What Is a Lean Supply Chain?

A lean supply chain is aimed at eliminating waste and, at the same time, maximising customer value. When understanding what a lean supply chain is, know it to be a reduced method of supply chain management that raises effectiveness, responsiveness, and quality of all supply chains.

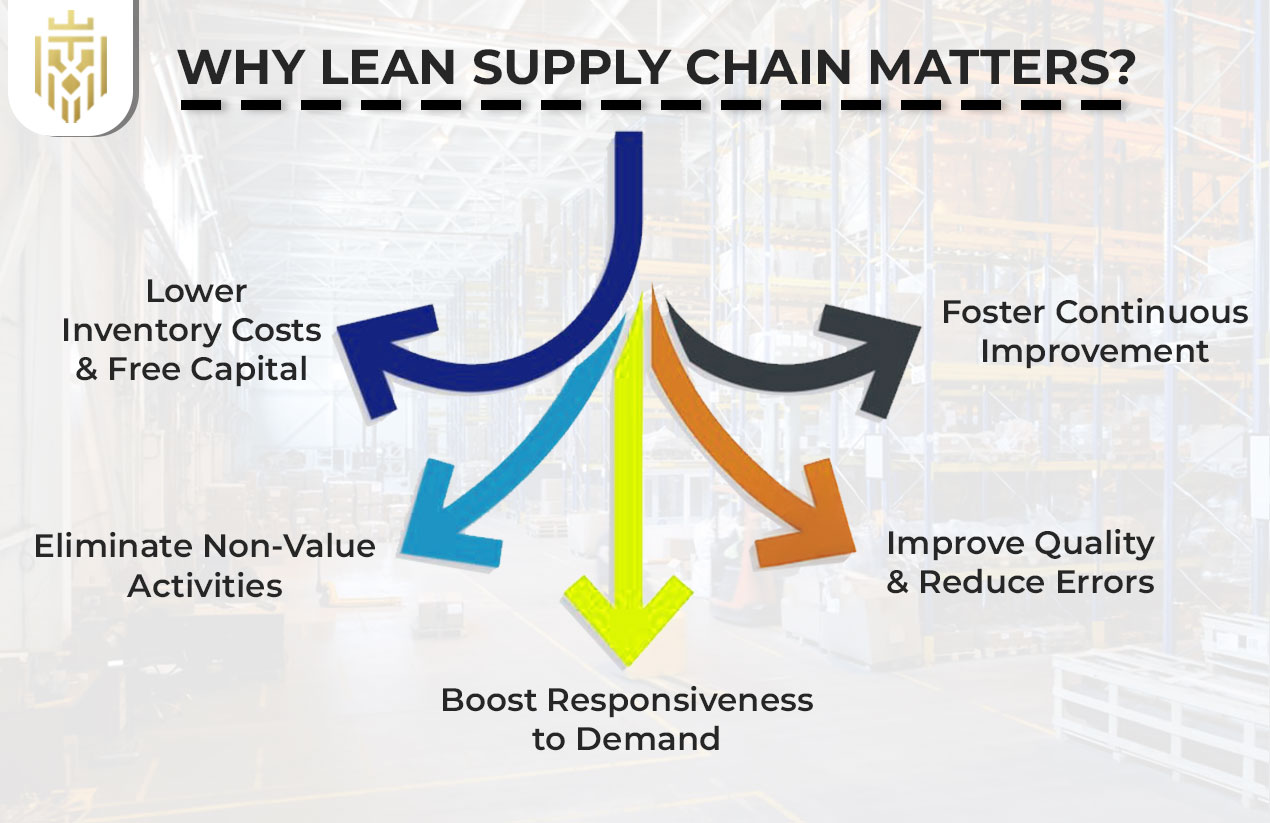

Why Lean Supply Chain Matters?

Implementing the strategy of lean supply chain management will help companies to minimise wasteful expenditures, increase flexibility, and enhance future performance. The lean principles help businesses to become highly competitive in the respective markets since they are optimised to keep up with the activities in supplying their services and products.

