What is a Warehouse?

A warehouse is a big storehouse or a place used in storing goods, materials or products. It has a neutral role in the supply chain since it aids in storing and moving inventories. The warehousing definition incorporates the essence of being a centralized management location, which supports ecommerce, retailing, and manufacturing enterprises effectively.

Role of Warehouses in Supply Chain

The warehouses play an important role in the supply chain management. They keep the goods safely stored, process the inventory and allow distribution. These warehousing activities enhance speed of fulfillment, lower cost and maximize customer satisfaction, which highlights the key roles of warehousing in logistics operations to excellence.

Key Functions of Warehouses

Warehousing functions can be seen to provide storage, inventory management and distribution. The explained functions are beneficial in terms of optimizing supply chain performances. The three fundamental services of warehousing, which include storage space, protection of goods and flow management, add efficiency and save costs.

Storage of Goods

Warehouses are safe places where goods can be stored to avoid damage and losses. It is one of the three fundamental uses of warehousing, without which supply chains would not be able to operate. The above explained functions demonstrate the effects of space utilization on ecommerce, distribution and inventory management.

Managing Inventory

Some of the key warehousing operations include inventory management, whereby supply is equated with demand. This important warehousing activity helps to optimize storage space, reduce inventory and improve the overall effectiveness of the supply chain. The cost control and customer experience are enhanced due to the real-time updates and forecasting.

Facilitating Logistics

Warehouses are logistic centers in which goods can be received, put away, picked and dispatched. Such are the warehousing functions in logistics without which the chain of supply would be broken. When it is well executed, it allows timely delivery, efficient inventory movement and the general management of distributions.

Supporting Distribution

With warehousing, distribution is aided by sorting, storage as well as dispatching of goods in an efficient manner. This is a crucial role of warehousing in which the correct order processing and dispatch happen. It is also helpful in ecommerce business to speed delivery, cut overhead and ensure products are supplied as demanded.

