What is First Mile Delivery?

First-mile delivery is the initial stage of transporting goods from a manufacturer or supplier to the nearest supply chain stage, typically a warehouse or distribution hub. When it comes to quickening the pace, increasing precision, and increasing the efficiency of supplies in general, knowing what first-mile delivery is important.

What is First Mile Logistics?

First-mile logistics concerns the movement and control of products immediately after manufacturing. This phase requires meticulous coordination so that the dispatch happens at the right time and without causing any hitches with other parts of the delivery routine, and this directly influences the efficiency and customer satisfaction in the supply chain functions.

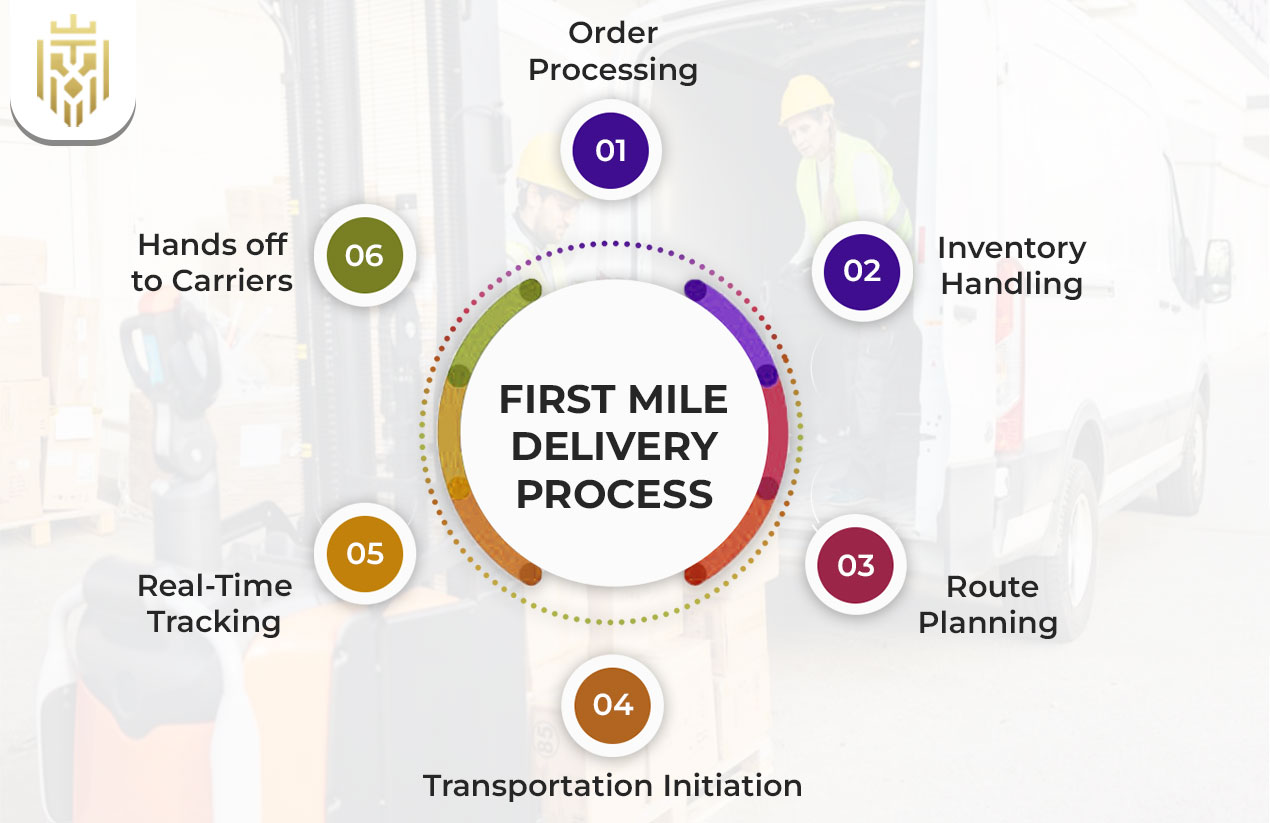

First Mile Delivery Process

The first-mile delivery process comprises several steps: order processing, packing, transportation organising, and carrier scheduling. All the steps are crucial in facilitating the movement of goods between the source point and the next milestone in the middle of the chain of mile delivery.

Order Processing

The initial stage of the delivery process is order processing: the request for purchasing is received and confirmed, the availability of the products is verified, and the shipping documents are created. The accuracy here creates effective first-mile delivery services that minimise mistakes and delays when the product reaches further along the supply chain.