Lower Inventory Costs & Free Capital

Companies can save considerable expenditures on inventory holding by using improved forecasting and lean supply methods. Proper control of a chain results in the ordering and storage of the materials only when required, and this helps in releasing the capital used in making other important investments in business and increases efficiency of the cash flow.

Eliminate Non-Value Activities

Lean SCM focuses on the elimination of activities of no value addition to the customers. Enterprises able to learn lean ways to work will be able to organise the workflow, decrease the lead time, and do the processes more effectively to make a smooth situation, but also minimise waste in the supply chain.

Boost Responsiveness to Demand

A lean supply chain approach helps a company to meet the dynamic customer requirements promptly. Organisational change toward production integration with the market confers adaptability to organisational trends and ensures product availability without overstocking, thereby producing more balanced operations with efficiency.

Improve Quality & Reduce Errors

Applying lean supply chain management provides consistency with control of quality. Determination and countering of the causes of errors will help eliminate many defects, enhance customer satisfaction, build confidence, and improve relationships in the long run between suppliers and end consumers.

Foster Continuous Improvement

Lean supply chain strategy is about continuous improvement. Companies with this mentality pursue the strategies of reaching out at a time to achieve a marginal advantage and motivating employees to participate, create, and show superior operating performance in order to produce long-term, sustained success in all operations and stages of supply chains.