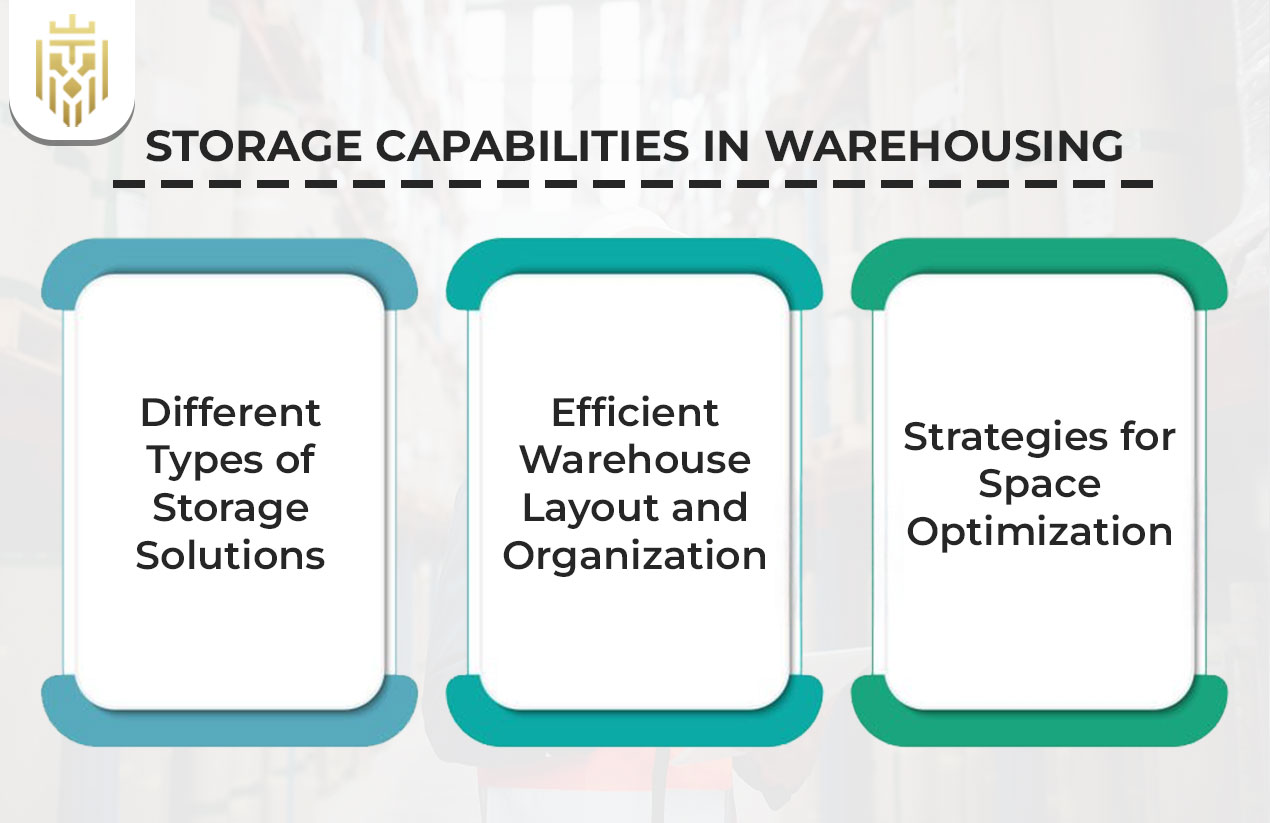

Storage Capabilities in Warehousing

Warehouses seek high-tech storage options such as pallet racking, shelving, and automation. These warehousing operations provide safe keeping of products, inventory turnover, and elastic management which are of value to e commerce, retail, and manufacturing enterprises.

Different Types of Storage Solutions

Various kinds of warehousing systems like pallet racks, and AS/RS systems assist in the systematic storage of goods. These increase the use of space and enhance management. The appropriate choice of types of storage is an ability to optimize workflow, which is one of the crucial aspects of warehousing functions in logistics.

Efficient Warehouse Layout and Organization

A well structured layout is essential in efficient management and storage of goods. The use of vertical space, automation and clear areas facilitates warehousing operations and quickens the activities. The functions of warehousing are promoted through efficient design, facilitating quick picking, packing and smooth flow of supply chain.

Strategies for Space Optimization

Space optimization enhances operations of warehousing as it allows to store goods more efficiently, minimize clutter and increase accessibility. Automated systems and strategic layouts improve inventory management which is crucial to ecommerce and responsiveness to supply. This guarantees constant stock and reduced process time delays.