Inventory Handling

Inventory handling includes preparation, sorting, and organisation of products to be shipped. Smart first-mile management can achieve order accuracy, reduce the risk of damage to goods, and give assurance that goods are prepared to deliver to the customer and business with quick dispatch times that keep up with customer and business delivery commitments.

Route Planning

Mile delivery includes route planning, which determines the fastest and most economical way to deliver goods. Optimising delivery routes in the first mile allows businesses to save on fuel, enhance timelines, and deliver the shipment to the next step without any unnecessary delays.

Transportation Initiation

The beginning of transportation is when goods leave the supplier or the production point. This first-mile delivery step guarantees that the shipment is loaded properly and that it ships at the right time and is aligned to schedules to sustain the overall efficiency of the delivery process throughout the supply chain.

Real-Time Tracking

Access to shipment movement through real-time first-mile monitoring provides insight into issues that can be solved in advance. The tracking technology helps businesses to be transparent, maintain quick action times, and navigate the last mile of the supply chain.

Hands off to Carriers

First-mile delivery ends with the transfer of products to carriers who transmit them to the logistic providers. The precision at this point will make the shipment transition into the last mile phase, where customers get final delivery.

What is the Role of First Mile Delivery in the Supply Chain?

First-mile delivery in the supply chain has the responsibility of serving as a foundation of efficiency. It also affects cost, delivery time, and product quality, which makes it a critical step before goods are subjected to mid-mile or last-mile delivery services.

What are the differences between first mile delivery and last mile delivery?

The key distinction between first-mile delivery and last-mile delivery is the point in the supply chain they occupy. Although the first mile involves transporting goods between production and distribution, the last mile concerns transporting them to the final customer.

Components of First Mile Delivery

The elements of first-mile delivery are packaging, efficient routing, real-time tracking, inventory management, labelling, and carrier coordination. Each part makes sure that goods pass through the origin into the next phase of the delivery process at the right speed, with accuracy and efficiency of the supply chain.

Packaging

First-mile delivery involves packaging of the merchandise to ensure safety in transit. Rugged, durable packaging minimises risk of damage and compliance requirements and facilitates continuity through all segments of the delivery channel, from manufacturer to distribution centre.

Efficient Routing

First-mile delivery points to efficient routing services that minimise the operational costs and delays. The increased timeliness of delivery planning of the best routes possible for shipments enables companies to operate smoothly through their supply chain to the final destinations.

Real-Time Tracking

Tracking in real time promotes transparency in the delivery of the miles since it enables suppliers and the shipper to track the movements extensively. This visibility can help in addressing problems promptly, as well as ensuring on-time arrival before goods reach mid-mile and last-mile sections.

Inventory Management Systems

The first-mile delivery is facilitated by the inventory management systems through real-time records of stock. They are used to prevent overstocking or stockouts and can facilitate order fulfilment more coherently and keep the consistency of the overall delivery process.

Labelling & Documentation

First-mile efficiency requires accurate labelling and documentation. Appropriate documentation makes it possible to respect regulations, facilitates the flow of goods in terms of customs clearance when it is necessary and makes the movement of goods to the next step of the supply chain a lot more efficient.

Carrier Coordination

Carrier coordination facilitates the smooth operation of the first-mile delivery services in collaboration with transport providers. The communication should be clear, scheduling should be timely, and updates in real time help to prevent delays and to make the transition between the first mile and subsequent phases of deliveries seamless.

Challenges of First Mile Delivery

Monitoring and packaging, packaging errors, labelling difficulties, and increases in delivery costs are the primary issues of first-mile delivery. Any factor may affect the delivery process negatively, adding to inefficiencies and influencing how goods are moved between production and mid-mile or last-mile delivery steps.

Tracking Limitations

The lack of shipment visibility leads to delays and loss of updates because of tracking limitations in the first mile. Businesses without well-implemented real-time systems are characterised by inefficiencies that spill to the mid-mile and last-mile processes, thus leading to difficulty in having a consistent delivery schedule.

Packaging

Poor packaging during mile delivery may result in damage to the goods before they reach the distributing centres. The importance of setting high packaging standards in the first mile delivery process is to safeguard goods, minimise returns, and simplify the transition towards other stages of supply chains.

Labelling Errors

Labelling inaccuracies can slow the delivery process, routing shipments to the wrong destinations and halting shipments at checkpoints. Strong operational complexity arises through inaccurate information when the first mile services are delivered to the customers, which may cost credibility in case of unsuccessful transportation of goods, either due to delay or delivery at the wrong place.

Route Planning

Poor route scheduling by the first-mile delivery leads to increased transportation and delays in delivery. In the absence of optimised routes, businesses are wasting resources and are at risk of missing deadlines, which impacts the supply of goods to the mid-mile and last-mile delivery stages.