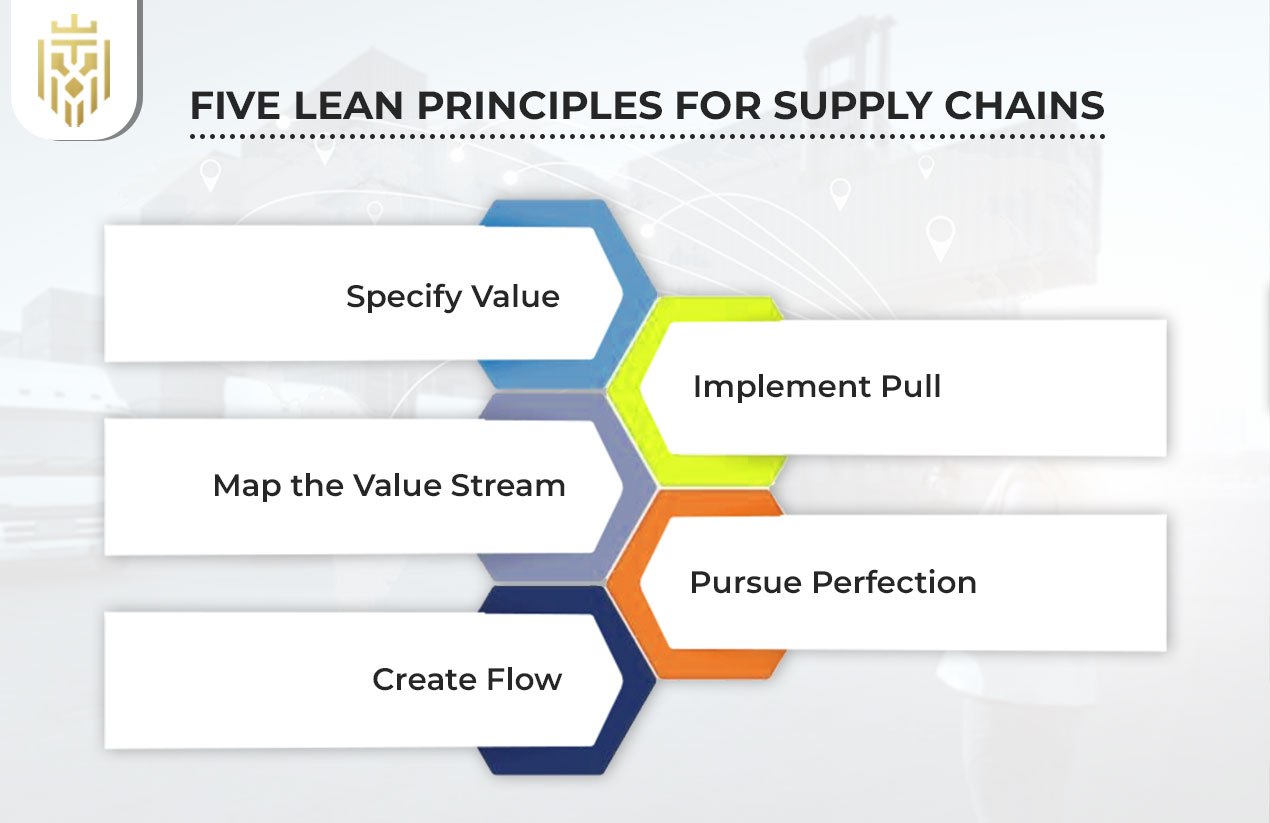

Five Lean Principles for Supply Chains

Lean supply chain management is based on the five lean principles: specifying value, mapping the value stream, creating flow, implementing pull, and pursuing perfection. These ideals enhance effectiveness, eliminate wastage, and create optimum value on complex supply networks.

Specify Value

The customer’s view of value is important in defining value in a lean supply system. When organisations prioritise value addition, the operations are aligned according to the actual requirements by ensuring reduced expenses and increased performance in the supply chain management.

Map the Value Stream

Mapping the value stream is helpful in efforts to define the supply chain, as it can help us to highlight wasteful activities. A visualisation of every step allows the enterprises to optimise the operations of the chain so that every step is dedicated to the delivery of the best products and services with the required speed and quality.

Create Flow

When a supply chain is created with flow present, this reduces the delays and bottlenecks. Companies also help in facilitating efficient transfer of materials and data to and between networks through streamlining and employing lean SCM.

Implement Pull

A lean supply chain adopts a pull-based method of production that is based on demand. It is a solution that eliminates high stock levels, lowers wastage, and keeps an organisation flexible in terms of production by adjusting its production to the current needs of the market as they occur.

Pursue Perfection

Organisations need to continuously improve operations through lean methodology in order to attain perfection. Constant evaluation, innovation, and vigilance are more than sufficient in keeping the direction of continuous advancement in progression to competitive advantage and high standards in the sphere of supply chain management.