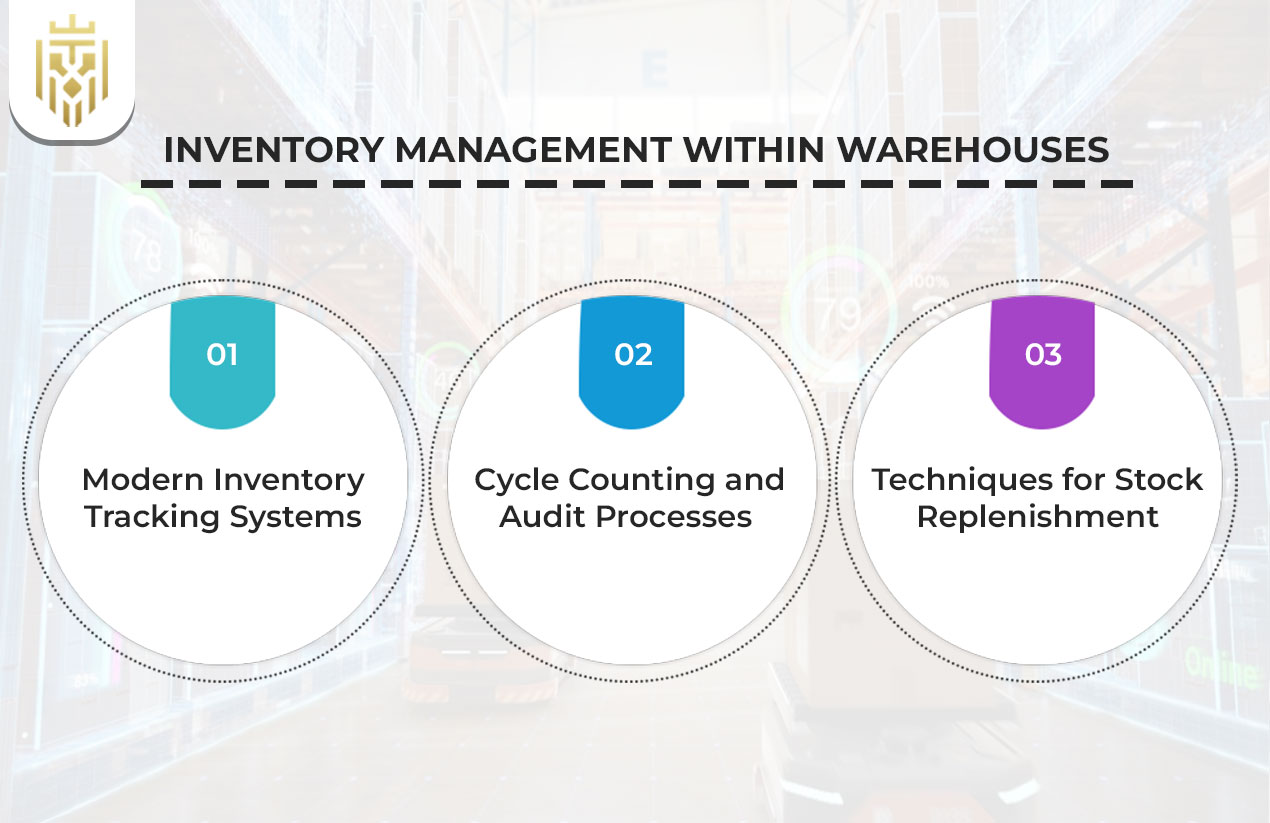

Inventory Management within Warehouses

One of the essential elements of warehousing functions in logistics is inventory management. Completely correct tracking, replenishment, as well as audits avoid stock problems and makes the supply chain more effective, which improves responsiveness, reduces losses, and improves the efficiency of warehousing activities with diverse kinds of operations.

Modern Inventory Tracking Systems

The RFID and Barcodes are modern systems which are functions of warehousing that enhance real time management of inventory. Such technologies increase visibility, accuracy and can aid in streamlining the supply chain. These innovations represent the main advantages to be offered to developing ecommerce businesses.

Cycle Counting and Audit Processes

Audits and cycle counting keep inventory accuracy at a high level and enhance warehousing operations. Verification on a regular basis will avoid numerous mistakes and losses because of correct storage of goods. This warehousing operation is an on-going process which helps in the continuing betterment of the supply chain and enhancement of general warehouse management.

Techniques for Stock Replenishment

Stock replenishment techniques such as reorder points and forecasting are included in the basic warehousing activities. These guarantee even distribution of products, and there is no overstocking or stock out. Management based on technology enhances accuracy and effectiveness in satisfying ecommerce throughout the supply chain.

