uses automation, data analytics and smart warehouse technology to optimise the operation of a warehouse so that inventory can be managed faster and more accurately than it can be in a traditional storage facility, with greater efficiency.

2) Which features set an intelligent warehouse apart?

Among the core characteristics are IoT connectivity, smart software, robotics, and real-time tracking that can make smart warehousing responsive, scalable, and accurate and guarantee streamlined workflows and limited manual intervention.

3) What makes smart warehouses advantageous?

Smart warehouse advantages encompass enhanced productivity, labour cost reduction, and accuracy, as well as increased order fulfilment speed due to sophisticated automation, prediction of information, and connected systems to simplify warehouse management operations.

4) How are smart and traditional warehouses different?

Smart warehouses are smarter than traditional warehouses due to automation, the ability to quickly access or share real-time data, and IoT tracking solutions, which provide greater precision, faster speeds, and efficiency, in contrast to a conventional warehouse, which is dominated by manual processes and is slow.