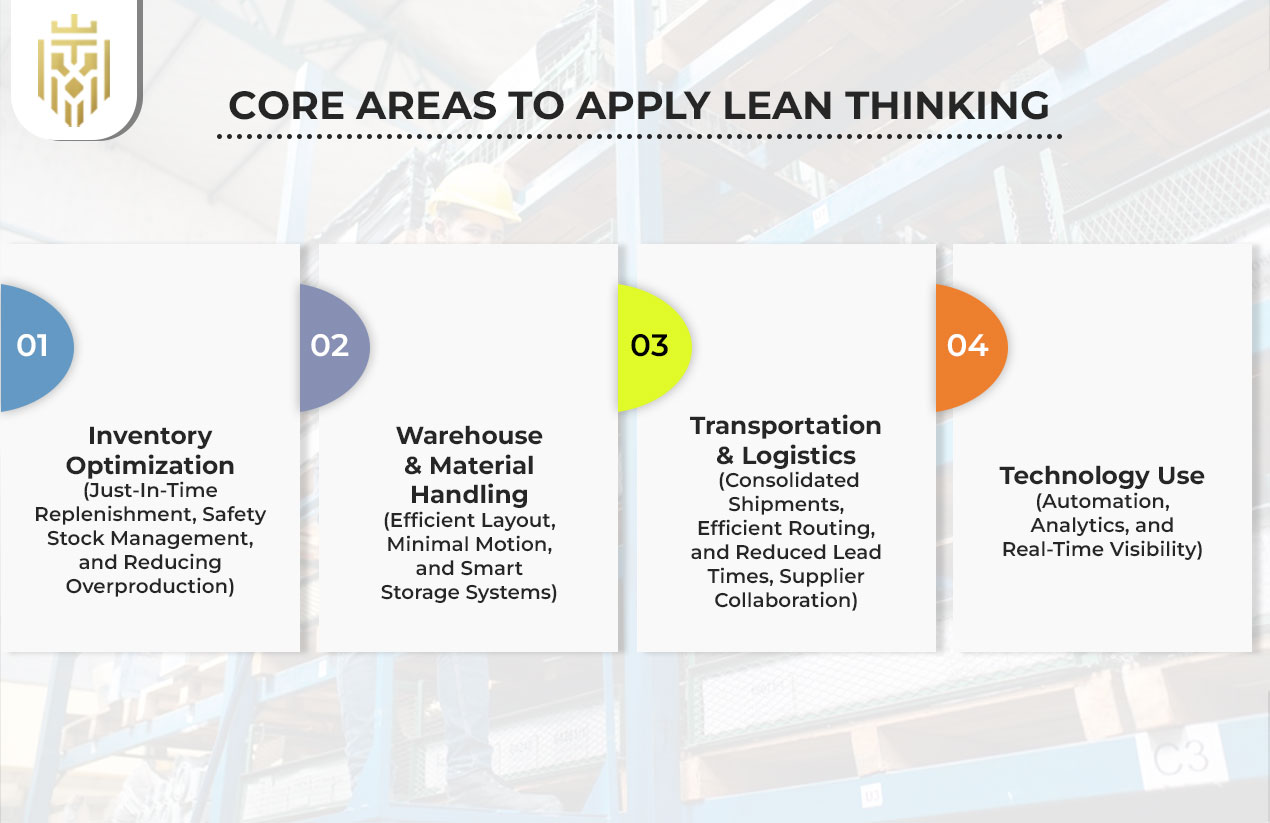

Core Areas to Apply Lean Thinking

Organisations can implement lean concepts in several functional capabilities of the business, such as procurement, manufacturing, and distribution. Employment of major priorities, such as optimisation of inventory and flow of the processes, is helpful to provide a stable and efficient lean supply chain that efficiently satisfies the needs of customers.

Inventory Optimisation

Lean concepts in supply chains help companies to optimise their stocks, balancing between supply and costs. Businesses can enhance their cash flow, save storage costs, and be more responsive throughout the supply chain by minimising waste and streamlining inventory operations.

Just-In-Time Replenishment

The just-in-time model, which is common in lean SCM, is used to guarantee that the materials are supplied when they are needed by the production process. This reduces inventory holding costs, avoids excess stocks, and leads to a greatly streamlined, efficient supply chain corresponding to veritable customer demands.

Safety Stock Management

A lean supply system ensures that risks of stockout are less and resources are not overstretched due to proper safety stock management. Measuring supply chain metrics and using analytics in business gives companies the opportunity to choose the right compromise, which creates reliability and stability in the management of supply chains.

Reducing Overproduction

Eliminating overproduction forms the main attraction of a lean supply chain, as it helps companies to avoid excessive inventory. When production is in sync with actual demand, supply chain management operations are efficient, and thus, waste is prevented, resources are optimised, and the overall operations’ sustainability is enhanced.

Warehouse & Material Handling

Supply chains are made up of warehouse operations. Applying such lean principles as efficient layouts and automation, companies can process easily, minimise downtime, and improve the accuracy of inventory, making the operations smoother throughout the whole supply chain.

Efficient Layout

Effective warehouse design is also used in chain management, which limits wasteful travelling and time. Appropriate use of spaces, streamlined paths of pickers, and neatly defined storage areas guarantee higher productivity and quick material flow, which is essential in a lean scenario of the supply chain.

Minimal Motion

Limitation of movement of workers saves on time and also on fatigue, hence enhancing performance in the supply chain management. Warehouse efficiency, safety, and productivity can all be enhanced by the analysis and redesign of workflows to increase efficiency and reduce the amount of unnecessary motion.

Smart Storage Systems

The lean SCM strategies provide smart storage, such as automated racking and vertical storage, that enhance the available space utilisation. A more efficient and reliable supply chain process is characterised by increased accessibility and shorter time to retrieve, as well as faster fulfilment within the systems.

Transportation & Logistics

Making lean supply chain management possible depends on transportation. Decisions such as route optimisation, combining shipments, and reducing turnaround times lower costs and enhance the reliability of the delivery, making supply chains effectively coordinated throughout the different levels.