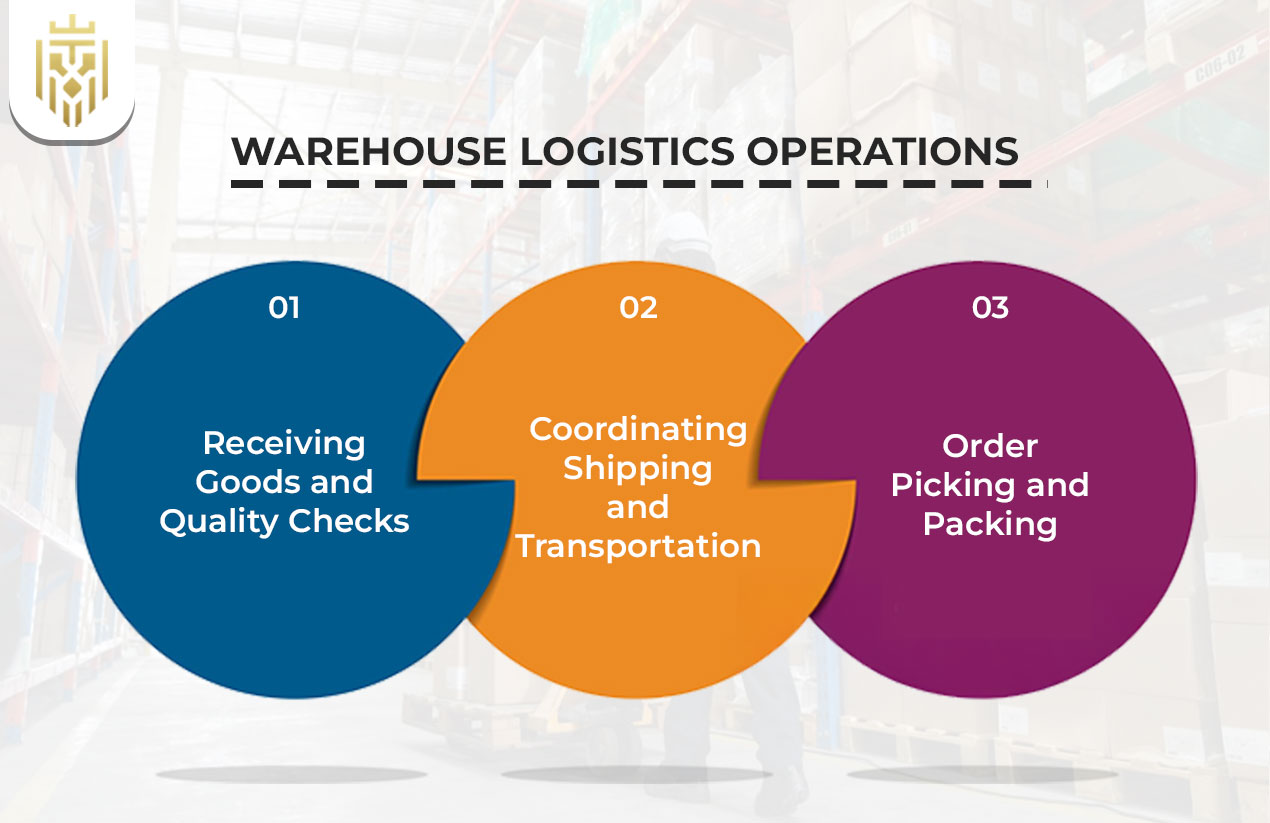

Warehouse Logistics Operations

Warehouse logistics operations comprises unloading incoming goods, quality control, selection and dispatch. These warehousing services play an important role in effective supply chain flow and management which creates timely delivery, order accuracy and easy coordination between warehouses and transportation providers.

Receiving Goods and Quality Checks

The important warehousing roles in logistics are the receipt and inspection of goods. This involves receiving goods, checking the quality and storing them appropriately to ensure accuracy in the inventory. These functions described imply a smoother operation of logistics and the certain product flow in the supply chain.

Coordinating Shipping and Transportation

One of the most important uses of warehousing is Shipping coordination where goods pass quickly along the supply chain. This involves the coordination of the transportation times, tracking and last mile delivery. This kind of management facilitates effective ecommerce business and delivery of the goods to the customers promptly.

Order Picking and Packing

Warehousing essential activities involved in the correct fulfillment of orders include picking and packing. Goods can be handled efficiently, which minimizes delays and mistakes. These warehousing operations improve the supply chain process, which is significant to ecommerce customer satisfaction and loyalty.