Operational Cost

In costs, first-mile delivery services are characterised by high operation costs due to fuel consumption, labour costs and handling inefficiencies. These costs, in the absence of cost-control strategies, can have an influence over the entire delivery process, which will financially impact the competitiveness and profit margins of a fast-paced market.

Manual Coordination & Poor Integration

In the first mile operations, manual coordination slows down the processes and makes them susceptible to errors. Weak system integration may stall the delivery process, slowing goods until they are transferred to the mid-mile or last mile of delivery.

First Mile Delivery Optimisation

Through route optimisation and the defence of first-mile delivery services, goods arrive at their next traffic circle as per schedule. The advanced mapping tools offer cost savings and efficiency for drivers and the ability to deliver on schedule, contributing overall to making the delivery of miles better.

Route Planning and Optimisation

Warehouse management also contributes to first-mile operations by facilitating inventory management, curbing delays, and speeding up dispatch. Ordered storage and optimised workflow contribute to the speed and reliability of the delivery process before departing for mid-mile or last-mile phases.

Efficient Warehouse Management

Warehouse efficiency makes first-mile processes more effective; it enhances the processing of inventories and minimises delays to further facilitate faster dispatch. Before transitioning to mid-mile or last-mile operations, sorting and efficient workflows are used to ensure speed and consistency of the delivery process.

Labelling

When first-mile delivery is appropriately labelled, there is minimal shipment error and a smooth transition between stages of transportation. The delivery process is crucially reliant on this step, as it enables the shipment of goods to distribution centres or retail stores without additional delays and incorrect routing.

Logistics Management

Good logistics management guarantees that the first-mile real-time delivery is streamlined between pick and dispatch. While organising suppliers, carriers, and inventory handling, companies can keep a stable delivery system running and limit supply chain flow disturbances.

Proof of Delivery

In mile delivery, evidence of delivery confirms that products have reached the next destination. This step in first-mile delivery promotes accountability, enhances record-keeping and aids in maintaining trust throughout the supply chain before entering other stages.

Strategic Sourcing and Supplier Management

First-mile delivery Strategic sourcing provides quality assurance and timely delivery of the suppliers. Effective supplier management assists in the delivery process, ensuring consistency of operations and an easier transition to mid-mile and last-mile phases of delivery.

Automation & Technology Integration

In first-mile delivery services, automation limits manual errors, accelerates processing, and increases tracking. Technology systems are all integrated to improve the delivery process, enabling shipments to flow effectively to the next step with few interruptions or delays.

Sustainability and Carbon Reduction

First-mile delivery practices are sustainable and encourage the reduction of fuel consumption and carbon emissions. Biodegradable packaging, route optimisation, and efficient work impede the environmentally responsible delivery process but keep the speed and reliability.

Supplier Collaboration & Data Sharing

The cooperation of suppliers in the first-mile activities enhances transparency and shipment planning. Live data sharing can make the delivery process smoother, allowing easier responses to problems and allowing goods to be transported to the mid-mile and last-mile delivery easier and faster.

FAQs

1) What defines first‑mile delivery?

First mile delivery refers to the transport of a product initially from a manufacturer or supplier to a warehouse or distribution centre, which would then be the first leg of the larger delivery process.

2) Why is first‑mile delivery significant in logistics?

Supply chain efficiency begins with first-mile delivery. Misfires or delays at this point will be propagated downstream to mid-mile operations and will slow delivery to customers in the final mile.

3) How does the first mile influence last-mile performance?

By properly managing the first mile, you are guaranteed timely deliveries to distribution points that will minimise bottlenecks and make the last mile delivery smoother, which will improve efficiency, accuracy, and customer satisfaction throughout the entire logistics process.

4) Which technologies support optimisation of the first mile?

First-mile delivery services may enable route optimisation software, real-time tracking, automated inventory systems, and forecasting based on AI technology that help to streamline operations and optimise the entire mile delivery performance.

5) What role do packaging and labelling play in the first mile?

Good packaging in the first mile of delivery helps secure goods during transportation, and the use of adequate labelling adequately avoids mistakes during transmission, such as misdelivery, and enhances efficiency in the entire delivery.

6) What are common cost pressures in first‑mile delivery?

In first-mile delivery, the cost of fuel, the cost of labour, and inefficient routing increase operational costs. When not optimised, these have severe effects on profitability and overall supply chain performance.

7) How to select a reliable first‑mile logistics provider?

Select first-mile delivery services that have a good tracking system, effective routing solutions, a proven track record, and the availability of integration solutions to help transition more smoothly to mid-mile and end-mile phases of the supply chain operations.