Consolidated Shipments

Merging shipments decreases transportation expenditure and carbon footprint, which enhances the supply chain effectiveness. Businesses can save resources, enhance the delivery time, and improve performance in lean supply operations by putting smaller loads together in fewer trips.

Efficient Routing

The operation of effective routing is a must in the lean strategies of supply chains to reduce the cost of fuel and the time of travel. Through route-planning programs and real-time information, delivery companies can deliver on time without incurring higher operational costs and reliability.

Reduced Lead Times

A lean supply chain prospers on short lead times. Faster order fulfilment is achieved by maximising supplier coordination, speed of transportation, and handling in the warehouse. The strategy enhances both customer satisfaction and general responsiveness in the interrelated supply chains.

Supplier Collaboration

Developing partnerships with suppliers enhances chain management through transparency and consolidation. Online planning, live updates, and trust would facilitate a reduction in delay and issues in inventory and achieve efficiency in supply chain management structure conforming to lean principles.

Technology Use

In lean supply models, technology plays a key role in automating repetitive work and enhancing the accuracy of the same. The digital tools make data collection more efficient and increase supply chain visibility for quicker decision-making and better flexibility in fitting lean supply chain management objectives.

Use Automation

Automation minimises the number of human errors, improves efficiency in the supply chain, and accelerates the process of orders. Automated conveyors to robotic picking systems are all important facilitators of the lean SCM in the modern environment of logistics and warehouses.

Analytics

Analytics enables organisations to benchmark performance, detect inefficiencies, and make evidence-based decisions. The application of predictive insights in lean approaches to the supply chain would be in supplying the foremost anticipation, streamlined stocking, and increased consumer satisfaction following the lean ideals.

Real-Time Visibility

Real-time visibility enables organisations to respond promptly, facilitating an efficient flow in the supply chain. Companies can achieve improvements in operational control, which is directly related to the lean supply chain and its performance objectives, by incorporating tracking tools and IoT solutions.

Common Challenges & Balanced Solutions

Adoption of lean supply chain activities is associated with challenges like disturbances, recalcitrance, and the expense of high technological activities. To overcome these, there needs to be a balance between lean efficiency and resilience, innovation, and proactive problem solving in the supply chains.

Vulnerability to Disruptions

Although lean supply minimises high inventory, it exposes itself to unexpected disruption due to limited buffers and reduced safety stock levels. The introduction of strategic buffers and the diversity of suppliers, coupled with resilience in supply chain management, would help counter the risk and safeguard continuity in operations.

Too Much Rigidity

Agile practices enable companies to feel the market changes together with lean SCM practices. The combination of efficiency and responsiveness results in a way that the operations of the supply chain learn to change fast, and both the advantages of lean and competitive advantage are preserved.

Cultural Resistance

The resistance to new lean concepts by workplace culture is also a barrier. Organisations can support easier transitions and the effectiveness of supply chain management projects by using lean learning programs, engaging the stakeholders, and embracing a culture of innovation.

Technology Costs

Initial costs of technology investments used in the supply chain for lean improvements appear costly. Nevertheless, savings in the long term in terms of less wastage, automation, and improved forecasting are substantial, so the benefits outweigh the costs, and digital tools are the key to modern supply chains.

How to Launch a Lean Supply Chain in 5 Steps?

Selecting a lean supply chain includes a tactical plan—initially, value-stream analysis, measurable goals, and a technology combination. All the steps make the chain management processes more efficient with less wastage and improved responsiveness and customer satisfaction.

major consideration in the comprehension of inefficiencies in supply chain operations is value-stream analysis. Tracking every process would enable companies to spot problem areas and apply lean supply chain management to enhance flow, quality, and performance.

Set Measurable Lean Goals

Establishment of clear performance targets, such as inventory turns or even a reduction in the cycle time, will ensure that the supply chains are continuously improving. Such benchmarks match chain definition and spur success throughout lean supply efforts via centric, data-driven approaches.