Distribution Services Provided by Warehouses

Warehousing distribution services encompass order fulfillment, cross-docking and last-mile delivery. They are services that minimize time in transit, enhance responsiveness of ecommerce and reinforce supply chain networks. With effective management, the supply of goods to the customers will be fast regardless of the category of the market.

Managing Order Fulfillment Services

Warehouses are advantageous because they do the entire order fulfillment business; they receive, store and ship merchandise. Such warehousing operations play a critical role in ecommerce development and guarantee stability of supply. With competent management, the supply-chain is well-oiled and delivery is expedited and predictable.

Streamlining Cross-Docking Processes

Cross-docking is a value added service of warehousing which minimizes the storage time as the incoming goods are directly loaded into the outbound transportation. This increases the efficiency of the supply chain and removes unessential handling. It’s a huge advantage to time-based ecommerce businesses that require fast turn-around.

Handling Last-Mile Delivery

Warehouses allow optimizing the last-mile delivery by organizing the process of picking items, packing, and shipping. Such warehousing operations guarantee fast delivery of goods to the final clients, improving ecommerce experience. Effective control of this activity of warehousing contributes towards a stable and customer oriented supply chain.

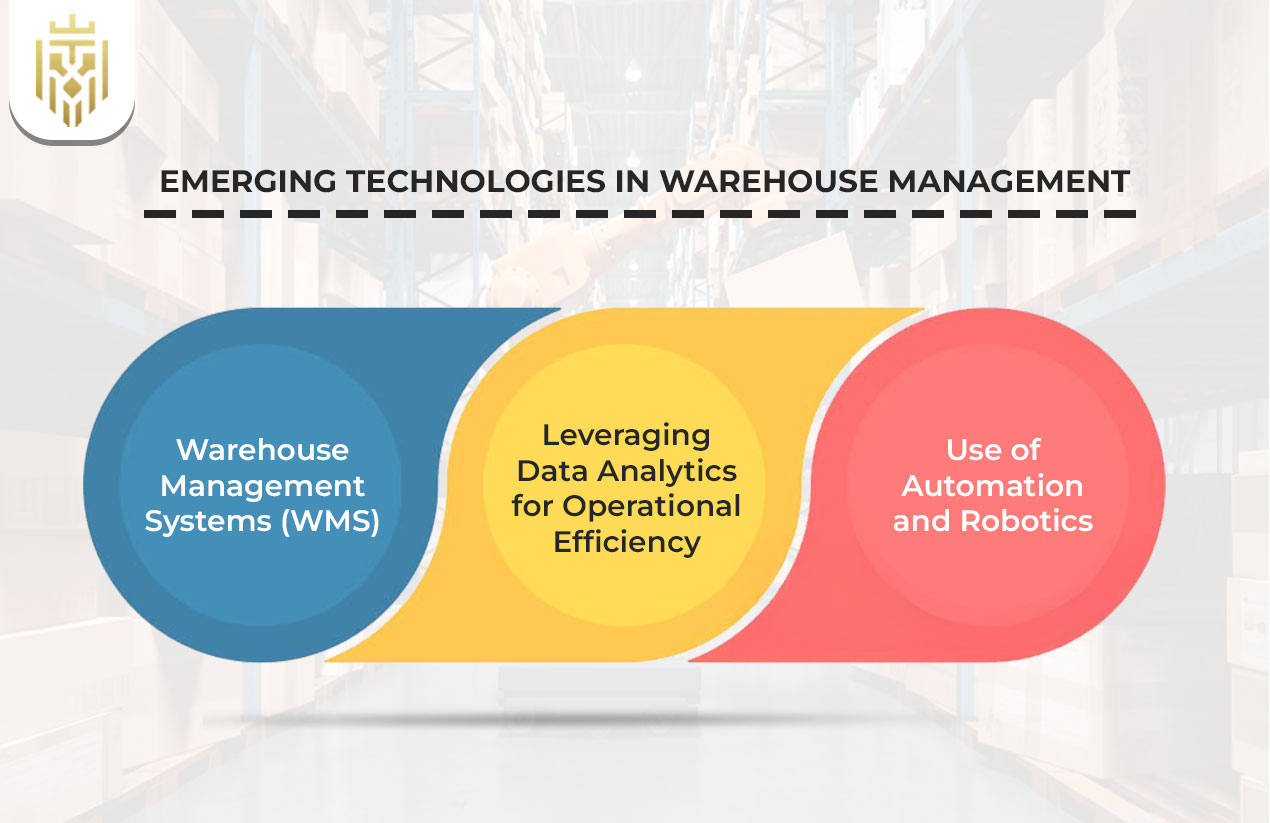

Emerging Technologies in Warehouse Management

Technologies such as WMS, robotics, and AI transform warehousing roles in logistics. These new technologies improve management, automate storage, and improve the visibility of goods in the supply chain to raise accuracy, efficiency, and overall performance of the modern warehouses.

Warehouse Management Systems (WMS)

The contemporary WMS systems are revolutionizing the warehousing operations by using AI, robotics, and automation. The tools are efficient in storage of goods, labor, and processing of orders. Warehouses that adopt tech enjoy efficiencies created, as well as the opportunity to become a force in the digital supply chain ecosystem.

Leveraging Data Analytics for Operational Efficiency

Data analytics is useful in real time decision making regarding the management of the warehouse to provide a better forecasting and stock maintenance. Such roles of warehousing in logistics enhance accuracy and speed, which offer strategic advantages in ecommerce fulfillment, inventory management, and general supply optimization.

Use of Automation and Robotics

Robotics and automation are transforming the roles of warehousing to enhance the accuracy of storage, minimizing the cost of labor and maximizing throughput. The innovation has operational advantages, where operations of warehousing can be more tenable to high volume ecommerce and global supply chain needs.