Pilot Warehousing or Transport Improvements

Lean supply chain techniques can be tried out through small-scale work on the warehouse or transportation at the organisation. Such controlled experiments limit risks, pinpoint waste, and develop actionable insights that improve the overall performance of supply chain management before a broader rollout.

Scale Successful Practices

After pilots have been successful, companies adopt them in supply chains at scale to get repeatable efficiency. This entails applying the lean concepts of waste elimination, flow enhancement, and better resource utilisation across the different steps of managing chains.

Monitor and Refine Processes

Monitoring the supply chain helps in making its lean measures effective. Constant audits, records analysis, and stakeholder ratings can streamline processes, minimise delays, and overall improve operational success, which is an important aspect of being lean in supply chain management operations.

Real-Life Lean Success Stories

Examples of lean supply chains in action can be observed in real life. Organisations of every industry have adopted lean methods in order to minimise wastage and enhance responsiveness and customer happiness, which has made their supply chain more responsive and lower-cost.

Manufacturers Using Just-in-Time Delivery

The just-in-time delivery method implemented by manufacturers has saved them from the storage expenses due to the production matching the actual demand. This lean supply strategy helps to eliminate excess supply, optimise resources, and improve responsiveness in systems of supply chain management.

Retailers with Frequent Small Shipments

The retailers will attain efficiency through small and frequent deliveries whose sizes are matched with the demand profiles. This lean SCM practice mitigates stockouts, makes the best use of logistics expenditures, and ensures that the supply chain will be responsive as well as economical.

Left-Shifted Warehouse Setups

Centralisation of warehouse facilities nearer to the point of production lowers handling and accelerates the execution of orders. This is a lean strategy that enhances the movement of activities and generates quicker and more productive supply chains.