Why Efficient Warehouse Operations Matter?

An effective warehousing limits the cost, increases the velocity of delivery and enhances customer satisfaction. These are the core warehousing functions in responsive supply chain systems, and they provide evident advantages to any business through the simplification of management and guarantee of the consistent availability of goods.

Gaining a Competitive Edge in the Market

Effective warehouse management is a competitive advantage providing a smooth flow of goods in the warehouse, proper storage, and quick fulfillment. These fundamental services of warehousing simplify the chain of supply which enables business to adjust to the market demand and improving their ecommerce presence.

Enhancing Customer Experience

Streamlined warehousing operations ensure accuracy and on-time delivery of orders, which boosts the ecommerce customer experience. The proper storage and inventory management enables the smooth execution of the supply chain that meets the expectations and builds long-term customer loyalty.

Driving Down Operational Costs

One of the best advantages of simplified functions of warehousing comprises cost efficiency. By minimizing storage space, automation and intelligent management, warehouses can trim overheads, labor and delays-directly enhancing bottom-line performance throughout the supply chain, and helping to deliver improved ecommerce service.

FAQs

1.What are the four major types of warehousing?

There are four main categories of warehousing: a private warehouse, a public warehouse, a bonded warehouse, and a distribution center. The two types fulfill particular requirements of storage, handling and transportation of products in the supply chain.

2.What are the functions of warehouse management?

Warehouse management functions can be subdivided into inventory management, space management, order fulfillment management and labor management. The above described functions will result in better storage, cost reduction, and the free movement of goods through the supply chain and the ecommerce routes.

3.What is the role of a warehouse in the supply chain?

A warehouse is an important element of supply chain as it stores goods, maintains their inventory and distributes them. It makes sure that the goods are available, logistics performs efficiently, and overall warehousing operations and business administration are improved.

4. Is warehousing part of logistics?

Yes, warehousing belongs to the logistics, which deals with storage, otherwise known as inventory handling and distribution. It facilitates warehousing operations in logistical operations where goods are optimally stored and transferred through the supply chain to be delivered on time.