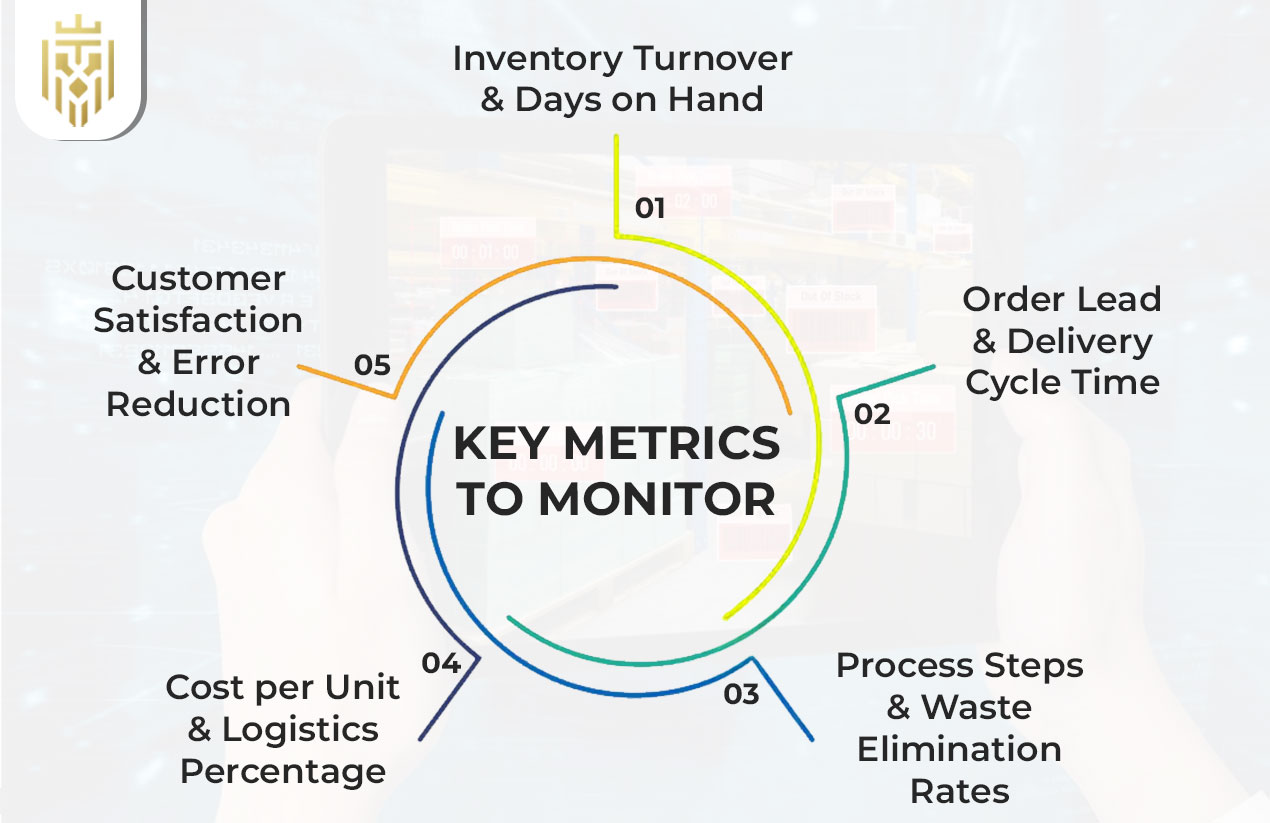

Key Metrics to Monitor

It is essential to measure progress to maintain a lean supply chain. Monitoring activities such as measures of performance, lead time, waste reduction, and logistic expenses will help make sure that the supply chain management always keeps pace with the lean improvement objectives.

Inventory Turnover & Days on Hand

Realistic, quick movement of the inventories and fewer days on hand indicate good supply chain functionality. These measures point to the adequacy of lean supply practices in ensuring stock caps, reducing waste, and liberating capital locked in stock.

Order Lead & Delivery Cycle Time

Minimising the order lead time and delivery cycle time is essential as part of efforts in supply chain lean. When businesses reduce delays and optimise processes, they have a greater chance to respond quickly to customer demands and increase satisfaction and competitiveness.

Process Steps & Waste Elimination Rates

Monitoring workflow steps allows for recognising bottlenecks and waste. The principles of lean supply chains enable chain management to be done cost-efficiently in a smoother way because of the reduction of processes that are not necessary.

Cost per Unit & Logistics Percentage

Watching the shipping costs and logistics expenses to the sales makes sure that the company is economically efficient. Lean supply chain management enables businesses to reduce their operational waste, improve transportation paths, and enhance price-effectiveness.

Customer Satisfaction & Error Reduction

Increasing customer satisfaction and cutting errors would be in line with the objectives of lean techniques. Succinctly tracking these metrics results in supply chains that provide consistent quality and yield befitting customer expectations.

Conclusion

The implementation of a lean supply chain leads to efficiency in operations, cost reduction, and responsiveness. Organisations can develop a high-performance, agile, and free supply chain through attention to chain definition metrics, the use of lean SCM, and the culture of continuous improvement.

FAQs

1) How is a lean supply chain different from an agile supply chain?

The lean supply chain is aimed at minimising waste, cost-effectiveness, and efficiency, whereas an agile supply chain is orientated at versatility, rapid reactions, and responsiveness to fast alterations in the market.

2) What is value-stream mapping?

Value-stream mapping is one of the tools of lean principles, which visualises and analyses any process steps. It selects waste, streamlines operations, and assists in increasing efficiency within the supply chain management business.

3) Can lean supply chains adapt to sudden disruptions?

Although lean supply chain minimises inert buffers, the practices may cope with any disruptions in the supply chain by including strategic contingency plans, supplier relationships, and flexible responses coupled with chain operation practices.

4) Which technologies help enable a lean supply chain?

A lean supply chain is possible through automation, real-time tracking, predictive analytics, and IoT. The technologies reduce processes and provide better visibility and decision-making in supply chain management environments.

5) How can a business start implementing lean practices?

To minimise waste, businesses can begin with value-stream analysis, established objectives, and lean supply tools. Involving employees and stakeholders through training will smooth the process of adopting lean SCM.

6) What is a lean supply chain?

Lean supply chain is a technique that targets waste elimination, process optimisation, and efficiency. Organisations use lean supply chain management to enhance cost-effectiveness and consumer satisfaction.